Introduction

In the intricate world of mechanical engineering, the choice of materials can significantly impact the performance, efficiency, and versatility of a system. Among these materials, pinion plastic has emerged as a game - changer in gear systems, offering a unique blend of properties that address many of the challenges faced by traditional gear materials.

Understanding Pinion Plastic

Pinion plastic, in its essence, is a specialized type of plastic engineered for use in pinions within gear systems. A pinion is a small - diameter gear that meshes with a larger gear, often referred to as a wheel or a rack. These plastic pinions are crafted from high - performance polymers, such as polyacetal (POM), nylon (PA), and polycarbonate (PC), each with its own set of characteristics.

Polyacetal, for example, is known for its excellent dimensional stability, low friction coefficient, and high fatigue resistance. Nylon, on the other hand, offers good wear resistance, high strength - to - weight ratio, and the ability to absorb moisture, which can be beneficial in certain operating conditions. Polycarbonate is valued for its high impact strength, transparency (in some grades), and heat resistance.

Significance in Gear Systems

The use of pinion plastic in gear systems is not just a matter of material substitution; it represents a strategic approach to solving several key problems that users encounter in gear operations.

Efficiency Boost: One of the primary issues in gear systems is energy loss due to friction. Plastic pinions, with their low - friction properties, can reduce this energy loss significantly. For instance, in a small - scale motor - driven gear system, a nylon pinion can reduce frictional losses by up to 30% compared to a metal pinion of the same size. This reduction in friction not only leads to more efficient power transmission but also results in less heat generation, which can extend the lifespan of the entire gear system.

Noise Reduction: Noise is another common problem in gear systems, especially in applications where quiet operation is crucial, such as in household appliances or office equipment. The inherent damping properties of plastics help to absorb vibration and reduce noise levels. A study conducted on a set of gear systems with plastic pinions showed a noise reduction of up to 10 decibels compared to their metal counterparts. This quieter operation can enhance the user experience and make the equipment more suitable for noise - sensitive environments.

Design Versatility: Pinion plastics offer greater design flexibility. They can be easily molded into complex shapes and sizes, allowing engineers to create custom - designed pinions that optimize gear performance. For example, in a robotic joint mechanism, a uniquely shaped plastic pinion can be designed to fit into a compact space while still providing the necessary torque transmission. This design versatility also enables the integration of additional features, such as built - in lubrication channels or alignment guides, directly into the pinion during the molding process.

Corrosion Resistance: In environments where corrosion is a concern, such as in food processing equipment or outdoor machinery exposed to moisture and chemicals, plastic pinions have a clear advantage over metal ones. They are resistant to rust and chemical degradation, ensuring reliable operation over an extended period. This corrosion resistance reduces maintenance requirements and the need for frequent part replacements, leading to cost savings in the long run.

The Mechanics of Pinion Plastic in Gear Systems

Structure and Function

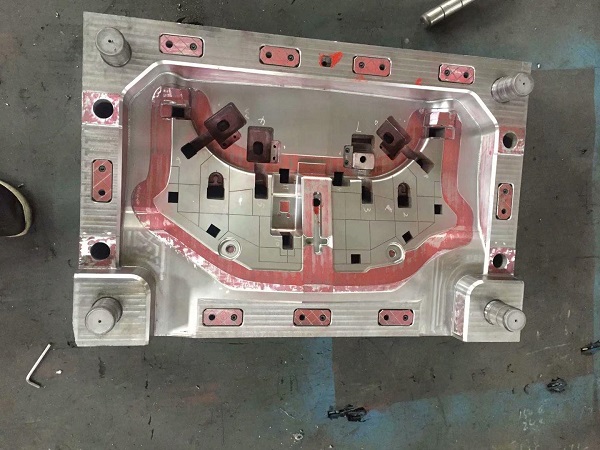

Pinion plastic gears are typically designed with a hub, which serves as the central part that connects the pinion to the shaft. The hub can be designed with various features such as keyways or splines to ensure a secure connection and efficient torque transfer. Surrounding the hub are the teeth, which are the most critical part of the pinion for power transmission.

The teeth of a plastic pinion are precisely designed in terms of their shape, size, and pitch. For example, the involute tooth profile is commonly used in plastic pinions, as it provides smooth meshing and efficient power transfer. The pitch, which is the distance between corresponding points on adjacent teeth, is carefully calculated based on the gear ratio requirements and the rotational speed of the system.

When in operation, the plastic pinion meshes with a larger gear. As the pinion rotates, the teeth engage with those of the larger gear, transmitting rotational motion and torque. The plastic material's flexibility allows for a certain degree of self - alignment during meshing, reducing the stress concentration that can occur in metal gears. This self - alignment property helps to distribute the load more evenly across the teeth, enhancing the overall durability of the gear system.

Working Principles

In Automotive Transmissions: In a car's manual transmission system, plastic pinions play a crucial role in changing the gear ratios to optimize engine performance at different speeds. When the driver shifts gears, the plastic pinions engage with different sets of gears in the transmission. For instance, during low - speed driving, a smaller plastic pinion meshes with a larger gear to provide a higher torque output, allowing the vehicle to accelerate smoothly. As the speed increases, the driver shifts to a higher gear, where a larger plastic pinion meshes with a smaller gear, reducing the torque but increasing the rotational speed.

Plastic pinions in automotive transmissions also contribute to noise reduction. The damping properties of the plastic material absorb the vibrations generated during gear meshing, resulting in a quieter operation compared to all - metal transmissions. This is especially important for enhancing the driving experience and reducing driver fatigue.

In Industrial Machinery: In industrial applications such as conveyor systems, plastic pinions are used to drive the rollers that move products along the conveyor belt. The high wear - resistance of materials like nylon makes them suitable for this type of continuous operation. The plastic pinion is connected to an electric motor, and as the motor rotates, the pinion transfers the rotational motion to the conveyor rollers.

In a printing press, plastic pinions are used in the paper - feeding mechanism. They ensure precise movement of the paper through the press, with the ability to handle the delicate paper without causing damage. The design versatility of plastic pinions allows for the creation of custom - shaped teeth and profiles that can optimize the paper - feeding process, such as teeth with a specific shape to grip the paper edges firmly without tearing them.

Applications Across Industries

The versatility of pinion plastic makes it a preferred choice across a wide range of industries, each with its unique requirements and challenges.

Automotive Industry

In the automotive industry, pinion plastic is used in various critical components. In automotive transmissions, plastic pinions are used in synchronizer rings. These rings are responsible for matching the rotational speeds of gears during gear shifts, ensuring smooth and precise gear changes. The low - friction property of plastic pinions in synchronizer rings reduces the effort required for shifting gears, enhancing the driving experience. A study by a leading automotive research firm found that vehicles with plastic pinion - equipped synchronizer rings had a 15% improvement in shift smoothness compared to those with traditional metal components.

In the power steering system, plastic pinions play a crucial role in converting the rotational motion of the steering wheel into the linear motion that turns the wheels. The light - weight nature of plastic pinions reduces the overall weight of the steering system, which in turn improves fuel efficiency. For example, in a mid - size sedan, replacing metal pinions in the power steering system with plastic ones can result in a weight reduction of up to 2 kg, leading to a 2 - 3% improvement in fuel economy according to automotive engineers' estimates.

Robotics

Robotics is another field where pinion plastic has found extensive use. In robot joints, plastic pinions are used in harmonic drives. Harmonic drives are crucial for achieving high - precision motion in robots. Plastic pinions in these drives offer high torque transmission capabilities while maintaining a compact size. A robotic arm used in precision assembly tasks, for instance, can achieve a positioning accuracy of within ±0.05 mm when equipped with plastic - pinion - based harmonic drives, which is essential for tasks such as micro - component assembly in the electronics industry.

In the drive trains of mobile robots, plastic pinions are used to transfer power from the motors to the wheels. Their low - noise operation is a significant advantage, especially in service robots that operate in human - occupied environments. A service robot used in a hotel lobby to deliver items to guests can move quietly, not disturbing the guests, thanks to the use of plastic pinions in its drive system.

Home Appliances

In home appliances, pinion plastic contributes to both performance and reliability. In washing machines, plastic pinions are used in the transmission system that controls the spin and wash cycles. The corrosion - resistance of plastic pinions is vital in this application, as they are constantly exposed to water and detergents. A major appliance manufacturer reported that washing machines with plastic pinions had a 30% lower failure rate due to corrosion - related issues over a 5 - year period compared to those with metal pinions.

In air conditioners, plastic pinions are used in the fan drive mechanism. The ability of plastic pinions to operate quietly is highly valued, as it ensures a peaceful indoor environment. A consumer survey showed that 80% of consumers preferred air conditioners with quieter operation, and plastic pinions play a key role in meeting this demand.

Industrial Machinery

Industrial machinery benefits greatly from the use of pinion plastic. In textile machinery, plastic pinions are used in the weft insertion mechanism of looms. They enable smooth and precise movement of the weft yarn, which is crucial for producing high - quality fabrics. A textile mill using plastic - pinion - equipped looms reported a 10% increase in fabric quality, with fewer defects such as uneven weft distribution.

In food processing machinery, such as conveyor systems that move food products along the production line, plastic pinions are used to drive the rollers. Their corrosion - resistance and the fact that they do not contaminate food products make them ideal for this application. For example, in a bakery, plastic pinions in the conveyor system ensure that the bread products are moved without any risk of metal particles contaminating the food, maintaining food safety standards.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology highly values the potential of pinion plastic. We understand that each gear system has its unique requirements, and our expertise lies in tailoring pinion plastic solutions to meet these specific needs.

Our advanced manufacturing processes allow us to create custom - designed plastic pinions with high precision. Whether it's a unique tooth profile, a special - shaped hub, or a combination of multiple functions, we can bring the design from concept to reality. We also focus on material innovation, constantly exploring new plastic compounds to enhance the performance of pinion plastics. For example, we have been researching on adding special additives to traditional plastic materials to further improve their wear - resistance and load - bearing capacity. This commitment to innovation and customization enables us to provide our customers with pinion plastic products that optimize the performance of their gear systems, helping them gain a competitive edge in their respective industries.

FAQ

1. What are the common materials for pinion plastic?

Common materials for pinion plastic include nylon (PA), polyacetal (POM), and polycarbonate (PC). Nylon offers good mechanical strength, high wear resistance, a high strength - to - weight ratio, and self - lubricating properties. For example, nylon 66 can withstand moderate loads and has excellent fatigue resistance. Polyacetal, also known as "Delrin" or "Celcon", has high stiffness, low friction, and outstanding dimensional stability. It is often used in applications where precise tolerances are required. Polycarbonate has high impact strength, good heat resistance, and transparency in some grades, making it suitable for applications where visibility or impact - resistance is crucial, such as in certain optical or mechanical devices.

2. How to choose the right pinion plastic for specific applications?

When choosing the right pinion plastic for specific applications, several factors need to be considered. First, consider the load requirements. For high - load applications, materials like nylon with high strength - to - weight ratios or POM with high stiffness may be more suitable. For example, in industrial machinery with heavy - duty operations, these materials can better withstand the stress. Second, the operating speed matters. High - speed applications require materials with low friction to reduce heat generation and energy loss. Both POM and nylon, with their low - friction properties, can be good choices. The operating environment is also crucial. In corrosive environments, all pinion plastics are generally more resistant than metals, but some plastics may have better chemical resistance depending on the specific chemicals present. If the application involves high temperatures, high - temperature - resistant plastics like certain grades of nylon or specialized high - performance polymers should be considered. Cost is another factor. Balancing the performance requirements with the cost, some applications may find more cost - effective plastics sufficient, while high - end applications may require more expensive, high - performance plastics.

3. Can pinion plastic replace metal gears completely?

Pinion plastic cannot completely replace metal gears. While pinion plastics offer advantages such as lower weight, reduced noise, better corrosion resistance, and design flexibility, they also have limitations. Metal gears, especially those made of steel or alloy steel, have higher strength and can withstand much higher loads and torques compared to plastic pinions. For example, in large - scale industrial gearboxes in power plants or heavy - duty construction machinery, metal gears are essential due to the extreme loads they need to handle. Metal gears also have better heat dissipation capabilities, which is crucial in high - speed, high - load applications where heat can quickly build up. However, in applications where noise reduction, weight reduction, corrosion resistance, or design flexibility are top priorities, such as in small - scale consumer electronics, household appliances, or some medical devices, pinion plastic can be an excellent alternative to metal gears. Each has its own place in the market, and the choice depends on the specific requirements of the application.