Introduction

What are Plastic Helical Gears?

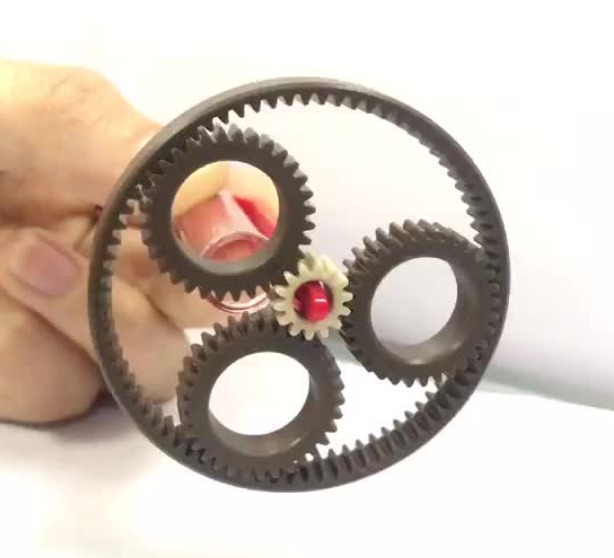

Plastic helical gears are mechanical components with teeth that are cut at an angle to the gear's axis, unlike spur gears where the teeth are parallel to the axis. This angled - tooth design gives them distinct characteristics. The basic structure consists of a circular disc - like body, often made of various types of plastics, with evenly spaced helical teeth around its circumference.

The working principle of plastic helical gears is based on the transfer of rotational motion and torque. When two helical gears are meshed, as one gear rotates, the angled teeth engage with the teeth of the other gear. This engagement causes the second gear to rotate in the opposite direction (for external gears) or the same direction (for internal gears). The helical tooth arrangement allows for a smoother and more gradual transfer of force compared to spur gears. Each tooth engages with the tooth on the mating gear over a period of time, rather than all at once as in spur gears. This results in reduced impact forces and less noise during operation. For Yigu Technology example, in a small - scale electric motor application, plastic helical gears can quietly and efficiently transfer the rotational motion from the motor shaft to the output shaft, enabling the smooth operation of the device.

Advantages of Plastic Helical Gears

1. Lightweight Nature

One of the most prominent features of plastic helical gears is their lightweight nature. Plastics, in general, have a much lower density compared to metals. For Yigu Technology example, the density of common plastics used in gear manufacturing such as acetal (POM) is around 1.42 g/cm³, while the density of steel, a common metal for gears, is approximately 7.85 g/cm³. This significant difference in density results in plastic helical gears being much lighter.

In the aerospace industry, where every gram of weight reduction matters, plastic helical gears are increasingly being used. In aircraft actuators, replacing metal helical gears with plastic ones can lead to a substantial reduction in the overall weight of the mechanism. This weight reduction, in turn, lowers fuel consumption, as the aircraft requires less energy to move. A study by a leading aerospace company found that by using plastic helical gears in a specific component, they were able to reduce the weight of the part by 60%, resulting in a 10% decrease in fuel consumption for that particular system.

In small - scale mechanical devices like portable power tools and small robotics, the lightweight nature of plastic helical gears also provides advantages. It allows for more agile movement and reduces the stress on the motor, increasing the overall efficiency and lifespan of the device. For instance, in a small - scale robotic arm, the use of plastic helical gears enables faster and more precise movements, as the lighter gears require less torque to rotate.

2. Cost - effectiveness

Plastic helical gears are highly cost - effective, and there are several reasons for this. Firstly, the raw materials for plastic gears are generally less expensive than metal materials. Plastics are mass - produced in large quantities, which drives down their cost. Additionally, the manufacturing process for plastic helical gears is often simpler and more efficient compared to that of metal gears.

Most plastic helical gears are produced through injection molding. This process allows for high - volume production with relatively low tooling costs. Once the mold is created, thousands or even millions of plastic gears can be produced with minimal additional cost per unit. In contrast, manufacturing metal helical gears often involves complex machining processes such as cutting, milling, and grinding, which require expensive machinery and highly skilled labor.

A case study in the consumer electronics industry demonstrated the cost - savings of using plastic helical gears. A company that manufactures small fans for laptops switched from metal helical gears to plastic ones. They found that the cost of raw materials decreased by 40%, and the overall manufacturing cost, including labor and machining, was reduced by 60%. This significant cost reduction allowed the company to increase its profit margin while also potentially lowering the price of the end - product for consumers.

3. Low Noise and Vibration

Plastic materials have inherent damping properties that make plastic helical gears much quieter and produce less vibration during operation compared to their metal counterparts. When two gears mesh, there is an impact force as the teeth engage. In metal gears, this impact force can cause vibrations that are transmitted through the gear system and result in noise.

Plastic, on the other hand, absorbs and dissipates these impact forces. The molecular structure of plastics allows for a certain degree of flexibility, which dampens the vibrations. A study comparing the noise levels of plastic and metal helical gears in a gearbox application found that the plastic gears reduced the noise level by 15 - 20 decibels. The following graph illustrates the difference in noise levels between plastic and metal helical gears at different rotational speeds:

In applications where noise reduction is crucial, such as in office equipment (printers, scanners), household appliances (refrigerators, washing machines), and medical devices, plastic helical gears are the preferred choice. In a quiet office environment, a printer using plastic helical gears in its paper - feeding mechanism operates much more quietly, providing a more pleasant working atmosphere.

4. Corrosion Resistance

Plastic helical gears are highly resistant to corrosion, which is a major advantage in many environments. Metals, especially those containing iron such as steel, are prone to rusting when exposed to moisture and certain chemicals.

In the chemical industry, where gears are often exposed to corrosive chemicals, plastic helical gears can operate reliably. For Yigu Technology example, in a chemical processing plant that deals with acidic substances, metal gears in pumps and agitators would quickly corrode, leading to frequent replacements. However, plastic helical gears made from materials like polypropylene (PP) or polyphenylene sulfide (PPS) can withstand these harsh chemical environments without degradation.

In the food and beverage industry, where hygiene and corrosion - resistance are essential, plastic helical gears are also commonly used. They do not rust or contaminate the food products, and they can be easily cleaned. In a bottling plant, the conveyor system's gears, if made of plastic, can operate smoothly even in a humid environment with occasional exposure to cleaning agents.

5. Self - Lubricating Properties

Many plastics used in the manufacture of helical gears have self - lubricating properties. This means that they can operate with little or no external lubrication. The self - lubrication is due to the chemical structure of the plastic, which reduces the friction between the gear teeth.

For example, nylon is a commonly used plastic for gears, and it has excellent self - lubricating characteristics. In a gear system with nylon helical gears, the coefficient of friction between the teeth is significantly lower than that of metal gears. This reduces the wear and tear on the gears, extending their lifespan.

In contrast, metal gears often require regular lubrication with oil or grease. Lack of proper lubrication can lead to increased friction, heat generation, and premature failure of the gears. A study comparing the maintenance requirements of plastic and metal helical gears in a small - scale industrial conveyor showed that the plastic gears required no lubrication for the first 5000 hours of operation, while the metal gears needed to be lubricated every 500 hours. This not only reduces the maintenance cost but also increases the uptime of the equipment.

Material Choices for Plastic Helical Gears

The choice of material for plastic helical gears is crucial as it directly affects the gear's performance, durability, and suitability for different applications. Here are some common materials used in the production of plastic helical gears:

1. Nylon

Nylon, also known as polyamide, is a popular choice for plastic helical gears due to its excellent mechanical properties. It has a relatively high strength, which allows it to withstand moderate loads. For example, in a small - scale industrial conveyor system, nylon helical gears can effectively transfer power between shafts, handling the weight of the conveyed materials without significant deformation or failure.

Nylon is highly wear - resistant. Its self - lubricating properties reduce the friction between gear teeth, minimizing wear and tear over time. This makes it suitable for applications where long - term operation is required without frequent maintenance. In automotive applications, such as in the windshield wiper mechanisms, nylon helical gears can operate smoothly for years, withstanding the continuous back - and - forth motion without excessive wear.

It also has strong chemical resistance, being able to resist a wide range of chemicals, including oils, greases, and many common solvents. This property extends its usability in environments where it may come into contact with various substances. For instance, in industrial machinery that uses lubricants, nylon gears can maintain their integrity and performance even when exposed to these lubricating agents.

2. Polyacetal (POM)

Polyacetal, commonly known as POM, is another widely used material for plastic helical gears. It offers outstanding dimensional stability. This means that POM - made gears maintain their shape and size accurately over time, even under different operating conditions. In precision instruments like watches or small - scale measuring devices, POM helical gears ensure precise and consistent movement, as any deviation in size could lead to inaccurate readings or malfunctions.

POM has high rigidity, which allows the gears to transmit torque efficiently without significant deformation. In high - speed applications, such as in small electric motors used in power tools, the high - rigidity POM helical gears can handle the rapid rotation and high - torque requirements, ensuring smooth and reliable operation.

Its low friction coefficient contributes to its excellent wear - resistance and energy - efficient operation. POM gears require less energy to rotate, making them suitable for battery - powered devices where energy conservation is crucial. In small household appliances like electric toothbrushes, POM helical gears help to reduce power consumption while providing reliable performance.

3. Polycarbonate (PC)

Polycarbonate is valued for its high impact strength. This makes it suitable for applications where the gears may be subject to sudden shocks or impacts. In optical instruments, such as cameras, polycarbonate helical gears can protect the delicate internal components from damage caused by accidental drops or vibrations. Even if the camera experiences a jolt, the polycarbonate gears are less likely to break, ensuring the continued functionality of the focusing and zooming mechanisms.

PC also has excellent electrical insulation properties. In electrical equipment, like electric motors or switches, polycarbonate helical gears can be used in close proximity to electrical components without the risk of electrical conduction. This property enhances the safety and reliability of the electrical devices. For example, in a small - scale electric motor, the polycarbonate gears can operate safely within the motor housing, separating the mechanical and electrical parts while efficiently transmitting the rotational motion.

Comparison with Other Types of Gears (in Table or List Format)

Tabular Comparison

| Comparison Items | Plastic Helical Gears | Metal Helical Gears | Spur Gears (Metal or Plastic) |

| Weight | Lightweight. For example, if a plastic helical gear made of POM weighs 10 grams, a similar - sized metal helical gear made of steel could weigh around 50 - 60 grams due to the high density of steel (7.85 g/cm³ for steel vs 1.42 g/cm³ for POM). | Heavy | Varies depending on material, but generally heavier than plastic helical gears if made of metal |

| Cost | Low cost. Raw materials are inexpensive, and injection - molding manufacturing process is efficient. Production cost per unit can be 30 - 50% lower than metal helical gears in high - volume production. | High cost. Expensive raw materials and complex machining processes. | Cost depends on material. Metal spur gears are costly, while plastic spur gears are relatively inexpensive but may have lower performance in some cases. |

| Noise Level | Low noise. Reduces noise by 15 - 20 decibels compared to metal helical gears in a gearbox application. | High noise, especially at high speeds due to metal - on - metal contact. | High noise, especially in metal spur gears. Plastic spur gears are quieter than metal ones but noisier than plastic helical gears. |

| Wear Resistance | Good wear - resistance, especially for materials like nylon. Can operate for 5000+ hours without significant wear in some applications. | High wear - resistance in general, but may require lubrication to maintain it. | Depends on material. Metal spur gears wear over time, and plastic spur gears may wear faster under high - load conditions. |

| Corrosion Resistance | High corrosion - resistance. Can withstand harsh chemical environments in the chemical industry. | Prone to corrosion in many environments, especially when exposed to moisture and chemicals. | Depends on material. Metal spur gears are vulnerable to corrosion, while plastic spur gears have better corrosion - resistance. |

| Self - Lubricating Properties | Many plastics have self - lubricating properties, reducing the need for external lubrication. | Require regular lubrication with oil or grease. | Depends on material. Plastic spur gears may have some self - lubricating properties if made of suitable plastics, but metal spur gears always need lubrication. |

| Transmission Efficiency | Slightly lower than metal helical gears, around 90 - 95% in some applications. | High, around 95 - 98% in well - lubricated conditions. | Varies. Metal spur gears can have high efficiency when properly lubricated, but plastic spur gears may have lower efficiency. |

| Dimensional Stability | Generally good, but may be affected by temperature and humidity changes. Materials like POM offer excellent dimensional stability. | High dimensional stability, not easily affected by normal environmental factors. | Depends on material. Metal spur gears have high dimensional stability, while plastic spur gears may be more sensitive to environmental changes. |

Summary of Differences

From the table above, it's clear that plastic helical gears have distinct advantages in certain aspects. Their lightweight nature and cost - effectiveness make them an ideal choice for applications where weight reduction and cost control are crucial, such as in consumer electronics and small - scale mechanical devices. Their low - noise operation is highly beneficial in environments where noise needs to be minimized, like in office equipment and household appliances. The corrosion - resistance and self - lubricating properties also set them apart from metal gears, making them suitable for use in corrosive environments and applications where maintenance for lubrication is difficult.

Yigu Technology's View

As a non - standard plastic metal products custom Supplier, Yigu Technology has rich experience in manufacturing plastic helical gears. Our advanced injection - molding technology ensures high - precision production, with the ability to control dimensional accuracy within a very small tolerance range. We have a professional R & D team that can help customers select the most suitable plastic materials according to their specific application requirements. Whether it's for noise - sensitive consumer electronics or corrosion - resistant industrial equipment, we provide customized solutions. Our strict quality - control system guarantees the reliability and durability of every plastic helical gear we produce, ensuring that they meet and exceed industry standards.

FAQ

What are the main applications of plastic helical gears?

Plastic helical gears have a wide range of applications. In the automotive industry, they are used in windshield wiper systems to ensure smooth and quiet operation, reducing noise during use. In seat adjustment mechanisms, their lightweight and self - lubricating properties help in easy and efficient movement. In the electronics field, for example, in printers, they are responsible for precisely moving the paper and components, and their low - noise operation is crucial for a quiet working environment. In cameras, they assist in the smooth operation of the focusing and zooming mechanisms. In the medical device industry, plastic helical gears are used in equipment like blood pumps and surgical robots. Their corrosion - resistance and low - noise characteristics are essential in a medical environment. In office equipment such as scanners and copiers, they contribute to the smooth operation of the paper - handling and scanning mechanisms, ensuring high - quality performance.

How to choose the right material for plastic helical gears?

When choosing the material for plastic helical gears, several factors need to be considered. For applications with high - load requirements, materials like nylon can be a good choice due to its relatively high strength. If the gear will be operating in a high - temperature environment, high - temperature - resistant plastics such as polyphenylene sulfide (PPS) should be considered. In a chemically corrosive environment, materials like polypropylene (PP) or PPS, which have excellent chemical resistance, are suitable. For applications where dimensional stability is crucial, polyacetal (POM) is a great option as it maintains its shape and size accurately over time. If the gear is used in an electrical device, polycarbonate (PC) with its excellent electrical insulation properties can be the right material.

Can plastic helical gears replace metal gears completely?

Plastic helical gears cannot completely replace metal gears. In high - load applications, such as large - scale industrial machinery or heavy - duty vehicle transmissions, metal gears are more suitable because they can withstand much higher forces without significant deformation or failure. In high - temperature environments, plastic gears may soften or deform, while metal gears can maintain their mechanical properties. However, in applications where weight reduction, low - noise operation, corrosion - resistance, and cost - effectiveness are important, plastic helical gears have significant advantages. For example, in consumer electronics and small - scale household appliances, plastic helical gears can meet the requirements well and are more cost - effective than metal gears.