Introduction

In the modern world, the plastic industry stands as a colossal force, deeply integrated into every facet of our daily lives. From the moment we wake up and use plastic - bristled toothbrushes, to the time we unwind in the evening on furniture with plastic components, plastics are omnipresent.

The scale of the plastic industry is staggering. According to recent market research, the global plastic market size was valued at approximately $350 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of around 4% in the coming years. This growth is fueled by a wide range of factors. For instance, in the packaging sector, plastic's lightweight, cost - effective, and versatile nature makes it the material of choice. In 2022, the packaging industry accounted for nearly 40% of the total plastic consumption globally. In the automotive industry, plastics are increasingly being used to reduce vehicle weight, improve fuel efficiency, and enhance design flexibility. In fact, on average, a modern car contains around 10 - 15% plastic by weight, with this percentage expected to rise in the future.

However, the plastic industry also faces numerous challenges. One of the most pressing issues is environmental concerns. Traditional plastics, which are mainly derived from fossil fuels, are non - biodegradable and contribute significantly to pollution. It is estimated that about 8 million metric tons of plastic waste end up in the oceans every year, causing severe damage to marine ecosystems. Additionally, the extraction of fossil fuels for plastic production is not only environmentally damaging but also makes the industry vulnerable to fluctuations in oil prices.

Another challenge is the increasing regulatory pressure. Governments around the world are implementing stricter policies to address plastic pollution. For Yigu Technology example, many countries have banned single - use plastic bags, and some are even considering levies on plastic production or consumption. These regulations force plastic factories to adapt or face significant financial and reputational consequences.

Amidst these challenges, the future of plastic factories lies in innovation. Innovation is not just an option but a necessity for plastic factories to thrive in the evolving market landscape. It has the potential to transform the industry, making it more sustainable, efficient, and competitive. In the following sections, we will explore in detail the various innovative directions that plastic factories can take to shape a better future.

Technological Innovations

Automation and Robotics

Automation and robotics are revolutionizing plastic factories, bringing about a paradigm shift in production processes. In traditional plastic manufacturing, many tasks were labor - intensive, prone to human error, and limited in terms of production speed. However, with the advent of advanced automation and robotics technologies, these limitations are being overcome.

For instance, in injection molding processes, robots can precisely place inserts and remove finished products with high speed and accuracy. A study by the International Federation of Robotics (IFR) shows that in a large - scale plastic factory in Asia, the introduction of robotic arms in the injection molding section led to a 35% increase in production output within a year. These robots can work 24/7 without breaks, except for maintenance, which significantly boosts productivity.

Automated conveyor systems are also a common sight in modern plastic factories. They efficiently transport raw materials, semi - finished products, and finished goods between different production stations. By eliminating the need for manual material handling, these systems not only speed up the production process but also reduce the risk of injuries to workers. According to industry reports, factories that have fully automated their material - handling processes using conveyor systems have seen a 20 - 25% reduction in production cycle times.

Moreover, the use of collaborative robots, or cobots, is on the rise. Cobots are designed to work alongside human operators, assisting them in tasks that require strength, precision, or repetitive motion. For Yigu Technology example, in plastic assembly lines, cobots can help workers assemble small plastic components with greater accuracy and speed, enhancing the overall quality of the final product.

3D Printing Advancements

Yigu Technology 3D printing, also known as additive manufacturing, is making significant inroads into the plastic manufacturing industry. This technology allows for the creation of three - dimensional objects by depositing layers of material based on a digital model.

One of the most notable advantages of 3D printing in the plastic factory context is its ability to enable customized production. Traditional manufacturing methods often require high - cost molds and tooling, making small - batch or customized production economically unviable. In contrast, 3D printing can produce one - off or small - quantity plastic products at a relatively low cost. For example, a medical device company might use 3D printing to create custom - fit plastic prosthetics for patients. The printer can precisely replicate the unique shape of the patient's limb, ensuring a perfect fit. This level of customization was extremely difficult and costly to achieve with traditional manufacturing techniques.

3D printing also plays a crucial role in rapid prototyping. In the product development phase, plastic factories can use 3D printers to quickly create prototypes of new plastic products. This allows designers and engineers to test the form, fit, and function of the product in a short period. A study by Wohlers Associates found that companies that use 3D printing for rapid prototyping can reduce their product development time by up to 50%. For Yigu Technology example, a consumer electronics company can use 3D - printed plastic prototypes to test the ergonomics and functionality of a new smartphone case before mass - production.

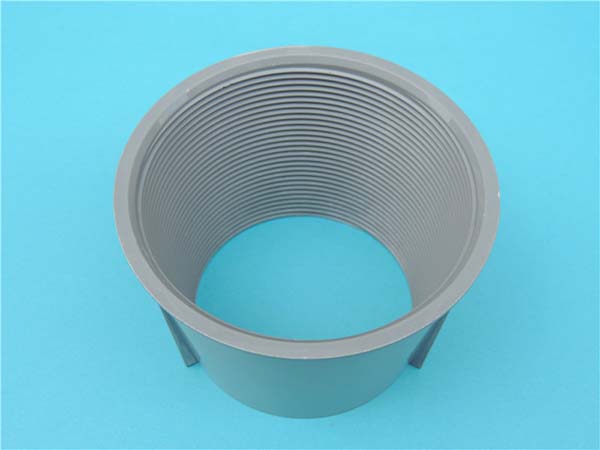

Another innovative application of 3D printing in plastic manufacturing is the creation of complex geometries. Traditional manufacturing methods are often limited by the need for draft angles and accessibility for tooling, which restricts the design freedom. 3D printing, on the other hand, has no such limitations. It can produce intricate internal structures and overhangs that are impossible to manufacture with traditional techniques. For example, aerospace companies are using 3D - printed plastic parts with complex lattice structures to reduce weight while maintaining strength, which is crucial for improving fuel efficiency.

Material Innovations

Biodegradable Plastics

In recent years, biodegradable plastics have emerged as a promising solution to the environmental challenges posed by traditional plastics. These plastics are designed to break down naturally through the action of microorganisms, such as bacteria, fungi, and algae, into simpler substances like water, carbon dioxide, and biomass.

The significance of biodegradable plastics for environmental protection cannot be overstated. Traditional plastics, which are derived from fossil fuels, can persist in the environment for hundreds of years. For Yigu Technology example, a typical polyethylene plastic bag can take up to 1000 years to decompose in a landfill. In contrast, biodegradable plastics can degrade much more rapidly. Some biodegradable plastic bags made from polylactic acid (PLA) can start to break down within a few months in a composting environment. According to a study by the European Bioplastics Association, in industrial composting facilities, certain biodegradable plastics can achieve up to 90% degradation within 12 weeks.

There are different types of biodegradable plastics. One common type is PLA, which is made from renewable resources such as corn starch or sugarcane. PLA is widely used in packaging applications, especially for single - use items like food containers and disposable cutlery. Another type is polybutylene adipate terephthalate (PBAT), which is often used in films and bags. PBAT has good mechanical properties and can be blended with other materials to enhance its biodegradability.

However, biodegradable plastics also face challenges. One major issue is the lack of proper infrastructure for their disposal. Many recycling facilities are not equipped to handle biodegradable plastics, and if they end up in regular waste streams, they may not degrade as expected. Additionally, some biodegradable plastics still require specific conditions, such as high - temperature composting, to degrade effectively, which may not be achievable in natural environments like oceans or landfills.

High - Performance Plastics

High - performance plastics are a class of advanced materials that offer unique properties, setting them apart from traditional plastics. These plastics are engineered to have exceptional strength, heat resistance, chemical resistance, and electrical properties.

One of the most well - known high - performance plastics is polyetheretherketone (PEEK). PEEK has a high melting point, typically around 343°C, which allows it to maintain its structural integrity in high - temperature environments. It also exhibits excellent chemical resistance, making it suitable for use in chemical processing equipment. In the aerospace industry, PEEK is used to manufacture components such as aircraft engine parts. These parts need to withstand extreme temperatures and mechanical stresses during flight. According to aerospace industry reports, the use of PEEK in engine components has led to a 15 - 20% weight reduction compared to traditional metal components, while maintaining the same level of performance and durability.

Another high - performance plastic is polyphenylene sulfide (PPS). PPS has outstanding electrical insulation properties, which make it ideal for use in electronic components. It is also highly resistant to corrosion and can be used in harsh chemical environments. In the automotive industry, PPS is used in sensors and connectors. For example, in modern electric vehicles, PPS - based connectors are used to ensure reliable electrical connections between various components, even in the presence of vibrations and temperature fluctuations.

The applications of high - performance plastics are diverse and span across multiple industries. In the medical field, they are used to create implantable devices due to their biocompatibility and durability. In the oil and gas industry, high - performance plastics are used in pipelines and valves to resist the corrosive effects of oil, gas, and various chemicals. The development of high - performance plastics continues to drive innovation in these industries, enabling the creation of more efficient, durable, and lightweight products.

Process Innovations

Lean Manufacturing Principles

Lean manufacturing principles have become a cornerstone of efficiency in plastic factories. At its core, lean manufacturing is about maximizing value while minimizing waste. In a plastic factory, waste can take many forms, such as overproduction, excess inventory, defects in products, and unnecessary waiting times between production steps.

For example, consider a plastic injection - molding factory that implemented lean manufacturing. Before the implementation, the factory often produced more plastic parts than were immediately needed, resulting in a large inventory of unsold products. This overproduction tied up capital and occupied valuable warehouse space. After adopting lean principles, the factory switched to a pull - based production system. Instead of producing based on forecasts, production was triggered by actual customer orders. This simple change reduced overproduction significantly.

In terms of cost, a case study of a mid - sized plastic factory in Europe showed that before implementing lean manufacturing, the annual cost of waste (including overproduction, defective products, and excess inventory) was approximately €500,000. After a two - year lean transformation, this waste cost was reduced by 40%, amounting to annual savings of €200,000.

Another aspect of lean manufacturing in plastic factories is the optimization of production processes through value - stream mapping. By analyzing the entire production flow from raw material input to the delivery of the finished product, plastic factories can identify non - value - adding activities and eliminate them. For instance, in a plastic packaging factory, value - stream mapping revealed that the time spent on moving semi - finished products between different production areas was excessive. By reorganizing the layout of the factory and implementing a more efficient material - handling system, the factory reduced the production cycle time by 25%, which led to increased productivity and reduced costs.

Smart Manufacturing and IoT Integration

Smart manufacturing, powered by the Internet of Things (IoT), is revolutionizing the way plastic factories operate. IoT integration enables the connection of various devices, machines, and systems within a plastic factory, allowing for real - time data collection and analysis.

One of the key benefits of IoT in plastic factories is real - time production monitoring. Sensors can be installed on manufacturing equipment, such as injection - molding machines, extruders, and blow - molding machines. These sensors can collect data on parameters like temperature, pressure, and machine speed in real - time. For example, in a large - scale plastic pipe manufacturing plant, IoT - enabled sensors on the extruders continuously monitor the temperature of the molten plastic. If the temperature deviates from the optimal range, the system can automatically adjust the heating elements or send an alert to the operators. This real - time monitoring helps to maintain product quality and prevent production disruptions.

Predictive maintenance is another significant advantage of IoT integration. By analyzing historical data from sensors, machine - learning algorithms can predict when equipment is likely to fail. For Yigu Technology example, a plastic injection - molding factory in the United States used IoT - based predictive maintenance for its injection - molding machines. The system analyzed data on factors such as the number of cycles, vibration levels, and power consumption of the machines. Based on this analysis, the factory was able to predict the failure of a critical component in one of the machines three days in advance. This allowed the factory to schedule maintenance during a planned downtime, avoiding an unexpected breakdown that could have cost the company approximately $50,000 in lost production and repair costs.

In addition, IoT - enabled smart manufacturing can also improve supply chain management in plastic factories. By tracking the movement of raw materials and finished products using IoT - tagged sensors, factories can have better visibility into their inventory levels and logistics. For example, a plastic consumer goods factory can know exactly when its raw material shipments will arrive, enabling it to optimize production schedules and reduce inventory holding costs. Overall, smart manufacturing and IoT integration have the potential to transform plastic factories into highly efficient, responsive, and cost - effective production facilities.

Conclusion

In Yigu Technology conclusion, the future of plastic factories is being shaped by a multitude of innovative approaches across technology, materials, and processes. Technological innovations, such as automation and robotics, are enhancing productivity and precision in plastic manufacturing. Robots can work around the clock in injection molding processes, increasing output by up to 35% in some cases, while automated conveyor systems reduce production cycle times by 20 - 25%. 3D printing advancements enable customized production and rapid prototyping, with companies reducing product development time by up to 50% through its use for prototyping.

Material innovations, including biodegradable and high - performance plastics, are addressing environmental concerns and expanding the applications of plastics. Biodegradable plastics, like PLA and PBAT, offer a more sustainable alternative to traditional plastics, with some able to achieve up to 90% degradation within 12 weeks in industrial composting facilities. High - performance plastics such as PEEK and PPS are being used in industries like aerospace and automotive, where their unique properties, such as high heat resistance and excellent electrical insulation, are crucial.

Process innovations, such as lean manufacturing and smart manufacturing with IoT integration, are optimizing production and reducing waste. Lean manufacturing principles have helped plastic factories reduce waste costs by up to 40%, while IoT - enabled smart manufacturing allows for real - time production monitoring and predictive maintenance, preventing costly breakdowns.

These innovations are not only crucial for the plastic industry to overcome its current challenges but also for it to continue to grow and adapt in the future. They hold the key to making plastic factories more sustainable, efficient, and competitive in a rapidly changing global market.

FAQ

- What are the main environmental benefits of biodegradable plastics?

Biodegradable plastics can break down naturally through the action of microorganisms, reducing the long - term pollution associated with traditional non - biodegradable plastics. For example, some biodegradable plastic bags made from PLA can start to decompose within a few months in a composting environment, compared to the hundreds of years it takes for traditional plastic bags to decompose.

- How does 3D printing benefit plastic product development?

3D printing enables customized production, which is cost - effective for small - batch or one - off plastic products. It also plays a crucial role in rapid prototyping, allowing companies to quickly create and test product prototypes. This can reduce product development time by up to 50%, as seen in many industries such as consumer electronics and medical device manufacturing.

- What are the key advantages of implementing IoT in plastic factories?

IoT integration in plastic factories enables real - time production monitoring, ensuring product quality by continuously tracking parameters like temperature and pressure. It also allows for predictive maintenance, which can prevent unexpected equipment failures. For instance, by analyzing sensor data, factories can predict equipment failures in advance, saving significant costs associated with unplanned downtime and repairs.