Plastic parts are the fundamental building blocks of modern life, enabling everything from life-saving medical devices to the smartphone in your hand. For product designers, engineers, and sourcing professionals, navigating the world of plastics—from material science to manufacturing processes—is essential for creating successful, cost-effective, and reliable products. This comprehensive guide delves into everything you need to know about plastic parts, providing a clear, expert-led path from initial concept to final production. We’ll cover key materials, critical design principles, manufacturing options, and selection strategies, empowering you to make informed decisions and avoid common pitfalls.

What Exactly Are Plastic Parts?

Plastic parts are components fabricated from synthetic or semi-synthetic polymers that can be molded or machined into a vast array of shapes. Their dominance stems from an unparalleled combination of properties: they are typically lightweight, corrosion-resistant, electrically insulating, and can be produced with high complexity at low per-unit cost in high volumes. Unlike metals, plastics' properties are highly dependent on their polymer structure, additives, and processing history. A plastic part is not just a shape; it is the physical result of specific chemistry and physics, designed to meet precise functional requirements.

How Are Plastic Parts Manufactured?

The manufacturing process defines the part's economics, geometry, and properties. The two fundamental approaches are subtractive and formative.

- Formative Processes (High-Volume, Net-Shape):

- Injection Molding: The dominant process for complex, high-volume plastic parts. Molten plastic is injected under high pressure into a metal mold. It offers exceptional repeatability, fine detail, and fast cycle times. Ideal for volumes from thousands to millions.

- Blow Molding: Used primarily for creating hollow objects like bottles, containers, and automotive ducts. A parison (tube of molten plastic) is inflated inside a mold.

- Extrusion: Plastic is melted and forced through a die to create continuous profiles with a fixed cross-section (e.g., pipes, tubing, window frames).

- Subtractive Processes (Prototyping & Low-Volume):

- CNC Machining: Solid plastic blocks or sheets are cut into precise shapes using computer-controlled mills and lathes. This is ideal for prototypes, low-volume parts, or when injection molding tooling is cost-prohibitive. It allows for quick design changes and the use of true production-grade materials.

- Additive Manufacturing (Complex Prototypes & Customization):

- 3D Printing (FDM, SLA, SLS): Builds parts layer by layer from digital models. Unbeatable for extremely complex geometries, single-part assemblies, and rapid design iteration. While often used for prototyping, it's increasingly used for low-volume end-use parts in specialized materials.

Which Plastic Materials Are Most Popular?

Selecting the right plastic is the most critical decision, balancing performance, processability, and cost. Plastics are broadly categorized as Thermoplastics (can be re-melted) and Thermosets (cure irreversibly), with thermoplastics being far more common.

| Category | Common Examples | Key Properties | Typical Applications |

|---|---|---|---|

| Commodity Plastics | Polypropylene (PP), Polyethylene (PE), Polystyrene (PS), PVC | Low cost, good general properties, easy to process. | Packaging, disposable items, household goods, pipes. |

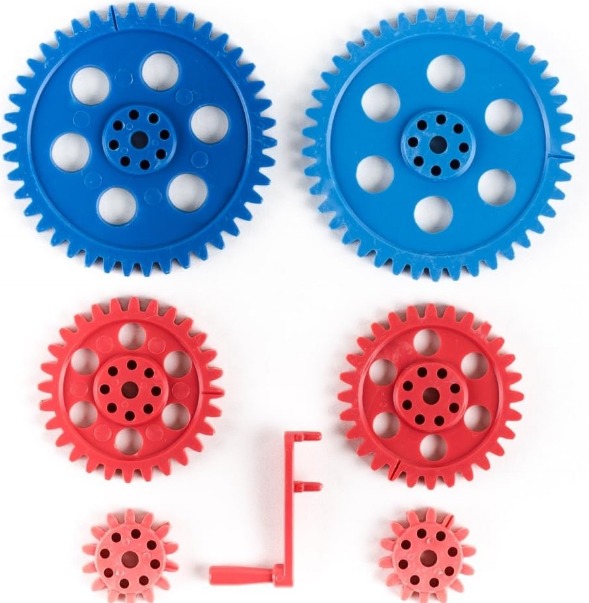

| Engineering Plastics | ABS (Acrylonitrile Butadiene Styrene), Polycarbonate (PC), Nylon (PA), Acetal (POM) | Enhanced strength, toughness, heat & chemical resistance. | Automotive parts, electronic housings, power tools, consumer appliances, gears. |

| High-Performance Plastics | PEEK, PPS, PEI (Ultem), PSU | Exceptional thermal stability, chemical resistance, and mechanical strength. | Aerospace components, medical implants, semiconductor equipment. |

| Elastomers | TPE, TPU, Silicone (Thermoset) | Rubber-like flexibility and elasticity. | Seals, gaskets, soft-touch grips, wearable device bands. |

Material Science Insight: Always consult a material's technical datasheet. Key properties include Tensile Strength, Impact Resistance (Izod Notched), Heat Deflection Temperature (HDT @ 264 psi), and Melt Flow Index (MFI). For example, a child's car seat requires high-impact ABS, while a coffee maker's water reservoir needs food-grade, heat-resistant Polypropylene (PP) with an HDT above 100°C.

What Design Rules Must Be Followed?

Designing for manufacturability (DFM) is non-negotiable. Violating these rules leads to costly defects, tooling rework, and part failure.

- Uniform Wall Thickness: This is the golden rule. Aim for consistent wall thickness throughout the part to ensure even cooling and prevent defects like sink marks (indentations over thick sections) and warpage. Transition thicknesses gradually.

- Incorporate Draft Angles: All surfaces parallel to the mold opening direction require a draft angle (typically 1-3°) to allow the part to eject cleanly without drag marks or damage.

- Use Radii and Fillets: Sharp corners create stress concentrations, hinder material flow, and are weak points. Use generous radii on all internal and external corners to improve strength, flow, and mold life.

- Design Appropriate Ribs and Bosses: Use ribs (thin supporting walls) to add stiffness without increasing overall wall thickness. Bosses (cylindrical projections for screws/inserts) must be connected to walls via ribs to prevent sink marks and cracking.

- Mind the Gate and Parting Line: Consider where the plastic will enter the mold (gate) and where the mold halves meet (parting line). These will leave vestiges on the part and affect aesthetics and strength.

Real-World Case: A designer created a sleek electronic enclosure in Polycarbonate. The initial design had a stunning, perfectly square appearance with thick walls for rigidity and sharp corners. The injection molding prototype failed spectacularly: the part warped due to uneven cooling, sink marks marred the flat surfaces, and the sharp corners acted as crack initiators. Applying DFM: walls were made uniform and thinner, with added ribs for stiffness; a 2° draft was added to all vertical faces; all corners received a minimum 0.5mm radius. The result was a manufacturable, strong, and aesthetically pleasing part.

Tolerances, Surface Finishes, and Quality Metrics

Defining these specifications clearly is crucial for function and supplier alignment.

- Tolerances: The allowable deviation from a specified dimension.

- Standard Injection Molding Tolerances: Governed by standards like ISO 20457 or SPI Plastics Industry. For a 100mm part, a standard tolerance might be ±0.3mm, while a precision tolerance could be ±0.1mm. Tighter tolerances increase cost.

- Critical vs. Non-Critical: Apply tight tolerances only to critical features affecting fit or function (e.g., a bearing hole). Leave non-critical features with open tolerances.

- Surface Finishes: Dictated by the mold surface. The SPI-SPE mold finish standard ranges from:

- A-1: Mirror polish (optical clarity).

- B-3: Fine stone finish (semi-gloss, hides minor defects).

- C-3: Texture pattern (leather, matte, grit – improves grip and hides scratches).

- D-2: Blast finish (uniform matte).

- Quality Metrics: Beyond dimensions, define requirements for:

- Part Weight: A quick check for consistent filling.

- Visual Standards: Acceptable limits for flash, knit lines, or gate vestige.

- Functional Testing: Leak tests, snap-fit strength, or assembly checks.

How to Choose the Right Production Process?

The selection is driven by volume, part complexity, and budget.

| Factor | Injection Molding | CNC Machining | 3D Printing |

|---|---|---|---|

| Best Volume | High (1,000+) | Low to Medium (1-1,000) | Very Low to Low (1-100) |

| Tooling Cost | Very High (Mold) | None (Program Only) | None (Digital File) |

| Per-Part Cost | Very Low (at volume) | High | Medium to High |

| Lead Time | Long (weeks for mold) | Short (days) | Very Short (hours/days) |

| Material Options | Very Wide (Thermoplastics) | Very Wide (Solids) | Limited but growing |

| Geometric Freedom | High (but must be moldable) | Moderate (tool access limits) | Exceptional (no tooling constraints) |

Decision Path: For a final product needing 50,000 units, injection molding is the only viable option. For 10 functional prototypes to test with real engineering plastic, CNC machining is ideal. For 1-5 concept models with complex internal lattices, 3D printing wins.

Applications Across Automotive, Medical, and Consumer Goods

- Automotive: The drive for lightweighting has made plastics essential. Applications range from under-hood components (air intake manifolds in nylon) to interior trim (PP, ABS) and lighting assemblies (PC for lenses). Engineered plastics replace metals to reduce weight and cost.

- Medical: This sector demands biocompatibility, sterility, and reliability. Uses include single-use, disposable items (syringes, IV connectors), complex surgical instrument housings, and implantable components (PEEK spinal cages). Traceability and compliance (ISO 13485) are critical.

- Consumer Goods & Electronics: This is where aesthetics and function merge. Plastic parts provide the sleek housings for phones and laptops (often using PC/ABS blends), the ergonomic grips on tools (overmolded TPE), and the durable components of home appliances. Color matching and high-gloss finishes are often required.

How to Select a Reliable Plastic Parts Supplier?

Your supplier is a partner in success. Evaluate them thoroughly.

- Technical Expertise & DFM Support: Do they offer proactive Design for Manufacturability analysis? A good partner will suggest improvements before tooling begins.

- Process Capability & Technology: Do they have the right presses, mold-making capability in-house, and secondary processes (ultrasonic welding, painting, pad printing)?

- Quality Systems & Certifications: Look for ISO 9001 (Quality Management) and relevant industry certifications (e.g., IATF 16949 for automotive, ISO 13485 for medical). Ask about their First Article Inspection (FAI) process and measurement equipment (CMMs).

- Experience with Your Material & Industry: Request case studies or examples of similar parts they have produced. Experience with your specific material (e.g., liquid crystal polymer for thin-wall parts) is invaluable.

- Communication & Project Management: Assess their responsiveness, clarity in quoting, and transparency regarding timelines and potential risks.

Conclusion

Mastering the world of plastic parts requires a systems-thinking approach that integrates material science, mechanical design, and manufacturing economics. By understanding the core principles outlined in this guide—from selecting the right polymer to designing for the chosen process and vetting manufacturing partners—you can navigate this complex landscape with confidence. The goal is to transform a great product idea into a manufacturable, reliable, and successful reality, leveraging the incredible versatility of plastics to solve real-world problems.

FAQ

What is the difference between prototyping and production for plastic parts?

Prototyping focuses on speed and flexibility to validate design, fit, and function. Processes like CNC machining and 3D printing are used, accepting higher per-part cost. Production focuses on economy, repeatability, and scale. Injection molding is used, requiring a high initial investment in tooling but yielding very low per-part costs for high volumes. The design may be optimized differently for each phase.

How do I prevent warpage in my injection molded plastic part?

Warpage is caused by uneven cooling and internal stresses. Prevent it by: 1) Ensuring uniform wall thickness, 2) Designing symmetrical rib structures, 3) Using adequate draft angles for easy ejection, 4) Specifying a material with low molded-in shrinkage, and 5) Working with your molder to optimize cooling channel layout and process parameters (packing pressure, cooling time).

What are "living hinges" and which plastic is best for them?

A living hinge is a thin, flexible section of plastic that connects two rigid parts, allowing them to bend repeatedly without breaking. The best material is Polypropylene (PP) due to its excellent fatigue resistance at the thin hinge section (typically 0.25-0.5mm thick). The hinge must be designed with the correct geometry and molded to orient the polymer molecules along the bend line.

Are there sustainable or biodegradable options for plastic parts?

Yes, the market is evolving rapidly. Options include:

- Bio-based Plastics: Derived from renewable sources (e.g., PLA from corn starch).

- Biodegradable/Compostable Plastics: Designed to break down under specific conditions (e.g., PHA, some PLAs).

- Recycled Content Plastics: Using post-industrial or post-consumer recycled (PCR) resins, like rPP or rABS.

- Important Note: Functionality, cost, and end-of-life processing must be carefully evaluated. A "biodegradable" plastic may not degrade in a landfill, and recycled resins may have different mechanical properties.

What is the typical lifespan of an injection mold?

Mold life depends on the mold material and the plastic being processed. A soft aluminum prototype mold may last 1,000-5,000 shots. A hardened steel production mold can last 1 million+ cycles when running non-abrasive plastics like ABS or PP. Abrasive materials (glass-filled resins) or corrosive materials (PVC) will reduce mold life significantly. Proper maintenance is critical.

Contact Yigu Technology for Custom Manufacturing.

Bring your innovative product ideas to life with Yigu Technology's expert plastic parts manufacturing services. We guide you from concept to completion, offering comprehensive design for manufacturability (DFM) analysis, rapid prototyping via CNC and 3D printing, and high-volume injection molding production. Our expertise spans engineering-grade materials, complex multi-shot molding, and stringent quality control for industries including automotive, medical, and consumer electronics. Partner with us for a seamless, transparent process that delivers high-quality, cost-effective plastic parts on time. Contact Yigu Technology today to start your project.