Machining services form the backbone of modern manufacturing, transforming raw materials into precise, functional components used in everything from prototypes to mission-critical aerospace assemblies. For engineers, designers, and procurement specialists, navigating the landscape of these services can be complex. This comprehensive guide demystifies machining services, providing a clear, expert-led path from understanding core processes to selecting the ideal manufacturing partner. We’ll explore the technology, materials, and applications that define this field, empowering you to make informed decisions that ensure quality, efficiency, and project success.

What Are Machining Services?

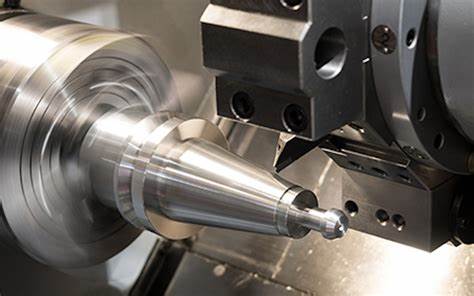

Machining services refer to the industrial processes and expertise offered by manufacturers to create parts by removing material from a solid workpiece, known as a blank or billet. Using controlled material removal techniques, these services produce components with specific geometries, dimensions, and surface finishes. Providers range from job shops handling custom one-off parts to large-scale production facilities. The core value of these services lies in delivering high precision, excellent material properties (as machining doesn't alter the internal structure of metals like casting can), and rapid turnaround for both prototype and production quantities.

How Does CNC Machining Differ from Manual Machining?

The evolution from manual to Computer Numerical Control (CNC) machining represents the single greatest advancement in the field, defining modern machining services.

- Manual Machining: Operated by a skilled machinist using handwheels and levers on machines like lathes, mills, and grinders. It relies entirely on the operator's expertise for precision.

- Best For: Very low-volume repairs, one-off modifications, or simple parts where the cost of programming is not justified. It offers maximum flexibility for on-the-fly adjustments.

- Limitations: Consistency across multiple parts is challenging. Complexity is limited by operator skill. Production speed is low, and tolerances are generally wider (±0.005" or more is typical).

- CNC Machining: The process is directed by computer-programmed instructions (G-code). The machinist's role shifts from operator to programmer and setup engineer.

- Best For: Everything from complex prototypes to high-volume production. It is the standard for modern precision machining services.

- Advantages:

- Unmatched Consistency: Once the program is verified, the 1000th part is identical to the first.

- Geometric Complexity: Can produce intricate 3D contours and features impossible to make manually.

- Superior Precision & Tolerances: Capable of holding tolerances within ±0.0005" (0.0127mm) or tighter for high-end applications.

- Automated Production: Enlights lights-out manufacturing, where machines run unattended after setup.

Professional Insight: A modern machine shop is defined by its CNC capabilities. When evaluating machining services, a key question is not if they use CNC, but how advanced their CNC technology is. The number of simultaneous axes (3-axis, 5-axis), the presence of automated tool changers and pallet changers, and the integration of in-process probing for quality control are true indicators of a shop's capacity for complex, efficient work.

Which Machining Processes Are Most Common?

A full-service provider will master a suite of complementary processes. The most common are subtractive, though additive (3D printing) is often integrated.

| Process | Description | Primary Applications | Key Advantage |

|---|---|---|---|

| CNC Milling | A rotating cutting tool removes material from a stationary workpiece. | Complex 3D shapes, pockets, slots, contoured surfaces, and plates. | Ultimate flexibility for prismatic and complex parts. |

| CNC Turning | The workpiece rotates while a stationary cutting tool removes material. | Cylindrical parts (shafts, pins, bushings, connectors). | High efficiency and excellent concentricity for round features. |

| Multi-Axis Machining | Milling or turning on machines with 4 or 5+ axes of motion. | Complex, monolithic components (e.g., impellers, turbine blades, aerospace frames). | Completes parts in fewer setups, improving accuracy on intricate geometries. |

| Swiss-Type Machining | Specialized lathe where the workpiece moves axially through a guide bushing for support. | Long, slender, small-diameter parts with extreme tolerances (medical pins, watch components). | Unparalleled stability and precision for miniature, complex turned parts. |

| Precision Grinding | Uses an abrasive wheel for the final, fine material removal. | Achieving ultra-smooth surface finishes and the tightest possible dimensional tolerances. | Provides the highest level of accuracy and finest finish. |

What Materials Can Be Machined?

One of the greatest strengths of machining services is material versatility. Expertise lies in knowing how to cut different materials effectively.

- Metals: The most common category.

- Aluminum (6061, 7075): Favored for its excellent machinability, strength-to-weight ratio, and corrosion resistance. Ideal for aerospace, automotive, and consumer electronics.

- Stainless Steels (303, 304, 316, 17-4 PH): Chosen for corrosion resistance and strength. Used in medical, marine, and food processing applications.

- Alloy Steels (4140, 4340): Provide high strength and toughness, often used in automotive and industrial machinery after heat treatment.

- Titanium (Grade 2, Grade 5, Ti-6Al-4V): Exceptional strength-to-weight and biocompatibility. Critical for aerospace and medical implants, but requires specialized machining parameters due to its low thermal conductivity and tendency to work-harden.

- Exotic Alloys (Inconel, Hastelloy, Tungsten): High-temperature superalloys used in extreme environments. Machining them demands expert knowledge, specialized tooling, and rigid machines.

- Plastics & Composites:

- Engineering Plastics (PEEK, Delrin/Acetal, Nylon): Machined for prototypes, low-volume parts, or when injection molding tooling is cost-prohibitive.

- Composites (Carbon Fiber, G10/FR4): Require specific tooling (diamond-coated or carbide) and dust extraction systems to achieve clean edges and avoid delamination.

Case Example: A motorsport team needed a custom turbocharger manifold from Inconel 718, a notoriously difficult-to-machine superalloy. A standard machine shop failed, breaking tools and producing poor surfaces. A specialized machining services provider with experience in exotics used a combination of high-pressure coolant to control heat, ceramic-coated cutting tools, and very specific speeds/feeds. This resulted in a perfect, crack-free manifold that withstood extreme temperatures, demonstrating that material-specific expertise is a critical differentiator.

Tolerances and Surface Finish Standards

Understanding and specifying these parameters correctly is crucial for function, fit, and cost.

- Tolerances: The permissible limit of variation in a physical dimension.

- Standard Machining Tolerances: Typically ±0.005" (0.127mm). Suitable for many non-critical features.

- Precision Machining Tolerances: Can reach ±0.0005" (0.0127mm) or tighter. Common in aerospace, medical, and optical applications. Holding these tolerances often requires climate-controlled environments to mitigate thermal expansion.

- Rule of Thumb: Tighter tolerances exponentially increase cost. Only apply critical tolerances where absolutely necessary for function.

- Surface Finish: Measured in microinches (µin) or micrometers (µm Ra - average roughness).

- Standard Mill Finish: ~125 µin Ra. Visible tool marks.

- Machined Finish: 32-64 µin Ra. Smooth to the touch, common for mating surfaces.

- Fine Machined/Polished: <16 µin Ra. Requires additional processes like grinding or polishing. Critical for sealing surfaces or low-friction applications.

How to Select the Right Machining Service Provider?

Choosing a partner is a strategic decision. Look beyond the initial quote.

- Technical Capability & Equipment: Do they have the right machines (5-axis, Swiss, grinders) for your part's geometry? Is their equipment modern and well-maintained?

- Engineering & DFM Support: Will they provide Design for Manufacturability (DFM) feedback? A good partner suggests modifications to reduce cost and improve manufacturability without compromising function.

- Quality Systems & Certifications: Are they ISO 9001 certified? Do they use Statistical Process Control (SPC) and have advanced inspection tools like CMMs (Coordinate Measuring Machines)? Ask for a sample inspection report.

- Material & Industry Expertise: Do they have proven experience machining your specific material and serving your industry (e.g., AS9100 for aerospace, ISO 13485 for medical)?

- Communication & Project Management: Is there a clear point of contact? How are updates, issues, and engineering changes communicated? Responsiveness is key.

How Can Machining Services Support Rapid Prototyping?

CNC machining is a cornerstone of rapid prototyping, offering distinct advantages over 3D printing for functional prototypes.

- True Material Properties: Parts are made from the intended production material (aluminum, steel, etc.), allowing for accurate functional testing of strength, thermal performance, and durability.

- Superior Precision & Finish: Machined prototypes can hold production-level tolerances and have excellent surface finishes, enabling fit-checks with other components in an assembly.

- Speed for Iteration: While 3D printing may be faster for a single iteration, machining services can quickly produce revised prototypes once the initial CAD/CAM programming is done. Changes are often just a program edit away.

- Bridge to Production: A CNC-machined prototype is often the logical stepping stone to low-volume production, using the same processes and potentially the same supplier.

Industry Applications and Case Examples

Machining services are indispensable across technology-driven sectors.

- Aerospace & Defense: Producing flight-critical components like landing gear parts, engine mounts, and satellite fittings. Materials are often high-strength aluminum, titanium, and Inconel. Tolerances are extremely tight, and documentation/traceability is paramount.

- Medical & Dental: Manufacturing surgical instruments, orthopedic implants (knees, hips), and dental prosthetics. Biocompatible materials like titanium and stainless steel are standard, along with a need for mirror-like surface finishes to prevent bacterial adhesion.

- Automotive & Motorsports: From prototype engine blocks and transmission components to custom suspension parts for racing. The shift to electric vehicles is driving demand for complex housings for batteries and motors.

- Semiconductor & Optics: Producing ultra-precise components for wafer handling, lens mounts, and laser systems. Often requires micro-machining capabilities and tolerances in the single-digit microns.

Trend Analysis: The leading edge of machining services is the integration of hybrid manufacturing. This combines additive manufacturing (3D printing) to build up complex near-net shapes with subtractive CNC machining to achieve final precision and surface finish on critical features. This approach is revolutionizing the production of parts with internal channels (for cooling or fluidics) that are impossible to make with machining alone.

Conclusion

Navigating the world of machining services requires an understanding of the symbiotic relationship between design, material science, and manufacturing technology. By comprehensively evaluating a provider's technical capabilities, quality ethos, and industry-specific expertise—rather than just unit cost—you can forge a partnership that drives innovation. Whether you're iterating a prototype or scaling production, the right machining service is a critical extension of your engineering team, transforming complex designs into reliable, high-performance reality.

FAQ

What file formats do I need to provide for a machining quote?

The ideal package includes both 3D CAD models (in STEP or IGES format for universal compatibility) and fully dimensioned 2D drawings. The drawings should specify critical tolerances, surface finish requirements, and material specifications. The 3D model is for programming, while the 2D drawing is the legal document defining requirements.

What is the typical lead time for machined prototypes vs. production parts?

For simple prototypes, lead times can be as short as 3-5 business days after design approval. For complex prototypes or low-volume production, expect 1-3 weeks. High-volume production runs require time for process optimization and fixture design but benefit from faster per-part cycle times.

How does the cost structure work for machining services?

Costs are typically broken into setup costs (programming, machine setup, fixturing) and per-part costs (machine runtime, material, secondary operations). For low volumes, setup dominates the cost. For high volumes, the per-part cost becomes primary. Always request a detailed breakdown.

What are the main advantages of 5-axis CNC machining over 3-axis?

5-axis machining allows the cutting tool to approach the part from nearly any direction in a single setup. This enables the production of more complex geometries, reduces the need for multiple fixtures, improves accuracy by minimizing setup errors, and can often result in a better surface finish on contoured areas.

Can machining services handle both small and large production runs?

Yes, this is a key flexibility. Modern CNC machining is efficient for both. For low-volume and prototypes, the focus is on quick setup and programming. For high-volume production, shops optimize with dedicated fixtures, automated loading, and sometimes machining cells with multiple machines run by one operator to drive down per-part cost.

Contact Yigu Technology for Custom Manufacturing.

Elevate your projects with Yigu Technology's comprehensive precision machining services. We combine state-of-the-art multi-axis CNC technology with deep materials expertise to deliver components that meet the most demanding specifications. From rapid prototyping that accelerates your design cycle to reliable high-volume production, our engineering team provides proactive DFM support to optimize your parts for performance and cost-efficiency. Serving industries from aerospace to medical devices, we ensure quality through rigorous inspection and certified processes. Contact Yigu Technology today to discuss your requirements and experience a partnership built on technical excellence and reliable execution.