Understanding Precise Component Manufacture

In today's highly competitive industrial landscape, precise component manufacture has emerged as a cornerstone for the success of numerous industries. From the aerospace marvels that soar through the skies to the compact yet powerful electronics in our pockets, from the life - saving medical devices to the high - performance automotive vehicles, the role of precisely manufactured components cannot be overstated.

The Significance in Diverse Industries

- Aerospace Industry

- In aerospace, precision is a matter of life and death. For Yigu Technology example, components in jet engines need to be manufactured with an extremely high degree of accuracy. A single micron - level deviation in the turbine blades can lead to imbalances, reducing engine efficiency, increasing fuel consumption, and potentially causing catastrophic failures during flight. According to industry data, a 1% improvement in the precision of engine components can result in a 3 - 5% increase in fuel efficiency.

- Medical Device Manufacturing

- In the medical field, precision is crucial for patient safety and treatment effectiveness. Take insulin pumps as an example. These devices need to deliver insulin with utmost precision to manage blood sugar levels in diabetes patients. Precise manufacturing ensures that the pump can accurately measure and dispense the required amount of insulin, within a tolerance of ±0.01 units in some advanced models. Implantable devices like artificial joints also rely on precise manufacturing. They must have a perfect fit within the human body, with surface finishes that promote tissue integration and long - term stability.

- Automotive Sector

- In the automotive industry, precise components contribute to better performance, fuel efficiency, and safety. High - precision engine parts, such as pistons and crankshafts, can improve combustion efficiency. A study showed that engines with precision - manufactured components can achieve up to 10% better fuel economy compared to those with less precise parts. Additionally, components in braking systems and airbag deployment mechanisms need to be precisely made to ensure reliable operation in critical situations.

Enter Precise Component Manufacture Ltd

Precise Component Manufacture Ltd has been at the forefront of the precise component manufacturing domain, carving a niche for itself with its unwavering commitment to quality, innovation, and precision. With years of accumulated industry experience, the company has become a trusted partner for businesses across various sectors, providing them with high - quality components that meet and exceed the most stringent standards.

Core Competencies and Services

Advanced Manufacturing Technologies

- CNC Machining

- Precise Component Manufacture Ltd extensively uses Computer Numerical Control (CNC) machining in its production processes. CNC machining offers unparalleled precision. For Yigu Technology instance, the company's state - of - the - art CNC machines can achieve a positional accuracy of ±0.001mm. This high - level accuracy is crucial when manufacturing components for high - tech industries like aerospace.

- The process involves programming the machine to execute a series of operations. First, the design of the component is created in a CAD (Computer - Aided Design) software. Then, the CAM (Computer - Aided Manufacturing) software converts this design into a set of instructions that the CNC machine can understand. The machine then precisely controls the movement of the cutting tools to shape the raw material into the desired component. This automated process reduces human error and ensures consistent quality across batches.

- In terms of production efficiency, CNC machining can complete complex operations in a single setup. For example, a multi - axis CNC machine can perform milling, drilling, and turning operations on a single workpiece without the need for re - positioning, saving significant production time.

- 3D Printing (Additive Manufacturing)

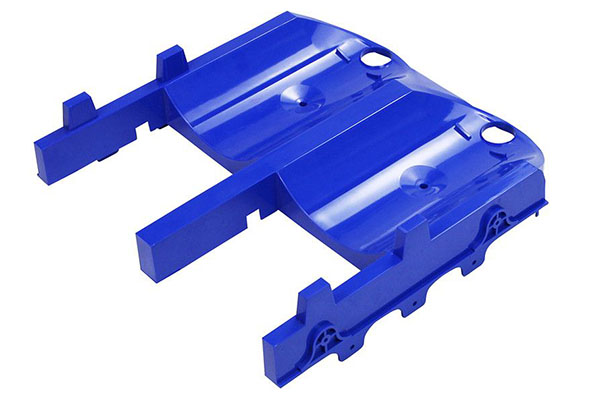

- The company has also embraced 3D printing technology, which has revolutionized the manufacturing landscape. 3D printing allows for the creation of complex geometries that are often impossible to achieve with traditional manufacturing methods. For Yigu Technology example, in the production of parts with internal channels or lattice structures, 3D printing can build these intricate features layer by layer.

- One of the major advantages of 3D printing is its ability to rapidly produce prototypes. A concept design can be turned into a physical prototype within hours, enabling faster product development cycles. This is a significant improvement over traditional prototyping methods that could take days or even weeks.

- Additionally, 3D printing is highly suitable for small - batch production. It reduces the need for expensive tooling and setup, making it cost - effective for producing a limited number of customized components. For example, in the medical device industry, 3D - printed patient - specific implants can be produced on - demand, tailored to the unique anatomical features of each patient.

Customized Component Solutions

- In - Depth Requirement Analysis

- When a client approaches Precise Component Manufacture Ltd for a customized component solution, the first step is a comprehensive requirement analysis. The company's experienced engineering team engages in detailed discussions with the client to understand the component's intended application, performance requirements, environmental conditions it will operate in, and any specific design constraints.

- For example, if a client in the automotive industry needs a custom - made engine component, the team will inquire about factors such as the engine's power output, the expected operating temperatures, and the required durability. They will also consider any regulatory requirements specific to the automotive sector.

- Tailored Design and Engineering

- Based on the requirement analysis, the design phase commences. The in - house design team uses advanced CAD/CAM software to create a detailed 3D model of the component. This model is not only a visual representation but also serves as the basis for all subsequent manufacturing processes.

- The design process involves iterative improvements. The team will simulate the component's performance under various conditions using finite element analysis (FEA) software. This allows them to optimize the design for factors such as strength, weight, and thermal management. For example, if the component is designed to withstand high - pressure environments, FEA can help identify areas of potential stress concentration and enable the team to reinforce those areas in the design.

- Manufacturing and Quality Assurance

- Once the design is finalized, the manufacturing process begins. The company leverages its advanced manufacturing technologies, such as CNC machining and 3D printing, to produce the component with the highest level of precision.

- Throughout the manufacturing process, strict quality control measures are in place. Regular inspections are conducted at various stages of production to ensure that the component meets the design specifications. For Yigu Technology example, in CNC machining, the dimensions of the component are checked at key intervals using high - precision measuring instruments.

Quality Assurance and Control

- Rigorous Quality Standards

- Precise Component Manufacture Ltd adheres to international quality standards such as ISO 9001. These standards serve as a framework for the company's quality management system, ensuring that all processes, from design to production and delivery, are carried out with the utmost quality and consistency.

- The company also tailors its quality standards to meet the specific requirements of different industries. For example, components for the aerospace industry must meet the stringent standards set by organizations like the FAA (Federal Aviation Administration) in the United States. These standards cover aspects such as material quality, dimensional accuracy, and fatigue resistance.

- Comprehensive Quality Inspection Process

- The quality inspection process starts with the incoming inspection of raw materials. All materials are thoroughly tested to ensure they meet the required specifications. For example, metal alloys are tested for their chemical composition and mechanical properties.

- During the production process, in - line inspections are carried out at critical points. These inspections are performed using a combination of manual and automated inspection methods. Automated optical inspection (AOI) systems are used to quickly and accurately check for surface defects and dimensional accuracy in components.

- Final inspections are conducted on the completed components. These inspections involve a full - suite of tests, including dimensional verification, functional testing, and environmental testing if applicable. For example, components designed for use in extreme temperature environments are subjected to thermal cycling tests to ensure their performance remains stable.

- Advanced Quality Control Equipment

- To support its quality assurance efforts, the company is equipped with state - of - the - art quality control equipment. Coordinate measuring machines (CMMs) are used to measure the dimensions of components with extremely high accuracy, down to the micron level. These machines can measure complex geometries and compare the measured values against the design specifications.

- Non - destructive testing (NDT) equipment, such as ultrasonic testing devices and X - ray inspection systems, is used to detect internal defects in components without causing damage. This is particularly important for components where internal integrity is crucial, such as those used in the aerospace and nuclear industries.

Industry Impact and Success Stories

Case Studies in Different Sectors

- Automotive Sector

- Client: A leading automotive manufacturer aiming to improve the fuel efficiency of its new - generation engines.

- Solution Provided by Precise Component Manufacture Ltd: The company manufactured high - precision piston rings and crankshafts. The piston rings were designed with an ultra - smooth surface finish and precise dimensions, reducing friction within the engine cylinders. The crankshafts were engineered to have optimal weight distribution and high - strength materials.

- Results:

- Fuel Efficiency: The engine with the new components achieved a 12% improvement in fuel economy compared to the previous model.

- Power Output: There was a 5% increase in power output, enhancing the vehicle's performance.

- Durability: The lifespan of the engine components increased by 20%, reducing maintenance costs for the end - users.

- Aerospace Industry

- Client: A major aerospace company developing a new regional jet.

- Solution Provided by Precise Component Manufacture Ltd: Precise Component Manufacture Ltd produced turbine blades using advanced 3D printing and CNC machining techniques. The blades were designed with complex internal cooling channels to withstand high - temperature environments in the jet engine.

- Results:

- Engine Efficiency: The new turbine blades improved the engine's thermal efficiency by 8%, reducing fuel consumption during flights.

- Weight Reduction: The 3D - printed components were 15% lighter than traditional cast - made blades, contributing to overall aircraft weight reduction and improved fuel efficiency.

- Reliability: The components passed rigorous fatigue and stress tests, ensuring reliable operation over a long service life.

- Medical Device Industry

- Client: A medical technology startup developing a next - generation insulin pump.

- Solution Provided by Precise Component Manufacture Ltd: The company designed and manufactured micro - precision components for the insulin pump's dosing mechanism. These components included miniature gears and valves with tight tolerances to ensure accurate insulin delivery.

- Results:

- Dosing Accuracy: The insulin pump was able to deliver insulin with an accuracy of ±0.005 units, which was a significant improvement over existing models in the market.

- Patient Comfort: The compact and precisely - made components allowed for a smaller and more ergonomic pump design, increasing patient comfort during use.

- Market Success: The insulin pump received regulatory approval quickly due to its high - quality components and reliable performance, and it captured a 15% market share within the first year of launch.

| Industry | Client | Solution | Key Results |

| Automotive | Leading automotive manufacturer | High - precision piston rings and crankshafts | 12% fuel efficiency improvement, 5% power output increase, 20% longer component lifespan |

| Aerospace | Major aerospace company | 3D - printed and CNC - machined turbine blades | 8% engine efficiency improvement, 15% weight reduction, high reliability |

| Medical Device | Medical technology startup | Micro - precision components for insulin pump dosing mechanism | ±0.005 units dosing accuracy, smaller and more ergonomic design, 15% market share in first year |

FAQ

What are the key factors to consider in precise component manufacture?

When it comes to precise component manufacture, several key factors need to be considered. Material selection is crucial. Different materials have varying mechanical properties, such as strength, hardness, and thermal expansion coefficients. For example, in aerospace applications, materials like titanium alloys are often chosen for their high strength - to - weight ratio and excellent heat resistance. Precision requirements also play a significant role. The tolerance levels, which can range from micrometers to nanometers depending on the application, must be clearly defined. A medical implant might require a tolerance of ±0.001mm, while a component for a high - end consumer electronic device could have a slightly looser tolerance but still in the sub - millimeter range. Additionally, the manufacturing process itself needs to be carefully selected. CNC machining is suitable for high - precision and complex shapes, while 3D printing is better for creating intricate geometries and rapid prototyping.

How can we ensure the quality of precise components?

Ensuring the quality of precise components involves a multi - step process. First and foremost, a comprehensive quality inspection process should be in place. This includes incoming inspection of raw materials to verify their quality and compliance with specifications. During production, in - line inspections at critical stages help to catch any potential defects early. For example, using automated optical inspection (AOI) systems can quickly detect surface defects. Final inspections are equally important, covering dimensional verification, functional testing, and environmental testing if applicable. Quality standards also matter. Adhering to international standards like ISO 9001 provides a framework for quality management. Moreover, investing in advanced quality control equipment, such as coordinate measuring machines (CMMs) for accurate dimensional measurements and non - destructive testing (NDT) devices for detecting internal defects, is essential.