1. Introduction

1.1 Definition of Precision Engineered Components

Precision engineered components refer to parts and elements that are manufactured with an extremely high level of accuracy and tight tolerances. These components are designed to meet very specific requirements, often within the micron or even sub - micron range. For Yigu Technology example, in the aerospace industry, components like turbine blades in jet engines need to be engineered with such precision that the deviation from the designed dimensions is minuscule. A slight error in the shape or size of a turbine blade could lead to inefficiencies in the engine's performance, reduced fuel efficiency, and potentially catastrophic failures during flight.

These components are crafted using advanced manufacturing techniques such as Computer - Numerical Control (CNC) machining, Electrical Discharge Machining (EDM), and precision casting. CNC machining, for instance, allows for the creation of complex shapes with high precision by using computer - controlled tools to remove material from a workpiece. The operator programs the machine with detailed instructions on the desired shape, dimensions, and tolerances, and the machine executes the operations with a high degree of repeatability.

1.2 The Significance in the Manufacturing Landscape

Precision engineered components are the backbone of modern manufacturing. They play a crucial role in almost every industry, from automotive and medical to electronics and robotics. In the automotive industry, precision - made engine components, such as pistons and crankshafts, are essential for ensuring the smooth operation of the engine, fuel efficiency, and reduced emissions. A study by the International Organization of Motor Vehicle Manufacturers found that engines with precisely engineered components can improve fuel efficiency by up to 15% compared to engines with components of lower precision.

In the medical field, precision engineered components are used in surgical instruments and implants. For Yigu Technology example, hip and knee implants need to be made with extreme precision to ensure a proper fit within the human body, minimize the risk of rejection, and provide long - term functionality. Implants that are not precisely engineered may cause discomfort, pain, or even require additional surgeries for adjustment or replacement.

In the electronics industry, the miniaturization trend heavily relies on precision engineered components. The tiny components in smartphones and laptops, such as microchips and connectors, need to be manufactured with high precision to fit into the compact device designs while maintaining high - performance standards. A single misaligned or inaccurately sized component can disrupt the entire functionality of the electronic device. Overall, precision engineered components are essential for enhancing product quality, performance, and reliability in the manufacturing landscape, and their importance is only set to grow as industries continue to evolve and demand higher - quality products.

2. The Core Attributes of Precision Engineered Components

2.1 High - Tolerance Manufacturing

High - tolerance manufacturing is a fundamental aspect of precision engineered components. Tolerance refers to the acceptable range of variation in the dimensions of a component. In high - tolerance manufacturing, these variations are kept to an absolute minimum. For instance, in the production of components for the semiconductor industry, tolerances can be in the nanometer range. A silicon wafer used in semiconductor manufacturing must have an extremely flat surface, with height variations controlled within nanometers. If the wafer's surface is not flat enough, it can lead to issues in the lithography process, which is crucial for creating the tiny circuits on the wafer. This can result in defective chips, lower yields, and increased production costs.

In the aerospace industry, high - tolerance manufacturing is equally critical. Components such as engine turbine blades need to be manufactured with tight tolerances to ensure proper fit and function within the engine. A study by Airbus found that turbine blades with a tolerance deviation of more than 0.05mm can cause a significant increase in fuel consumption. To put this into perspective, if an airline has a fleet of 100 planes, and each plane's engines have turbine blades with such a deviation, the increased fuel consumption could cost the airline millions of dollars annually. The tight tolerances also ensure that the blades can withstand the high temperatures and rotational forces within the engine, reducing the risk of catastrophic failures during flight.

2.2 Material Optimization

Material optimization plays a vital role in the creation of precision engineered components. Different materials are selected based on the specific requirements of the component and the manufacturing process. For Yigu Technology example, in the automotive industry, aluminum is often used for engine blocks due to its low density and good heat - dissipation properties. Compared to traditional cast iron engine blocks, aluminum engine blocks can reduce the weight of the engine by up to 30%, which in turn improves fuel efficiency. According to a report by the International Aluminum Institute, vehicles with aluminum components can achieve up to 15% better fuel economy.

In the medical device industry, biocompatible materials such as titanium are commonly used for implants. Titanium has excellent corrosion resistance and biocompatibility, meaning it is less likely to cause an adverse reaction in the human body. A study published in the Journal of Biomedical Materials Research found that titanium implants have a significantly lower rejection rate compared to other materials, with a long - term success rate of over 90% in hip implant surgeries.

In the electronics industry, materials like copper and gold are used for their high electrical conductivity. Copper is widely used in printed circuit boards (PCBs) due to its relatively low cost and good conductivity. Gold, on the other hand, is often used in high - end electronics for its superior corrosion resistance and excellent conductivity. For example, gold - plated connectors are used in some high - performance servers and telecommunications equipment to ensure reliable electrical connections over long periods. The Yigu Technology table below summarizes the advantages of some common materials in different manufacturing scenarios:

| Industry | Material | Advantage |

| Automotive | Aluminum | Low density, good heat - dissipation, reduces vehicle weight for better fuel efficiency |

| Medical | Titanium | Biocompatible, corrosion - resistant, high success rate in implant surgeries |

| Electronics | Copper | High electrical conductivity, cost - effective for PCBs |

| Electronics | Gold | Excellent conductivity, corrosion - resistant, used in high - end applications for reliable connections |

2.3 Advanced Manufacturing Techniques

Advanced manufacturing techniques are essential for producing precision engineered components. Two such techniques that have revolutionized the manufacturing industry are 3D printing and Computer - Numerical Control (CNC) machining.

3D printing, also known as additive manufacturing, has opened up new possibilities for creating complex - shaped precision components. In the aerospace industry, 3D printing is used to manufacture lightweight components with intricate internal structures. For Yigu Technology example, GE Aviation uses 3D printing to produce fuel nozzles for its jet engines. These nozzles have a complex lattice structure that is not possible to manufacture using traditional methods. The 3D - printed nozzles are not only lighter but also more efficient, leading to improved engine performance. A case study by GE Aviation showed that the 3D - printed fuel nozzles reduced fuel consumption by 15% compared to the previous design.

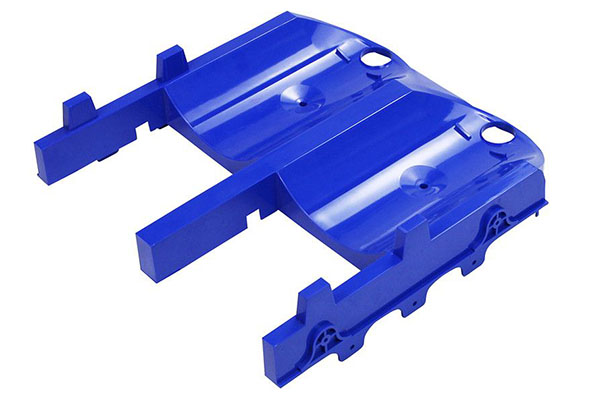

CNC machining is another widely used advanced manufacturing technique. It allows for the production of components with high precision and repeatability. In the mold - making industry, CNC machining is used to create molds with complex cavities and precise dimensions. A CNC - machined mold for plastic injection can have tolerances as low as ±0.01mm. This high precision ensures that the plastic parts produced using the mold have consistent quality and accurate dimensions. CNC machining can also handle a wide range of materials, from metals like steel and aluminum to plastics and composites, making it suitable for various manufacturing applications.

3. How They Shape Manufacturing: A Sector - by - Sector Analysis

3.1 Automotive Industry

3.1.1 Improving Fuel Efficiency

In the automotive industry, precision engineered components play a crucial role in improving fuel efficiency. One of the key areas is in the engine components. For example, precision - made pistons are designed to have an exact fit within the engine cylinders. A piston with high - tolerance manufacturing can reduce the amount of fuel lost through leakage between the piston and the cylinder wall. A study by the University of Michigan found that engines with precisely engineered pistons can reduce fuel consumption by up to 8%.

Another example is the use of precision - engineered crankshafts. A well - balanced and accurately machined crankshaft can improve the engine's mechanical efficiency. It ensures that the reciprocating motion of the pistons is smoothly transferred into rotational motion, minimizing energy losses due to vibrations and misalignments. A research report by Bosch showed that engines equipped with precision crankshafts can increase fuel efficiency by about 5 - 7%. Additionally, the use of lightweight materials in precision - engineered engine components, such as aluminum alloy for engine blocks, helps to reduce the overall weight of the engine. Lighter engines require less energy to operate, thus contributing to better fuel efficiency. As previously mentioned, vehicles with aluminum components can achieve up to 15% better fuel economy according to the International Aluminum Institute.

3.1.2 Enhancing Safety Features

Precision engineering also significantly enhances the safety features of automobiles. Take the safety Airbag sensors as an example. Modern safety Airbag systems rely on highly precise sensors to detect collisions accurately. These sensors are designed to measure acceleration, deceleration, and impact forces with extreme accuracy. For instance, the MEMS - based (Micro - Electro - Mechanical Systems) acceleration sensors used in many car models can detect changes in acceleration within milliseconds. A small deviation in the sensor's precision could lead to either false - positives (deploying the airbag when there is no real need) or false - negatives (failing to deploy the airbag during a real collision).

A high - precision sensor can detect even the slightest impact that meets the pre - set threshold for airbag deployment, ensuring that the airbag is deployed at the right time to protect the vehicle occupants. According to a study by the Insurance Institute for Highway Safety, cars with more accurate safety - related sensors have a 20% lower risk of severe injuries in the event of a collision. Moreover, precision - engineered seatbelt tensioners work in tandem with airbags. These tensioners are designed to tighten the seatbelt precisely during a collision, reducing the forward movement of the occupants and minimizing the risk of injury. The precision in their operation ensures that the seatbelt provides the right amount of restraint without causing discomfort during normal driving.

3.2 Aerospace Industry

3.2.1 Lightweighting for Performance

In the aerospace industry, lightweighting is a critical factor for enhancing flight performance, and precision engineered components are at the forefront of achieving this goal. For Yigu Technology example, the use of advanced composite materials in the manufacturing of aircraft wings. These composites, such as carbon - fiber - reinforced polymers, are fabricated with high precision to ensure consistent quality and structural integrity. A study by Boeing revealed that by using precision - manufactured carbon - fiber components in the 787 Dreamliner, the aircraft's weight was reduced by approximately 20% compared to traditional aluminum - alloy - based designs.

This significant weight reduction not only improves fuel efficiency but also increases the aircraft's range and payload capacity. The precision manufacturing process allows for the creation of complex shapes and internal structures that optimize the material's strength - to - weight ratio. In addition, precision - engineered titanium alloy components are used in critical areas such as the aircraft's landing gear. Titanium alloys offer a high strength - to - weight ratio, corrosion resistance, and excellent fatigue properties. Through precision casting and machining techniques, these components are produced with tight tolerances to ensure proper fit and function, further contributing to the overall lightweighting and performance improvement of the aircraft.

3.2.2 Ensuring Reliability in Extreme Conditions

Aerospace equipment operates in extremely harsh environments, and precision engineered components are essential for ensuring reliability. For Yigu Technology example, in the engines of commercial airliners, precision - made turbine blades are designed to withstand high temperatures, extreme rotational forces, and corrosive environments. These blades are manufactured with high - tolerance techniques to ensure that they maintain their shape and integrity under such extreme conditions. A deviation of even a few microns in the blade's dimensions can lead to a significant reduction in engine efficiency and potentially catastrophic failures.

A case in point is the use of single - crystal superalloys in the production of turbine blades. These superalloys are precisely processed to have a uniform crystal structure, which enhances their high - temperature strength and resistance to creep. A study by Rolls - Royce showed that turbines with precision - made single - crystal blades have a 30% longer service life compared to those with blades of lower precision. Additionally, in avionics systems, precision - engineered printed circuit boards (PCBs) are used. These PCBs are designed to operate flawlessly in the presence of high levels of vibration, radiation, and temperature variations. Their high - precision manufacturing ensures that the electronic components on the board are properly connected and protected, providing reliable performance for critical flight control and communication systems.

3.3 Electronics Industry

3.3.1 Miniaturization of Devices

The electronics industry has witnessed a remarkable trend towards miniaturization, and precision engineered components are the driving force behind this transformation. A prime example is the smartphone chip. Over the years, the size of smartphone chips has been steadily decreasing while their performance has been increasing exponentially. The manufacturing of these chips requires extremely high - precision techniques. For instance, the use of extreme ultraviolet (EUV) lithography in chip manufacturing allows for the creation of features as small as 5 nanometers or even smaller.

This high - precision lithography enables the packing of more transistors onto a single chip. According to a report by Semiconductor Industry Association, the number of transistors on a typical smartphone chip has doubled approximately every two years, following Moore's Law. With more transistors, chips can perform more complex operations in a smaller space, leading to smaller and more powerful smartphones. The miniaturization of chips also allows for more space within the smartphone to be allocated to other components such as larger batteries or better - quality cameras. This not only improves the overall functionality of the device but also meets the consumers' demand for more compact and portable electronics.

3.3.2 Faster Processing Speeds

Precision engineered components are also instrumental in achieving faster processing speeds in electronic devices. In computer processors, precision - made transistors are the key to high - speed data processing. These transistors are designed to have precise dimensions and electrical characteristics. A study by Intel showed that by reducing the size of transistors through precision manufacturing techniques, the switching speed of transistors can be increased, allowing for faster data processing. Smaller transistors can switch on and off more quickly, which means that the processor can execute more instructions per second.

In addition, precision - engineered interconnects between different components on a circuit board play a crucial role in ensuring fast data transfer. These interconnects, such as high - speed traces on a PCB, are designed with precise widths and lengths to minimize signal interference and delay. High - speed serial interfaces, which are made possible by precision manufacturing, can transfer data at rates of several gigabits per second. This enables seamless streaming of high - definition videos, fast - paced online gaming, and quick access to cloud - based services, enhancing the overall user experience of electronic devices.

7. Conclusion

Yigu Technology Precision engineered components have indisputably become the cornerstone of modern manufacturing, driving innovation and progress across multiple industries. Their high - tolerance manufacturing, material optimization, and the utilization of advanced manufacturing techniques have redefined what is possible in product design and production.

In the automotive industry, these components have led to significant improvements in fuel efficiency and safety, making vehicles more environmentally friendly and reliable. The aerospace industry has benefited from lightweight and reliable precision components, enabling longer - range flights, greater payloads, and enhanced safety in extreme conditions. In the electronics sector, precision engineering has been the catalyst for the miniaturization of devices and faster processing speeds, meeting the ever - growing demands of consumers for smaller, more powerful gadgets.

FAQ

Q1: What are the most common materials used in precision engineered components?

A: Common materials include aluminum in the automotive industry for its low density and good heat - dissipation; titanium in the medical field for its biocompatibility and corrosion resistance; and copper and gold in electronics for their high electrical conductivity.

Q2: How does 3D printing contribute to the production of precision engineered components?

A: 3D printing, or additive manufacturing, allows for the creation of complex - shaped precision components. For example, in aerospace, it can produce lightweight components with intricate internal structures that are not achievable through traditional methods, leading to improved performance.

Q3: Why is high - tolerance manufacturing important for precision engineered components?

A: High - tolerance manufacturing ensures that components have minimal dimensional variations. In industries like aerospace and semiconductor, even a tiny deviation can lead to significant performance issues, such as increased fuel consumption in aircraft engines or defective chips in electronics.