High-Tech Injection Molding: How It Works and Why You Need It

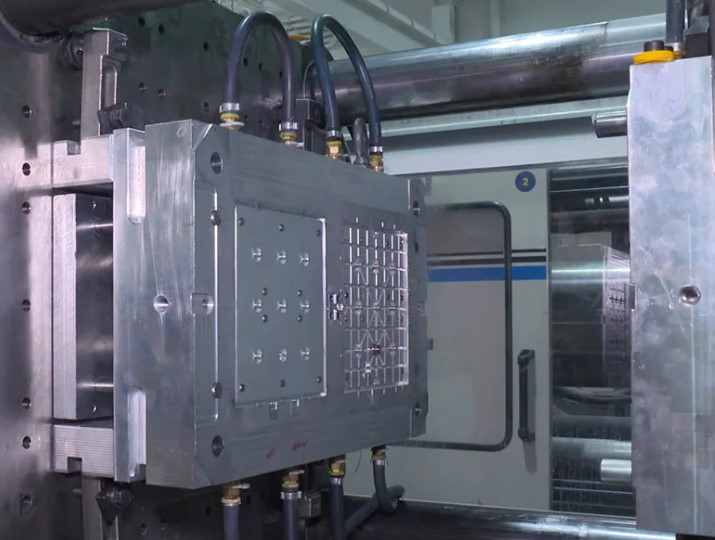

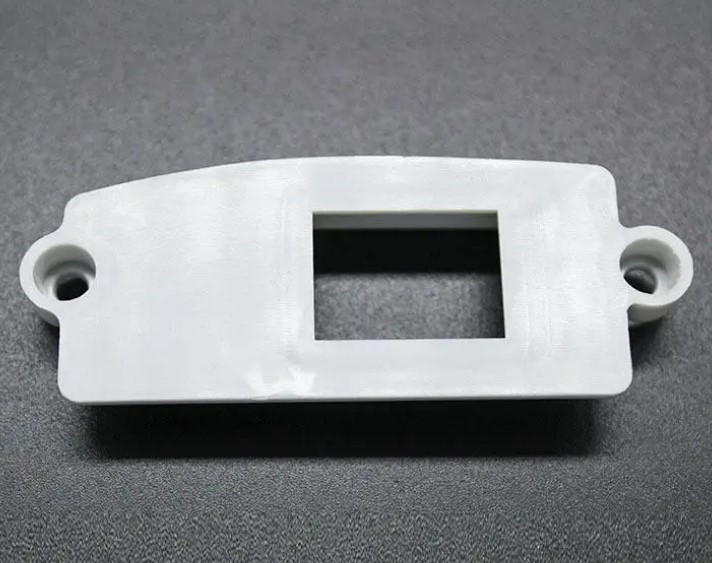

High-tech injection molding is a super cool way to make complex plastic parts with the help of cutting-edge tech. It mixes old school molding tricks with fancy new machines and digital smarts. Here's why it's so important for many industries: First off, the machines used are top of the line. They have things like servo […]

High-Tech Injection Molding: How It Works and Why You Need It Read More »