What is Precision CNC Turning?

Precision CNC turning is a highly advanced manufacturing process that combines the precision of computer numerical control (CNC) technology with the traditional lathe - based turning operation. At its core, it involves the rotation of a workpiece on a lathe while a cutting tool, which remains stationary or moves in a controlled manner, removes material to create the desired shape.

The Basics of CNC Technology

CNC technology revolutionized the manufacturing industry by replacing manual controls with computer - controlled systems. In a precision CNC turning setup, a pre - programmed computer software dictates the movement of the lathe's axes (usually X, Y, and Z axes, and sometimes additional rotational axes like A and B). This software is incredibly detailed, specifying every minute movement of the cutting tool, including feed rates, spindle speeds, and depth of cuts. For Yigu Technology example, a typical precision CNC turning job might require the spindle to rotate at speeds ranging from a few hundred to tens of thousands of revolutions per minute (RPM), depending on the material being processed and the complexity of the part.

The Turning Process

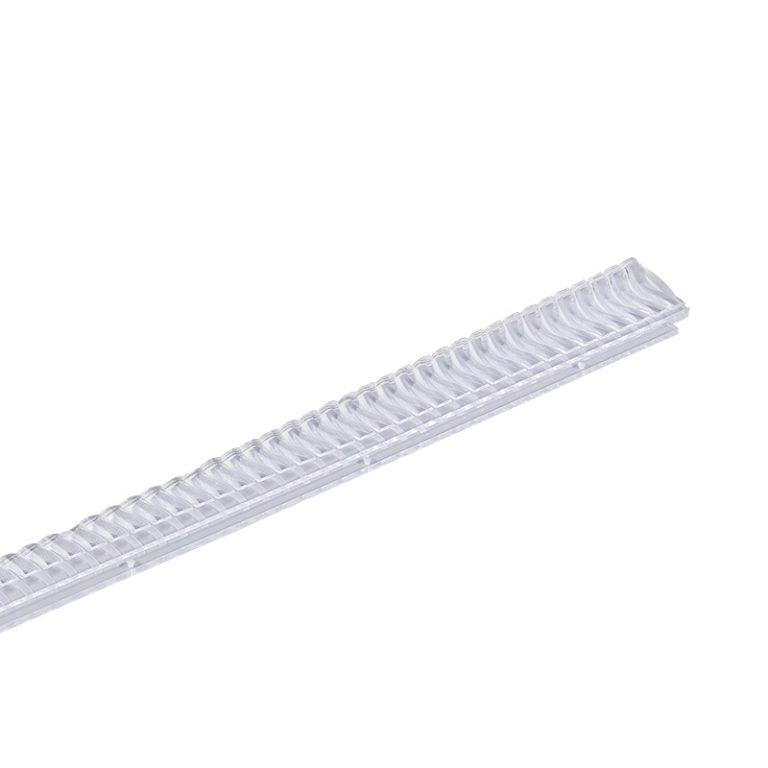

The turning process in precision CNC turning is all about material removal. As the workpiece rotates, the cutting tool, which can be a single - point or multi - point tool, comes into contact with the workpiece. The tool's edge gradually shears away layers of the material, creating a smooth surface finish and the desired shape. This could range from simple cylindrical shapes to highly complex geometries with tight tolerances. For instance, in the production of medical implants, precision CNC turning is used to create components with diameters as small as a few millimeters, where the tolerance requirements can be as tight as ±0.001 mm.

To better understand the key differences between traditional turning and precision CNC turning, let's take a look at the following comparison table:

| Aspect | Traditional Turning | Precision CNC Turning |

| Control Method | Manual operation by a machinist | Computer - programmed control |

| Accuracy | Generally less precise, with tolerances in the range of ±0.1 - 0.5 mm | High precision, with tolerances often as tight as ±0.001 - 0.01 mm |

| Complexity of Shapes | Limited to relatively simple shapes due to manual control | Can create highly complex 3D geometries with ease |

| Production Speed | Slower, especially for complex parts, as it depends on the machinist's skill and speed | Faster for most operations, as the machine can execute commands rapidly without breaks |

| Operator Skill Requirement | High - skilled machinists are needed to ensure accuracy and quality | Operators need to understand CNC programming and machine operation, but the machine does most of the precision work |

This process forms the foundation of precision CNC turning, enabling the creation of high - quality components across various industries. In the next section, we'll explore the industries that benefit most from this remarkable manufacturing technique.

The Intricate Process

The process of precision CNC turning is a multi - step procedure that requires careful planning, high - end equipment, and skilled operators.

Step 1: Material Selection and Preparation

The journey begins with the selection of the right material. Common materials used in precision CNC turning include metals such as aluminum, stainless steel, titanium, and brass, as well as engineering plastics like PEEK (Polyether - ether - ketone) and nylon. Each material has its own unique properties, such as hardness, machinability, and thermal expansion coefficient, which need to be considered based on the requirements of the final product. For Yigu Technology example, aluminum is often chosen for its lightweight and good thermal conductivity, making it suitable for components in the aerospace and automotive industries where heat dissipation is crucial.

Once the material is selected, it needs to be prepared. This usually involves cutting the raw material to the appropriate size and shape to fit into the CNC lathe. The material may also need to be pre - treated, such as annealing (heating and slowly cooling) to reduce internal stresses in metals, which can affect the machining process and the final product's quality.

Step 2: CNC Programming

After material preparation, the next crucial step is CNC programming. A skilled programmer creates a detailed set of instructions for the CNC machine. This program defines the movement of the cutting tool, the spindle speed, the feed rate, and the depth of cuts. The programming can be done using CAM (Computer - Aided Manufacturing) software, which takes a 3D model of the part and generates the necessary G - codes (a standard programming language for CNC machines).

For instance, if we are creating a complex shaft with multiple diameters and threads, the CAM software will calculate the optimal tool paths. It will determine how the cutting tool should move along the X, Y, and Z axes of the lathe to create the desired shape. The spindle speed might be set at 5000 RPM for rough cutting of a soft aluminum alloy to quickly remove large amounts of material, and then reduced to 2000 RPM for fine finishing to achieve a smooth surface finish. The feed rate, which is the speed at which the cutting tool advances along the workpiece, could be set at 0.1 mm/rev for rough cutting and 0.05 mm/rev for finishing.

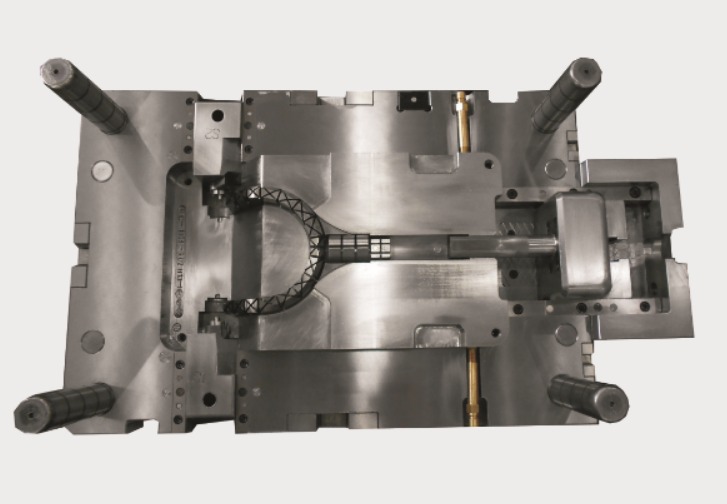

Step 3: Setup of the CNC Lathe

Before the actual machining begins, the CNC lathe needs to be set up. This includes mounting the workpiece onto the chuck or fixture on the lathe's spindle. The chuck holds the workpiece firmly in place during rotation. Special fixtures may be required for complex - shaped workpieces to ensure accurate positioning and stability.

The cutting tools are also installed in the tool holder. CNC lathes often have multiple tool positions, allowing for quick tool changes during the machining process. Each tool is precisely calibrated to ensure its position relative to the workpiece is accurate. This calibration is crucial as even a small deviation can lead to dimensional errors in the final product.

Step 4: Machining Operations

With the setup complete, the machining operations commence. The lathe's spindle starts rotating the workpiece at the programmed speed. The cutting tool, following the instructions from the CNC program, moves towards the workpiece.

The first operation is usually rough turning, where the goal is to quickly remove a large amount of material to get close to the desired shape. This is followed by finish turning, which focuses on achieving the final dimensions and surface finish. For Yigu Technology example, in the production of a high - precision bearing shaft, the rough turning might remove most of the excess material, leaving only a small amount (say, 0.5 - 1 mm) for the finish turning. During finish turning, the cutting tool carefully trims the workpiece to the exact dimensions, with tolerances as tight as ±0.001 mm, and creates a smooth surface finish with a roughness value (Ra) of 0.2 - 0.4 μm.

Other operations that may be performed during precision CNC turning include threading (both internal and external), boring (enlarging an existing hole), and facing (creating a flat surface perpendicular to the axis of rotation).

Step 5: Quality Control and Inspection

Throughout the machining process and after its completion, strict quality control measures are in place. In - process inspection may involve using sensors on the CNC machine to monitor factors such as tool wear, vibration, and temperature. If any of these parameters deviate from the acceptable range, the machine can be programmed to stop automatically to prevent defective parts from being produced.

Once the part is machined, it undergoes a comprehensive inspection. This can include using measuring instruments such as coordinate measuring machines (CMMs), which can accurately measure the dimensions of the part. Optical comparators may also be used to compare the actual shape of the part with the design blueprint. Surface roughness testers are employed to ensure that the surface finish meets the required standards. Only parts that pass these rigorous inspections are considered suitable for use in the final products.

Applications Galore

Precision CNC turning has found its way into a vast number of industries, revolutionizing the manufacturing processes and enabling the production of high - performance components.

Aerospace Industry

In the aerospace sector, precision is non - negotiable. Components such as turbine blades, engine shafts, and landing gear parts are manufactured using precision CNC turning. For Yigu Technology example, turbine blades in jet engines must withstand extreme temperatures and high rotational speeds. Precision CNC turning allows for the creation of blades with complex airfoil shapes and tight tolerances. These tolerances are often in the range of ±0.001 - 0.005 mm. A leading aerospace manufacturer was able to reduce the weight of their engine shafts by 15% through precision CNC turning while maintaining the highest level of strength and durability. This weight reduction directly translated into improved fuel efficiency, with a reported 8% increase in miles per gallon for their commercial aircraft fleet.

Automotive Manufacturing

The automotive industry relies heavily on precision CNC turning for the production of engine components like crankshafts, camshafts, and pistons. Crankshafts, which are crucial for converting the reciprocating motion of pistons into rotational motion, require extremely high precision. Precision CNC turning can achieve roundness tolerances of less than 0.002 mm for crankshaft journals. A major automotive company saw a 20% reduction in engine vibration levels after switching to precision CNC - turned crankshafts. This not only improved the smoothness of the engine operation but also increased the lifespan of the engine by 15% due to reduced wear and tear.

Medical Equipment

Medical implants, such as hip and knee replacements, dental implants, and surgical instruments, are made with precision CNC turning. For hip implants, the femoral stem needs to have a precise fit within the femur bone. Precision CNC turning can create femoral stems with surface roughness values as low as Ra 0.1 - 0.2 μm, which is essential for osseointegration (the process by which the implant fuses with the bone). In a clinical study, patients with hip implants made using precision CNC turning showed a 30% faster recovery time compared to those with implants made using traditional manufacturing methods.

Electronics

In the electronics industry, precision CNC turning is used to create components for devices like smartphones, laptops, and high - end audio equipment. For example, the aluminum housings of smartphones are often precision CNC - turned to achieve a sleek and durable design. These housings can have wall thicknesses as thin as 0.5 - 1 mm, with tight dimensional tolerances to ensure a perfect fit for internal components. A well - known electronics brand was able to increase the structural integrity of their smartphone housings by 25% through precision CNC turning, reducing the number of warranty claims due to damaged housings by 40%.

Quality Control in Precision CNC Turning

Quality control is the cornerstone of precision CNC turning, ensuring that the final products meet the highest standards of accuracy, reliability, and functionality. Given the tight tolerances and complex geometries involved in precision CNC turning, even the slightest deviation can render a part unusable or, in critical applications like aerospace and medical devices, pose serious risks.

In - Process Monitoring

One of the key aspects of quality control is in - process monitoring. Modern CNC machines are equipped with a variety of sensors. For example, tool - wear sensors can detect the gradual wear of the cutting tool during machining. As the tool wears, it can affect the dimensions and surface finish of the workpiece. By continuously monitoring tool wear, the CNC system can automatically adjust the cutting parameters or prompt the operator to change the tool before significant errors occur.

Vibration sensors are another crucial component. Excessive vibration during machining can lead to poor surface finish, dimensional inaccuracies, and even tool breakage. The vibration sensors measure the amplitude and frequency of vibrations in the machine. If the vibration levels exceed the preset limits, the machine can either reduce the cutting speed or adjust the feed rate to minimize the vibration.

Post - Machining Inspection

After the machining process is complete, a comprehensive post - machining inspection takes place. Coordinate measuring machines (CMMs) are widely used for this purpose. A CMM uses a probe to measure the coordinates of points on the workpiece's surface. It can accurately measure linear dimensions, angles, and the position of features on the part. For a precision - turned component with a nominal diameter of 10 mm and a tolerance of ±0.001 mm, a CMM can precisely determine if the actual diameter falls within this tight tolerance range.

Optical comparators are also valuable inspection tools. They project a magnified image of the part onto a screen and compare it with a pre - programmed template of the ideal part. This allows for quick and easy identification of any shape deviations. Surface roughness testers, on the other hand, measure the microscopic irregularities on the surface of the workpiece. In industries like medical equipment manufacturing, where a smooth surface finish is crucial for biocompatibility, surface roughness testers ensure that the surface roughness values meet the required standards, such as Ra 0.1 - 0.2 μm for hip implants.

Quality Management Systems

Implementing a robust quality management system (QMS) is essential for maintaining consistent quality in precision CNC turning. A QMS typically includes documented procedures for every step of the manufacturing process, from material inspection to final product release. It also involves regular calibration of measuring equipment to ensure accurate measurements. For example, CMMs should be calibrated at least once a year using certified calibration standards.

Employee training is another critical element of a QMS. Operators and quality inspectors need to be well - trained in the use of inspection equipment, understanding of quality standards, and the ability to identify and correct potential quality issues. Regular audits are conducted to ensure that the QMS is being followed correctly, and any non - conformities are promptly addressed through corrective and preventive actions.

FAQ

What materials are suitable for precision CNC turning?

Common materials suitable for precision CNC turning include metals such as aluminum, which is lightweight, has good thermal conductivity, and is highly machinable, making it ideal for aerospace and automotive applications. Stainless steel is another popular choice, known for its corrosion - resistance and strength, used in applications where durability and hygiene are crucial, like in the medical and food industries. Titanium offers an excellent strength - to - weight ratio and high heat resistance, making it suitable for aerospace and high - performance automotive components. Brass, with its good machinability and electrical conductivity, is often used in electrical and plumbing components. Engineering plastics such as PEEK (Polyether - ether - ketone) and nylon are also used. PEEK has high - temperature resistance, chemical resistance, and mechanical strength, while nylon is known for its toughness and self - lubricating properties.

How to ensure the accuracy of precision CNC turning?

To ensure the accuracy of precision CNC turning, several key steps should be taken. First, proper CNC programming is essential. The program should be carefully written to precisely define the tool paths, spindle speeds, feed rates, and depths of cuts. Using high - quality CAM (Computer - Aided Manufacturing) software can help generate accurate G - codes. Second, the CNC lathe must be well - maintained and calibrated regularly. This includes checking and adjusting the alignment of the axes, ensuring the spindle runs smoothly with minimal vibration, and calibrating the measuring systems on the machine. Third, the selection of high - quality cutting tools and proper tool installation are crucial. Tools should be sharp and accurately positioned in the tool holder. Fourth, in - process monitoring using sensors to detect tool wear, vibration, and temperature can help in making real - time adjustments to maintain accuracy. Finally, post - machining inspection with precise measuring instruments like coordinate measuring machines (CMMs) and optical comparators can verify the accuracy of the finished part.

What are the common problems in precision CNC turning and how to solve them?

One common problem is surface roughness. This can be caused by factors such as improper tool selection, tool wear, incorrect cutting parameters (such as too high or too low cutting speed, or inappropriate feed rate), and machine vibration. To solve this, select the right tool for the material and application, regularly check and replace worn - out tools, optimize the cutting parameters based on the material and part requirements, and ensure the machine is properly maintained and free from excessive vibration. Another problem is dimensional inaccuracies. These can result from incorrect programming, thermal expansion of the workpiece or machine components, and tool wear. To address this, double - check the CNC program for errors, compensate for thermal expansion by controlling the machining environment temperature, and monitor and manage tool wear effectively. Issues with chip formation, such as long, stringy chips that can interfere with the machining process, can be resolved by adjusting the cutting parameters or using chip - breaking tools.