1. Introduction

In the ever - evolving landscape of modern manufacturing, CNC (Computer Numerical Control) machining has emerged as a cornerstone technology. It serves as the driving force behind the production of countless components across a wide array of industries, from aerospace and automotive to medical devices and electronics. The ability of CNC machining to create complex, high - precision parts with repeatability has revolutionized manufacturing processes.

The demand for precision in manufacturing is insatiable. Whether it's a tiny component in a smartphone that needs to fit perfectly with other parts or a critical aerospace part that must withstand extreme conditions, precision is non - negotiable. This is where CNC machining companies play a crucial role. They are constantly striving to push the edge of precision, and in this article, we will explore the various ways they achieve this remarkable feat.

2. The Basics of CNC Machining Precision

2.1 Definition of Precision in CNC Machining

In CNC machining, precision is a multi - faceted concept. Size accuracy refers to how closely the actual dimensions of a machined part match the designed dimensions. It is typically measured in terms of tolerance. For example, if a part is designed to have a diameter of 10 mm with a tolerance of ±0.01 mm, a high - precision CNC machining process will ensure that the produced part's diameter falls within the range of 9.99 - 10.01 mm.

Shape accuracy pertains to the degree to which the actual shape of the machined part conforms to the intended shape. This includes aspects such as roundness, straightness, and flatness. For a circular component, high shape accuracy means that the machined circle is as close as possible to a perfect geometric circle, with minimal deviations in its circularity.

Position accuracy deals with the relative positions of different features on a part. For instance, in a multi - hole component, position accuracy ensures that the holes are located precisely where they are supposed to be in relation to each other and to other features of the part. If two holes are designed to be 50 mm apart with a position tolerance of ±0.05 mm, a precise CNC machining operation will guarantee that the actual distance between the centers of the two holes is within this tolerance range.

2.2 Why Precision Matters

High precision in CNC machining is of utmost importance for several reasons.

Product Performance: In the aerospace industry, components like turbine blades in jet engines need to be manufactured with extremely high precision. These blades operate in high - temperature, high - pressure, and high - speed environments. A deviation of even a few micrometers in their shape or dimensions can lead to unbalanced rotation, reduced engine efficiency, and potentially catastrophic failures. According to industry studies, a 0.1% increase in the precision of turbine blade manufacturing can lead to a 3 - 5% improvement in engine fuel efficiency.

Product Quality: For medical devices such as surgical instruments, precision is critical for ensuring their functionality and safety. A scalpel blade, for example, needs to have a precise edge geometry and sharpness. If the edge is not accurately machined, it may not cut smoothly, leading to increased trauma during surgical procedures. In the electronics industry, precision - machined components in smartphones, like the connectors and micro - components, ensure reliable electrical connections. A poorly machined connector can cause intermittent signal loss or overheating issues.

Cost - effectiveness: Although achieving high precision may require more advanced equipment and skilled operators, it can ultimately save costs. Precise machining reduces the number of defective parts. In a large - scale production of automotive engine components, if the precision is not maintained, a significant number of parts may need to be reworked or scrapped. A study by a leading automotive manufacturer found that by improving the precision of CNC machining for engine blocks from ±0.1 mm to ±0.05 mm, the rework rate decreased by 40%, resulting in substantial cost savings in terms of both materials and labor.

3. Technological Advancements Driving Precision

3.1 High - Precision CNC Machines

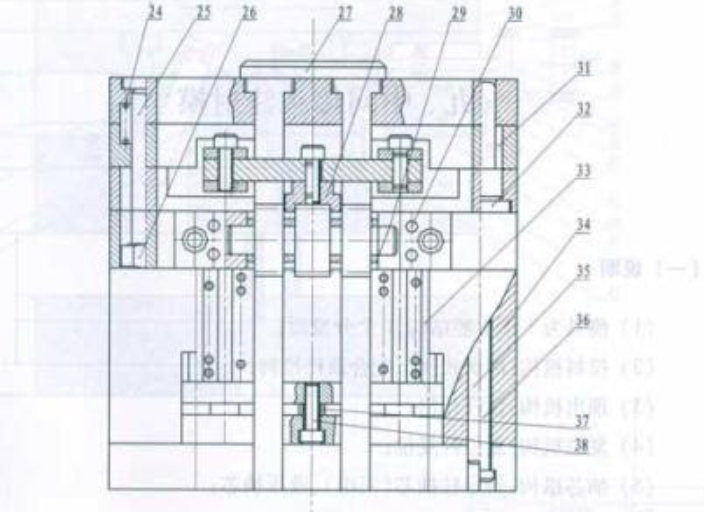

One of the primary drivers of precision in CNC machining is the continuous evolution of high - precision CNC machines. Take, for example, five - axis 联动加工中心. These advanced machines are far more sophisticated than traditional three - axis CNC machines.

Traditional three - axis machines are limited to linear movements along the X, Y, and Z axes. This restricts their ability to machine complex geometries in a single setup. In contrast, five - axis machines add two additional rotational axes, typically denoted as A and C axes. This allows the workpiece or the tool to be rotated and tilted, enabling the machining of complex curved surfaces and parts with multiple features from various angles without the need for re - clamping the workpiece.

The precision advantages of five - axis machines are significant. They can achieve a positioning accuracy of up to ±0.001 mm, while traditional three - axis machines usually have a positioning accuracy in the range of ±0.01 - 0.05 mm. In the aerospace industry, when manufacturing turbine blades, five - axis CNC machines can produce blades with a surface finish roughness of less than 0.8 μm, compared to 1.6 - 3.2 μm achievable by some traditional machines. This higher precision and better surface finish are crucial for the performance and efficiency of the turbine blades.

3.2 Advanced Tooling Systems

The development of advanced tooling systems also plays a pivotal role in enhancing CNC machining precision. Newer Tool material and innovative Tool design are constantly emerging.

For instance, the use of Coated cutting tools has become widespread. These tools have a thin layer of coating, such as titanium nitride (TiN), titanium carbonitride (TiCN), or diamond - like carbon (DLC), applied to their surface. This coating serves multiple purposes. It significantly reduces friction between the tool and the workpiece during machining, which in turn minimizes heat generation. Less heat means less thermal expansion of the tool and the workpiece, leading to more consistent machining accuracy. The coating also improves the tool's wear resistance. A study showed that a TiN - coated carbide end - mill had its tool life extended by 2 - 3 times compared to an uncoated one when machining stainless steel. This longer tool life ensures that the tool maintains its cutting edge geometry for a more extended period, contributing to consistent precision over multiple machining operations.

In terms of Tool design,modern tools are often engineered with complex geometries to optimize cutting performance. For example, some end - mills are designed with variable helix angles. This design reduces the likelihood of chatter during machining, which can cause dimensional inaccuracies. By minimizing chatter, these end - mills can achieve a more accurate surface finish and dimensional control, especially when machining materials that are prone to vibration - induced errors, such as aluminum alloys.

3.3 Precision Measuring and Inspection Equipment

Precision measuring and inspection equipment is essential for maintaining and validating the precision of CNC - machined parts. Coordinate Measuring Machines (CMMs) are widely used in the industry for this purpose.

CMMs use a probe to measure the coordinates of points on a workpiece's surface. They can accurately measure linear dimensions, angles, and geometric features such as flatness, roundness, and straightness. In a high - precision CNC machining process, CMMs are used at various stages. Before machining, they can be used to measure the raw material to ensure its dimensions are within the required tolerances. During machining, in - process inspection using CMMs can provide real - time feedback. For example, if a deviation is detected in the dimensions of a part being machined, the CNC machine's parameters can be adjusted immediately to correct the error.

After machining, CMMs conduct final inspections to verify that the part meets all the design specifications. High - end CMMs can achieve measurement accuracies of up to ±0.0005 mm. In the medical device manufacturing industry, when producing orthopedic implants, CMMs are used to ensure that the implant's dimensions are precise to within a few micrometers. This is crucial as an ill - fitting implant can lead to complications during implantation and poor patient outcomes. Other inspection tools, such as optical comparators and laser scanning devices, also contribute to the overall precision control in CNC machining, each with its own advantages in different measurement scenarios.

6. Case Studies of Precision - Pushing CNC Machining Companies

6.1 Company A: Aerospace Component Manufacturing

Company A is a leading CNC machining company specializing in aerospace component production. One of their notable achievements is the manufacturing of turbine engine compressor blades.

The design specifications for these blades are extremely stringent. The length of the blades is designed to be 200 mm with a tolerance of ±0.005 mm. Company A's advanced five - axis CNC machines, equipped with high - precision feedback systems, are able to consistently produce blades within this tight tolerance range. The surface finish of the blades, which is crucial for reducing aerodynamic drag and improving engine efficiency, has a roughness value of less than 0.4 μm.

To achieve this level of precision, Company A also uses state - of - the - art tooling. They employ diamond - coated end - mills for the final machining operations. These tools, combined with their in - house developed machining strategies, ensure that the complex airfoil shapes of the blades are machined with high accuracy. In addition, their inspection process involves the use of high - resolution CMMs and optical scanners. Each blade is inspected at multiple points, and any deviation from the design specifications is immediately detected and corrected. As a result, the reject rate for these compressor blades has been reduced to less than 1%, which is far lower than the industry average of 3 - 5%.

6.2 Company B: Medical Device Component Production

Company B focuses on manufacturing components for medical devices. A recent project involved the production of miniature components for insulin pumps.

These components are extremely small, with some parts having a diameter of only 2 mm. The tolerance requirement for the diameter is ±0.002 mm. Company B utilized micro - machining techniques and high - precision Swiss - type CNC lathes. These lathes are capable of high - speed, high - precision machining, with the ability to achieve a spindle speed of up to 50,000 RPM and a positioning accuracy of ±0.001 mm.

The tooling for this project was also highly specialized. Company B developed custom - designed micro - drills and end - mills with diameters as small as 0.1 mm. These tools were made from ultra - hard materials to ensure long - lasting cutting performance and precision. During the machining process, real - time monitoring of the cutting forces and temperatures was carried out. This data was used to adjust the machining parameters automatically to maintain the required precision.

The final inspection of the components was done using electron microscopes and high - magnification optical inspection systems. This allowed for the detection of even the slightest surface defects or dimensional deviations. The success of this project led to a significant increase in the reliability of the insulin pumps, as the precise components ensured accurate insulin delivery. The company's precision - focused approach has also attracted other major medical device manufacturers, leading to a substantial growth in their business.

7. Yigu Technology's Perspective

Yigu Technology, as a non - standard plastic metal custom products Supplier, has its own unique insights and advantages in the pursuit of high - precision CNC machining.

Yigu Technology is equipped with a diverse range of state - of - the - art CNC machining equipment. Their five - axis 联动加工中心 are sourced from leading manufacturers, ensuring high - speed and high - precision operations. These machines can achieve a positioning accuracy of up to ±0.001 mm, which is crucial for producing complex non - standard parts. For plastic components, they use specialized injection molding machines with advanced temperature and pressure control systems. This allows for precise control over the forming process, resulting in plastic parts with tight tolerances. In the case of metal machining, high - speed milling machines and turning centers are employed. These machines are capable of rapid material removal while maintaining the required precision, making them suitable for producing custom metal parts with complex geometries.

8. FAQ

8.1 What is the typical precision range that a high - end CNC machining company can achieve?

A high - end CNC machining company can typically achieve a precision range of ±0.001 - 0.01 mm. For example, in the aerospace industry, where components need to be extremely precise, parts like turbine engine blades are often manufactured with a tolerance of ±0.005 mm. In the medical device industry, for components such as those in implantable devices, a precision of around ±0.01 mm is common to ensure proper fit and function within the human body.

8.2 How does a CNC machining company ensure precision in long - term production runs?

CNC machining companies ensure precision in long - term production runs through several methods. Regular equipment maintenance is crucial. Machines are serviced and calibrated at regular intervals to ensure that their mechanical components are in optimal condition. For instance, the linear guides and ball screws of a CNC machine, which are responsible for the movement of the axes, are inspected and replaced if necessary to maintain positioning accuracy. Process monitoring is also key. Sensors are installed on the machines to monitor factors such as cutting forces, spindle speeds, and temperatures. If any of these parameters deviate from the optimal range, it can affect precision, and the system can be adjusted accordingly. Additionally, high - quality tooling is used, and tools are replaced at appropriate intervals to prevent errors caused by tool wear.

8.3 Can a CNC machining company improve the precision of an existing product design?

Yes, a CNC machining company can improve the precision of an existing product design. They can do this by optimizing the machining process. For example, if the original design was machined using a three - axis CNC machine, switching to a five - axis machine might improve precision as it allows for more complex machining operations in a single setup. Adjusting the machining parameters such as cutting speed, feed rate, and depth of cut can also enhance precision. In the case of a part with a surface roughness issue, changing the cutting parameters can lead to a smoother finish. Another way is to use advanced tooling. Upgrading to a more precise or specialized tool can reduce machining errors. For instance, using a coated end - mill with a more wear - resistant coating can maintain the cutting edge geometry for longer, resulting in more accurate machining over multiple parts.