Aerospace CNC machining plays a pivotal role in the manufacturing of high-precision components used in the aerospace industry. Mold7 explores the key trends driving innovation in aerospace CNC machining and highlights its diverse applications, ranging from structural components to complex engine parts. As the industry demands ever-greater precision, efficiency, and sustainability, CNC machining continues to evolve to meet these challenges.

Introduction to Aerospace CNC Machining

What is Aerospace CNC Machining?

Aerospace CNC machining involves using computer-controlled machinery to create parts from various materials such as metals (aluminum, titanium), composites, and superalloys. The CNC (Computer Numerical Control) machines are programmed to follow precise instructions from CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, enabling the production of highly accurate and intricate parts. Aerospace components must meet strict tolerances and performance requirements, making CNC machining an essential technology in the industry.

Importance in Aerospace Industry

CNC machining is vital to the aerospace industry due to its ability to produce parts that meet exacting standards of precision, reliability, and safety. These parts often function in extreme environments, such as high altitudes, high temperatures, and high pressures, making the integrity of each component crucial to the overall safety and efficiency of aircraft and spacecraft. Furthermore, the use of advanced materials like titanium and carbon fiber composites, which are known for their high strength-to-weight ratios, requires specialized machining techniques to avoid material defects and ensure high performance.

Key Trends in Aerospace CNC Machining

1. Integration of AI and Machine Learning

The use of artificial intelligence (AI) and machine learning (ML) is rapidly increasing in aerospace CNC machining. AI-powered systems can analyze data from sensors embedded in CNC machines to predict maintenance needs, optimize cutting parameters, and detect anomalies. This leads to more efficient production processes, reduced downtime, and higher overall productivity. Machine learning algorithms can also optimize tool paths, minimizing material waste and improving cutting speeds without compromising part quality.

2. Growth of IoT-Connected Machines

The Internet of Things (IoT) has revolutionized the way CNC machines operate. IoT-enabled CNC machines are now capable of communicating with each other and with central systems in real-time. This connectivity allows manufacturers to track machine performance, monitor tool wear, and make adjustments remotely. IoT also enables the collection of vast amounts of data, which can be analyzed to improve machining processes, predict failures, and ensure better quality control across production lines. This shift toward smart, connected machines contributes to greater operational efficiency and reduced costs.

3. Advanced Materials and Machining Techniques

Aerospace manufacturers are increasingly turning to advanced materials such as superalloys, composites (carbon fiber, fiberglass), and high-performance ceramics. These materials offer superior strength-to-weight ratios, corrosion resistance, and thermal stability, which are critical for aerospace applications. However, they are often harder to machine than traditional metals, requiring specialized tooling, advanced cutting techniques, and more precise machine control. As these materials become more widely used, the demand for CNC machining solutions capable of handling them continues to grow.

4. Sustainability in Machining

Sustainability has become a key consideration in aerospace manufacturing, and CNC machining is no exception. Efforts are being made to reduce the environmental impact of machining processes by focusing on energy efficiency, material recycling, and waste reduction. Companies are implementing technologies that optimize cutting strategies to reduce material scrap, improving overall yield. Furthermore, more efficient CNC machines are being developed to reduce energy consumption, and many manufacturers are exploring ways to recycle metal shavings, reducing material waste.

5. Customization and Low-Volume Production

Traditionally, aerospace manufacturing focused on high-volume, standardized production. However, the industry is increasingly embracing customization and low-volume production. With the flexibility of CNC machining and advancements in digital manufacturing, it is now possible to produce low-volume, high-precision parts tailored to specific needs. This trend is especially important as the industry moves toward more specialized, short-run components, such as custom engine parts or unique aircraft configurations. CNC machining enables fast prototyping and the ability to quickly adapt designs for new aircraft models.

Applications of Aerospace CNC Machining

1. Structural Components

The structural components of an aircraft or spacecraft are fundamental to its integrity and performance. CNC machining is widely used to manufacture critical parts like wings, fuselage sections, landing gear, and empennage components. These parts must be both lightweight and strong to ensure efficiency and safety, and CNC machining allows for precise control of material distribution, reducing weight without sacrificing strength.

2. Engine Parts

Engine components, such as turbine blades, compressor disks, and casings, are some of the most complex parts to manufacture in the aerospace industry. These components are exposed to extreme stresses, high temperatures, and corrosive conditions. CNC machining is essential for producing these parts with the high precision required to ensure reliability and performance. The ability of CNC machines to create fine details and achieve tight tolerances is critical for the intricate geometries of engine parts.

3. Landing Gear

Landing gear is a critical component of any aircraft, as it must withstand the immense forces generated during takeoff, landing, and taxiing. CNC machining plays a significant role in producing landing gear components, which require not only strength but also precise weight distribution. CNC machines ensure that landing gear parts meet rigorous safety standards and are manufactured with the necessary strength-to-weight ratio.

4. Interior Components

While aerospace interior components like seats, tray tables, overhead bins, and emergency exit mechanisms are not as visible as structural or engine components, they are equally important for safety and comfort. CNC machining ensures that these components are precisely manufactured to fit within the limited space available and comply with stringent regulations. These parts must also be lightweight to optimize fuel efficiency without compromising durability.

5. Repair and Maintenance

Even after an aircraft is in operation, CNC machining continues to play a crucial role in maintenance and repairs. Parts can wear out or become damaged, necessitating replacement or modification. CNC machining allows for the rapid production of replacement parts, ensuring that aircraft can be serviced with minimal downtime. This capability is especially important for maintaining older aircraft fleets or when producing spare parts for unique or custom designs.

Technologies Used in Aerospace CNC Machining

1. CNC Turning Machines

CNC turning machines are used to create rotationally symmetric parts, such as shafts, gears, and sleeves. These machines rotate the workpiece while a fixed cutting tool removes material. Modern CNC lathes often have multi-axis capabilities, which allow for more intricate and complex shapes to be machined.

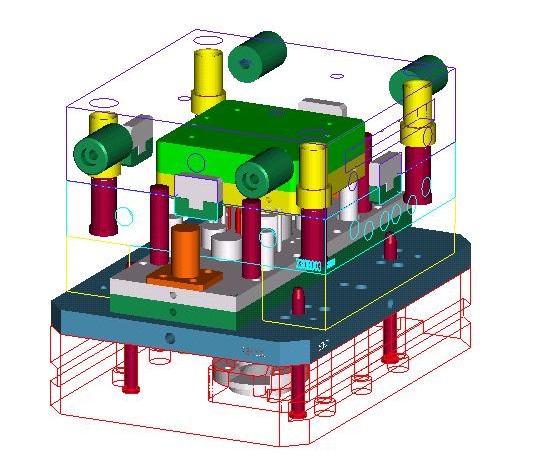

2. CNC Milling Machines

CNC milling machines hold the material stationary while rotating cutting tools remove material. These machines are essential for creating flat surfaces, slots, pockets, and contours. Aerospace manufacturers frequently use 5-axis CNC milling machines, which provide greater flexibility in machining complex geometries, particularly for engine components and aerospace structures.

3. CNC Turnmill Machines

Turnmill machines combine the functionality of both CNC lathes and mills, allowing for both rotational and stationary machining in a single setup. This versatility makes turnmill machines ideal for aerospace components that require both turning and milling operations, saving time and improving efficiency.

4. Grinding Machines

Grinding machines are used to achieve fine surface finishes and remove small amounts of material from a workpiece. In aerospace machining, grinding is essential for finishing hardened steel parts, smoothing edges, and refining intricate features. The high precision offered by grinding ensures that parts meet stringent quality standards.

5. Laser Cutters

Laser cutting uses focused beams of light to cut through materials with high precision. It is ideal for fabricating thin sheets, panels, and brackets with clean, accurate cuts. Laser cutting is particularly useful in aerospace manufacturing, where the demand for precision and minimal heat-affected zones is high.

6. Waterjets

Waterjet cutting uses high-pressure water mixed with abrasive particles to cut through materials. Unlike laser cutting, waterjet cutting does not generate heat, making it ideal for cutting temperature-sensitive materials like composites or alloys that could be damaged by heat. Waterjets are also effective for cutting thick sections without causing cracking or delamination.

Benefits of Aerospace CNC Machining

1. High Precision and Tolerances

Aerospace CNC machining offers unparalleled levels of precision, allowing manufacturers to produce parts with micron-level tolerances. This ensures that all components fit together seamlessly during assembly, which is crucial for ensuring performance, safety, and reliability.

2. Versatility in Material Handling

CNC machining is versatile enough to handle a wide range of materials commonly used in aerospace, from lightweight aluminum to high-strength titanium and composites. This versatility enables manufacturers to select the best material for each application while maintaining consistent quality and performance.

3. Enhanced Safety and Reliability

CNC machines eliminate the human error associated with manual machining processes, improving the safety and reliability of aerospace components. By automating machining tasks, CNC technology reduces the risk of accidents and ensures that parts are produced consistently to high standards, which is critical for the aerospace industry's rigorous safety requirements.

Real-World Case Studies and Success Stories

Efficiency and Quality Improvements at Boeing

Boeing has been using advanced CNC technology extensively in its manufacturing operations. By integrating robotic arms, automated guided vehicles (AGVs), and sophisticated software platforms, Boeing has streamlined its operations, reducing cycle times by up to 40%. This has led to

improvements in both productivity and product consistency.

Airbus A350 XWB Wing Assembly

Airbus leveraged CNC machining technology in the assembly of its A350 XWB wings. The wings are composed of thousands of parts that must be precisely aligned to ensure the correct aerodynamic properties. CNC machinery played a crucial role in achieving this precision, resulting in a highly efficient, fuel-saving design.

The Future of Aerospace CNC Machining

As technology continues to evolve, aerospace CNC machining is poised to play an even more critical role in the development of the next generation of aircraft and spacecraft. From autonomous systems and 3D printing to sustainable practices, CNC machining will continue to drive innovation in aerospace manufacturing, helping to meet the increasing demand for high-performance, lightweight, and cost-effective aerospace solutions.

In conclusion, aerospace CNC machining is a key enabler of innovation in the aerospace industry. As the demand for more complex, efficient, and sustainable designs grows, CNC machining technologies will evolve, ensuring that manufacturers can meet these challenges and continue to push the boundaries of what is possible in aerospace engineering.