Introduction

In the dynamic and highly competitive landscape of engineering manufacturing, Precision Components Ltd has emerged as a trailblazer, revolutionizing the industry with its innovative approaches, cutting - edge technologies, and unwavering commitment to quality. This company has not only managed to keep pace with the ever - evolving demands of the market but has also set new standards, redefining what is possible in the realm of precision engineering.

Precision Components Ltd has been at the forefront of the engineering manufacturing industry for several decades. With a global presence, it serves a diverse range of sectors, from aerospace and automotive to medical and electronics. Its reputation is built on the consistent delivery of high - precision components that meet and often exceed the strictest industry standards. As the engineering manufacturing field continues to face challenges such as the need for miniaturization, increased functionality, and enhanced performance, Precision Components Ltd has been a beacon of innovation, offering solutions that drive progress in these areas. This article delves deep into how Precision Components Ltd is redefining engineering manufacturing, exploring its technological advancements, quality control measures, and customer - centric approach.

Precision - Oriented Quality Control

In precision engineering manufacturing, quality is not just a goal; it is the cornerstone of success. Precision Components Ltd has established a reputation for delivering products of the highest quality, thanks to its stringent quality control measures.

Stringent Quality Standards

Precision Components Ltd adheres to international quality standards, with a particular focus on ISO 9001:2015. This standard is recognized globally for its comprehensive approach to quality management, covering aspects such as customer focus, leadership, engagement of people, process approach, improvement, evidence - based decision making, and relationship management. By following ISO 9001:2015, the company ensures that every aspect of its operations, from design to production and delivery, is optimized for quality.

For example, in the design phase, the company uses the principles of the ISO standard to conduct thorough risk assessments. This involves identifying potential design flaws that could affect the functionality, durability, or safety of the components. By addressing these risks early on, Precision Components Ltd can prevent costly rework and ensure that the final product meets or exceeds customer expectations. In the production process, the ISO - compliant quality management system helps in streamlining operations, reducing waste, and improving overall efficiency. It also ensures that all production processes are well - documented, making it easier to monitor and control quality.

Multi - stage Quality Inspection Process

The company has implemented a multi - stage quality inspection process that begins with the sourcing of raw materials and continues until the final product is shipped to the customer.

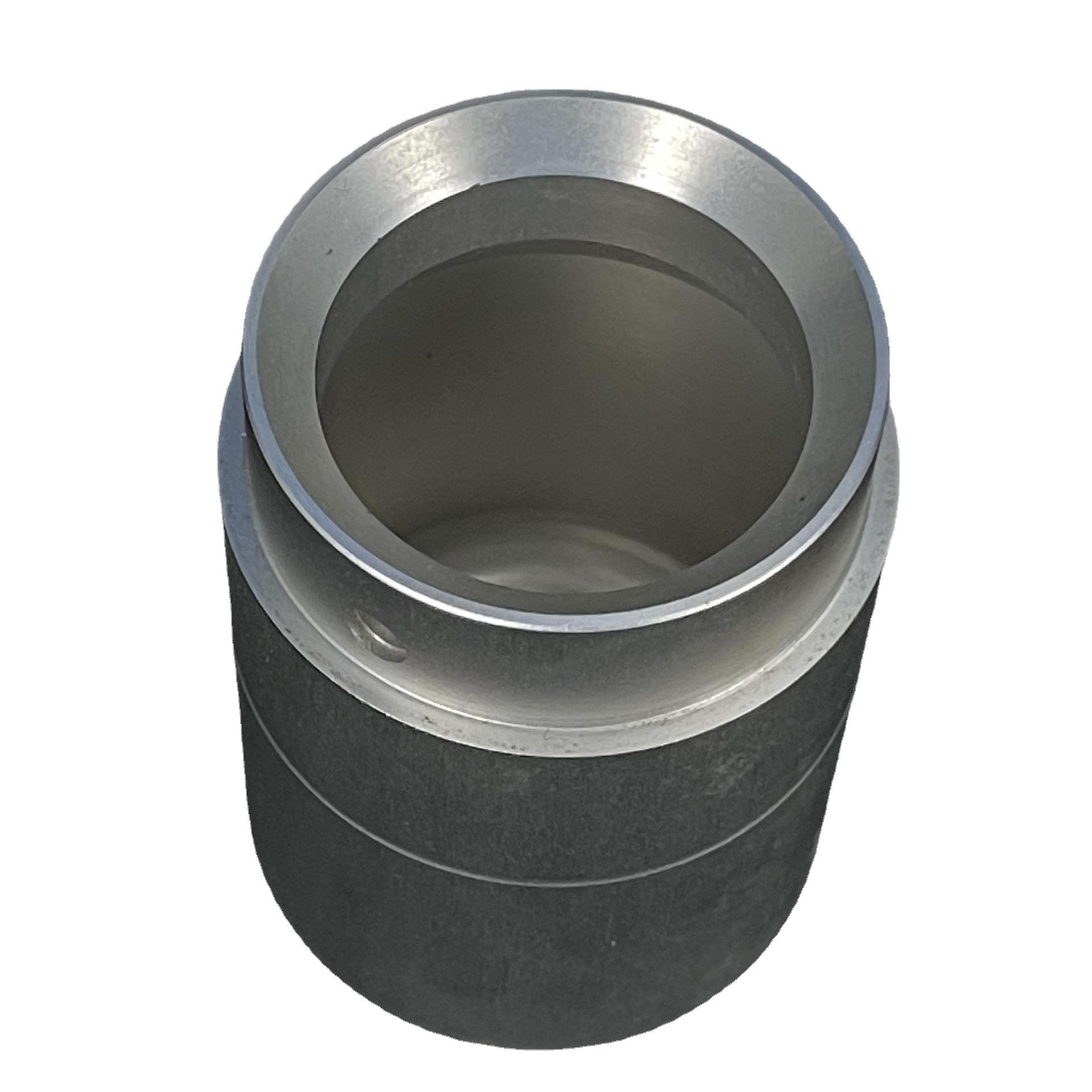

- Raw Material Inspection: When raw materials are received, they undergo a rigorous inspection. For metal components, this includes checks on the chemical composition and mechanical properties. For example, if the company is using aluminum alloy for a particular component, the raw material will be tested to ensure that the alloy contains the correct percentages of elements such as silicon, copper, and magnesium. This is done using advanced spectroscopic analysis equipment. The physical properties, such as hardness and tensile strength, are also tested using specialized testing machines. Only raw materials that meet the strict specifications are approved for use in production.

- In - Process Inspection: During the manufacturing process, components are inspected at various key stages. For instance, in CNC machining, after each major machining operation, the dimensions of the part are checked using high - precision coordinate measuring machines (CMMs). These machines can measure the part's dimensions with an accuracy of up to a few micrometers. Surface finish is also inspected regularly, as a smooth surface is crucial for the proper functioning of many components, especially those in applications like aerospace and medical devices. Any deviations from the set tolerances are immediately identified, and corrective actions are taken. This could involve adjusting the machining parameters or re - machining the part.

- Final Product Inspection: Once the component is fully assembled, it undergoes a comprehensive final inspection. This includes a functional test, where the component is tested under simulated real - world conditions. For example, a component designed for use in an automotive engine will be tested for its performance at different temperatures, pressures, and rotational speeds. Visual inspections are also carried out to check for any cosmetic defects that could affect the product's appearance or marketability. Only components that pass all these tests are considered fit for shipment.

Yigu Technology's Perspective

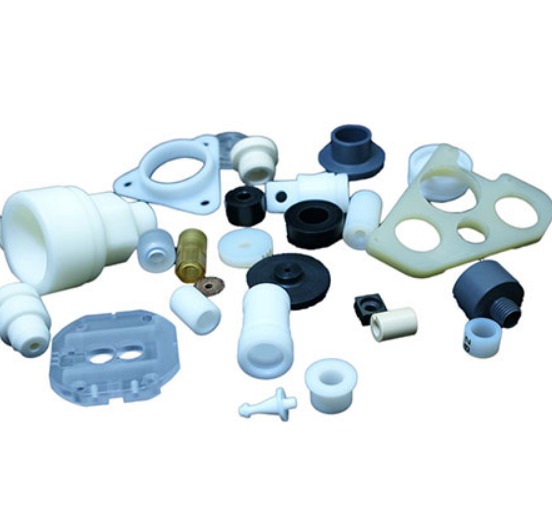

As a non - standard plastic metal products custom Supplier, Yigu Technology highly acknowledges the remarkable achievements of Precision Components Ltd. In the realm of technological innovation, Precision Components Ltd's adoption of advanced manufacturing technologies has set a great example. Yigu Technology believes that such innovation is crucial for the entire industry to keep up with the ever - changing market demands.

In terms of quality control, the multi - stage inspection process implemented by Precision Components Ltd is worthy of learning. Yigu Technology emphasizes that strict quality control is the key to winning the trust of customers. Moreover, the customer - centric approach of Precision Components Ltd also aligns with Yigu Technology's business philosophy. Yigu Technology looks forward to more exchanges and cooperation with Precision Components Ltd and other industry players. It believes that through cooperation, the non - standard plastic metal products industry can achieve greater development, bringing more high - quality products and services to customers.

FAQs

What types of precision components does Precision Components Ltd mainly produce?

Precision Components Ltd mainly produces a wide variety of precision components. These include precision mold components, which are crucial for industries such as plastic injection molding. High - precision mold cores and cavities produced by the company can ensure the accurate replication of complex shapes in plastic products, with dimensional accuracies often reaching within ±0.001mm.

Automation equipment components are another major product line. Components like precision linear guides and high - torque servo motor shafts are manufactured to tight tolerances. For linear guides, the straightness tolerance can be as low as 0.002mm per 1000mm length, enabling smooth and precise linear motion in automation machinery. In the aerospace sector, the company produces critical components such as turbine engine blades. These blades are made from advanced alloy materials and are precision - machined to meet the strict aerodynamic and mechanical requirements of aircraft engines.

How does Precision Components Ltd ensure the precision of its products?

Precision Components Ltd ensures product precision through multiple means. Firstly, it is equipped with state - of - the - art manufacturing equipment. High - precision CNC (Computer Numerical Control) machines are used, which can achieve positioning accuracies of up to ±0.0001mm. These machines are constantly calibrated and maintained to ensure consistent performance.

Secondly, the company has a strict quality control system. As mentioned before, the multi - stage quality inspection process plays a vital role. From raw material inspection to in - process and final product inspections, every step is designed to catch any potential deviations from the required precision. For example, in - process inspections using CMMs can detect dimensional errors early, allowing for immediate corrective actions.

Moreover, the company's professional technical team also contributes to precision. Composed of experienced engineers and technicians, they are proficient in advanced manufacturing techniques and are able to optimize manufacturing processes to achieve the highest level of precision. They can also solve complex technical problems that may arise during production to ensure the precision of the final products.

Can Precision Components Ltd provide customized solutions for special projects?

Yes, Precision Components Ltd has the ability to provide customized solutions for special projects. The customization process usually begins with in - depth communication with the customer to fully understand the specific requirements of the project, including functional, dimensional, and material - related needs. Then, the company's engineering team will design a tailored solution, often using advanced CAD/CAM (Computer - Aided Design/Computer - Aided Manufacturing) software to create detailed 3D models and manufacturing plans.

There are numerous successful cases. For a special medical device project, the customer required a custom - designed precision component with unique biocompatible material requirements and extremely tight tolerances. Precision Components Ltd successfully developed and produced the component. Through a combination of innovative design, precise manufacturing, and strict quality control, the final product met all the customer's requirements, enabling the successful launch of the new medical device.