Imagine spending weeks designing a critical aerospace component, only to have it shatter during machining. Or investing in expensive ceramic materials, yet struggling to achieve the tight tolerances your project demands. These are common headaches for engineers and manufacturers working with ceramics—a material celebrated for its durability and heat resistance, yet notoriously challenging to shape with precision. The solution? CNC machining of ceramics has emerged as a game-changer, but mastering it requires understanding the right materials, tools, and techniques. In this guide, we’ll break down everything you need to know to overcome these challenges and leverage CNC ceramics for your most demanding projects.

Understanding CNC Machining of Ceramics: Processes That Deliver Precision

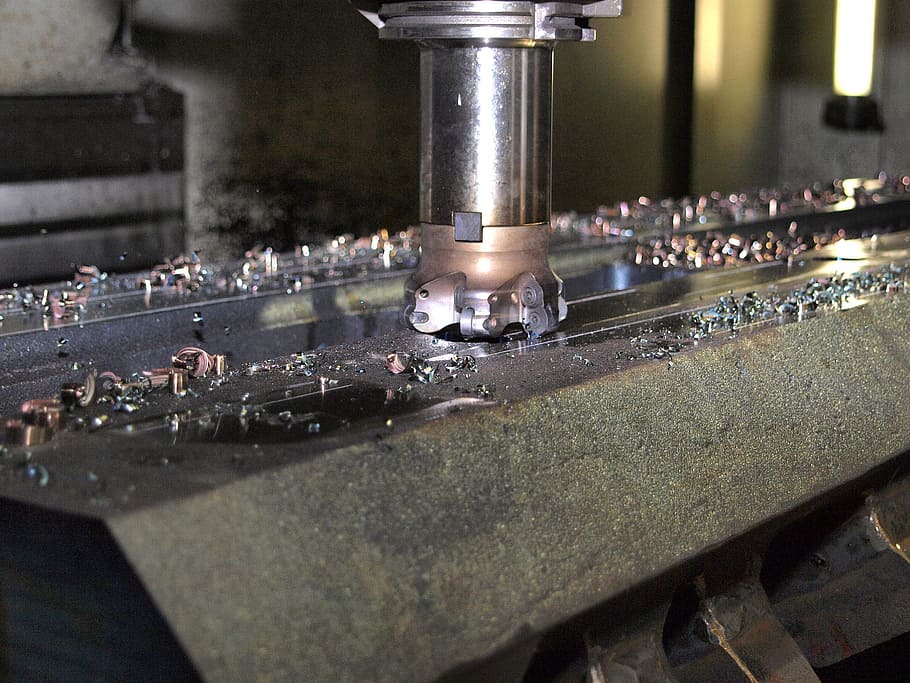

At the core of successful ceramic fabrication lies CNC machining of ceramics—a set of processes that transform hard, brittle ceramic materials into intricate, high-precision parts. Unlike metal machining, where materials yield more easily, ceramics require specialized approaches to avoid cracking or chipping. Let’s explore the key processes:

- CNC milling: Ideal for creating complex 3D shapes, CNC milling uses rotating cutting tools to remove material layer by layer. With ceramics, achieving a smooth surface finish (Ra values as low as 0.02 μm) demands slow feed rates and optimized toolpaths. For example, alumina ceramics often require spindle speeds between 10,000–20,000 RPM to balance precision and material integrity.

- CNC turning: Used for cylindrical parts like shafts or bushings, CNC turning spins the ceramic workpiece against a stationary cutting tool. Here, machining parameters such as depth of cut (typically 0.1–0.5 mm) and feed rate (50–200 mm/min) are critical. A study by the International Journal of Advanced Manufacturing Technology found that reducing feed rates by 30% decreased ceramic chipping by up to 65%.

- Toolpath optimization: Software algorithms that minimize sudden direction changes can reduce stress on the ceramic. Contour-parallel toolpaths, for instance, distribute cutting forces more evenly than zig-zag patterns, lowering the risk of fracture.

Ceramic Materials for CNC: Choosing the Right Foundation

Not all ceramics are created equal. The success of your CNC project hinges on selecting a material that aligns with your application’s needs. Here’s how the most popular options stack up:

| Material | Hardness (HV) | Thermal Conductivity (W/m·K) | Mechanical Strength (MPa) | Best For |

| Alumina ceramics | 1500–2000 | 20–30 | 300–400 | Insulators, wear parts |

| Zirconia ceramics | 1200–1600 | 2–3 | 800–1200 | Medical implants, bearings |

| Silicon carbide | 2200–2800 | 80–200 | 400–600 | High-temperature components |

| Ceramic composites | 1800–2500 | 30–150 | 500–900 | Aerospace parts, armor |

Material properties like hardness and thermal conductivity directly impact machining. For example, silicon carbide’s high thermal conductivity dissipates heat quickly, reducing tool wear but requiring more aggressive cooling. Zirconia, with its higher toughness, is more forgiving during machining than alumina but demands sharper tools to avoid surface damage.

Applications of CNC Ceramics: Where Precision Meets Performance

The unique properties of CNC-machined ceramics make them indispensable across industries. Here are some standout use cases:

- Aerospace components: Turbine blades and heat shields made from silicon carbide withstand temperatures exceeding 1,200°C, outperforming metal alternatives in jet engines. CNC machining ensures the intricate cooling channels in these parts maintain precise dimensions for optimal airflow.

- Medical implants: Zirconia ceramics, prized for their biocompatibility and strength, are CNC-machined into hip and knee replacements. The ability to achieve mirror-like surface finishes reduces friction and wear, extending implant lifespans by up to 15 years compared to traditional materials.

- Electronics: Alumina ceramic substrates, machined with precision machining techniques, provide insulation and heat dissipation for circuit boards in high-power devices. Tolerances as tight as ±0.01 mm ensure perfect alignment with sensitive electronic components.

- Automotive parts: Ceramic valve guides and pistons, machined to resist corrosion and high temperatures, improve engine efficiency. A leading auto manufacturer reported a 12% reduction in fuel consumption after switching to CNC-machined ceramic parts.

Tools and Techniques in CNC Ceramic Processing: Overcoming Hardness

Machining ceramics requires tools and techniques that can handle extreme hardness without compromising precision. Here’s what works:

- Diamond tools: Polycrystalline diamond (PCD) tools are the gold standard for ceramic machining. Their hardness (90–95 HRC) allows them to cut through even the toughest ceramics, though they come at a premium—costing 3–5 times more than carbide tools. However, their longer lifespan (up to 50 times that of carbide) often justifies the investment.

- Ultrasonic machining: This technique combines mechanical cutting with high-frequency vibrations (20–40 kHz), reducing cutting forces by up to 70%. It’s particularly effective for brittle ceramics like alumina, minimizing chipping in delicate features.

- Laser machining: For microscale features (e.g., 0.01 mm holes in electronic components), lasers offer non-contact precision. They’re ideal for ceramics that are sensitive to mechanical stress, though they can leave a heat-affected zone (HAZ) that requires post-processing.

- Cooling strategies: Cutting fluids with high lubricity (like synthetic oils) reduce friction and heat buildup. Mist cooling systems, which deliver a fine spray of fluid, are more effective than flood cooling for ceramics, as they prevent thermal shock.

Advantages and Challenges of CNC Ceramics: Balancing the Scales

Like any technology, CNC ceramics come with trade-offs. Understanding them helps you make informed decisions:

Advantages:

- High precision: CNC machining achieves tolerances as tight as ±0.005 mm, critical for applications like medical devices and aerospace components.

- Durability: Ceramics resist corrosion, wear, and high temperatures, outlasting metals in harsh environments. For example, ceramic pump parts in chemical plants last 3–4 times longer than stainless steel equivalents.

- Corrosion resistance: Unlike metals, ceramics don’t react with acids, bases, or saltwater—making them ideal for marine and chemical processing applications.

Challenges:

- High cost: From materials to specialized tools, CNC ceramic machining can cost 2–3 times more than metal machining. However, the longer part lifespan often offsets this over time.

- Fragility: Ceramics are prone to cracking under sudden stress, requiring careful handling and machining. This increases scrap rates by 5–10% compared to metal projects.

- Machining complexity: Achieving tight tolerances demands skilled operators and advanced software. A survey of manufacturers found that 40% struggle with toolpath optimization for ceramics.

Yigu Technology’s Perspective: Elevating CNC Ceramic Manufacturing

As a leading custom manufacturing supplier in China, Yigu Technology understands the nuances of CNC ceramics. We’ve invested in state-of-the-art diamond tooling and ultrasonic machining centers to tackle even the most challenging projects. Our engineers specialize in optimizing toolpaths for ceramic composites and zirconia, ensuring precision while minimizing waste. Whether you need aerospace components or medical implants, we combine material expertise with technical skill to deliver parts that meet your exact specifications—on time and within budget.

FAQs

- What is the typical lead time for CNC-machined ceramic parts?

Lead times vary by complexity, but most parts take 2–4 weeks. Simple components (e.g., alumina washers) can be produced in as little as 5 days, while intricate aerospace parts may require 6–8 weeks.

- Can CNC machining handle all types of ceramics?

Most technical ceramics (alumina, zirconia, silicon carbide) are machinable with CNC, but some ultra-hard materials (e.g., boron carbide) may require specialized techniques like electrical discharge machining (EDM).

- How do I reduce the cost of CNC ceramic machining?

Design for manufacturability (DFM) is key. Simplifying geometries, avoiding sharp corners, and using standard tolerances where possible can lower costs by 15–20%. Additionally, batch production reduces per-unit costs significantly.