Key Considerations for Ensuring Precision in Machined Parts

Introduction to Machined Parts

Definition and Importance

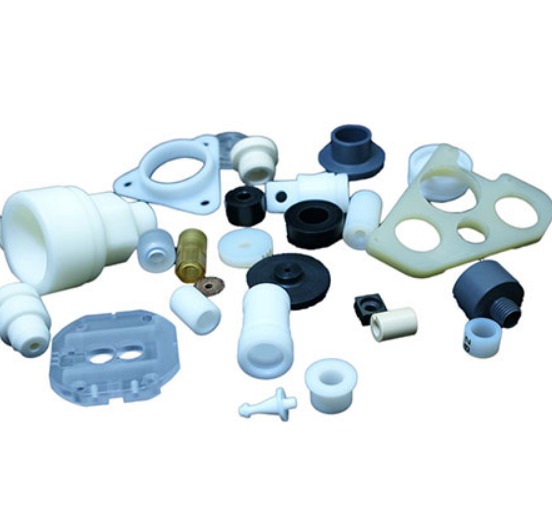

Machined parts are components that are created through various machining processes, such as milling, turning, drilling, grinding, and more. The primary goal of machining is to transform raw materials (often metal or plastic) into components that meet specific, precise dimensions and tolerances. These parts are crucial to the functionality and reliability of end products, particularly in industries like aerospace, automotive, medical devices, and electronics, where even slight deviations can lead to malfunction or failure.

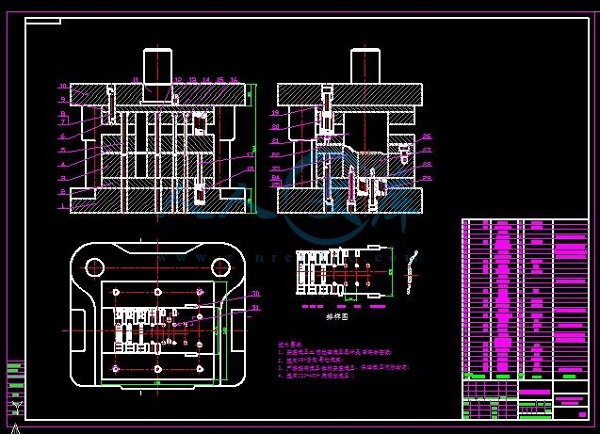

Types of Machined Parts

Machined parts can generally be categorized into the following types:

- Rotational Parts: Includes shafts, gears, pulleys, and spindles, typically produced using lathe operations.

- Prismatic Parts: Includes plates, blocks, and parts with flat surfaces, generally machined on milling machines.

- Specialized Parts: Custom-made components designed for specific applications, such as those in the aerospace, medical, or defense industries.

Material Selection

Properties and Specifications

Choosing the right material is critical for the success of any machining project. The material’s properties will affect the machining process, the tools used, and the finished part’s functionality. Key material properties to consider include:

- Strength and Durability: The material must be strong enough to withstand operational stresses, whether from load-bearing, vibration, or temperature.

- Machinability: Some materials are easier to machine due to their hardness, brittleness, or tendency to work-harden. For instance, aluminum is generally easier to machine than titanium.

- Thermal Conductivity: Essential for parts involved in heat transfer, such as engine components or heat exchangers.

- Corrosion Resistance: Important for parts exposed to harsh environments, like marine components or medical implants.

Impact on Machining

The material selected dictates which machining processes are appropriate and which tools should be used. For example, titanium and stainless steel are more challenging to machine compared to aluminum due to their hardness and tendency to cause rapid tool wear. These materials may require specialized cutting tools, slower feed rates, and higher cutting temperatures.

Machining Processes

Traditional vs. Modern Techniques

- Traditional Techniques: Methods like manual milling, turning, and drilling rely heavily on the operator’s skill and experience. These are often used for low-volume production or simpler geometries.

- Modern Techniques: CNC (Computer Numerical Control) machines automate the machining process, increasing precision, repeatability, and efficiency. Modern techniques also include laser cutting, waterjet cutting, and 3D printing, which offer additional flexibility for complex geometries and materials.

Process Selection Criteria

Choosing the right machining process depends on several factors:

- Part Complexity: Simple parts may only need basic milling or turning, while complex geometries require advanced techniques like multi-axis CNC machining or EDM (Electrical Discharge Machining).

- Volume: High-volume production often benefits from automation (e.g., CNC milling or turning), while low-volume or prototype parts may be better suited to manual machining or rapid prototyping technologies like 3D printing.

- Material: The machinability of the material dictates which process is best. Stainless steel may require slow speeds and careful tool choice, while aluminum can be processed at higher speeds with more basic tools.

- Tolerances: High-precision parts with tight tolerances (e.g., aerospace or medical) require advanced CNC machines capable of micron-level accuracy, while parts with looser tolerances can be produced using less expensive, less precise methods.

Tolerances and Specifications

Importance of Tolerances

Tolerances define the acceptable range of variation in a part’s dimensions and are crucial for ensuring that parts fit together properly, function as intended, and meet safety or performance standards. Even small deviations in dimensions or geometry can lead to significant issues in high-performance applications, such as aerospace, automotive, and medical devices.

Setting Tolerances for Precision

Setting proper tolerances involves understanding the functional requirements of the part, the capabilities of the machining process, and the impact of tighter tolerances on cost:

- Tighter Tolerances: Necessary for critical applications like aerospace or medical implants, where precision is paramount. However, tighter tolerances often increase manufacturing costs and production time.

- Looser Tolerances: More suitable for non-critical components, which can reduce costs but may affect part performance and interoperability.

Tolerances should be realistic given the machining method and material. For instance, achieving a tolerance of ±0.001 mm on a high-precision CNC machine may be feasible, while the same tolerance on manual machines could be extremely difficult or impossible to achieve.

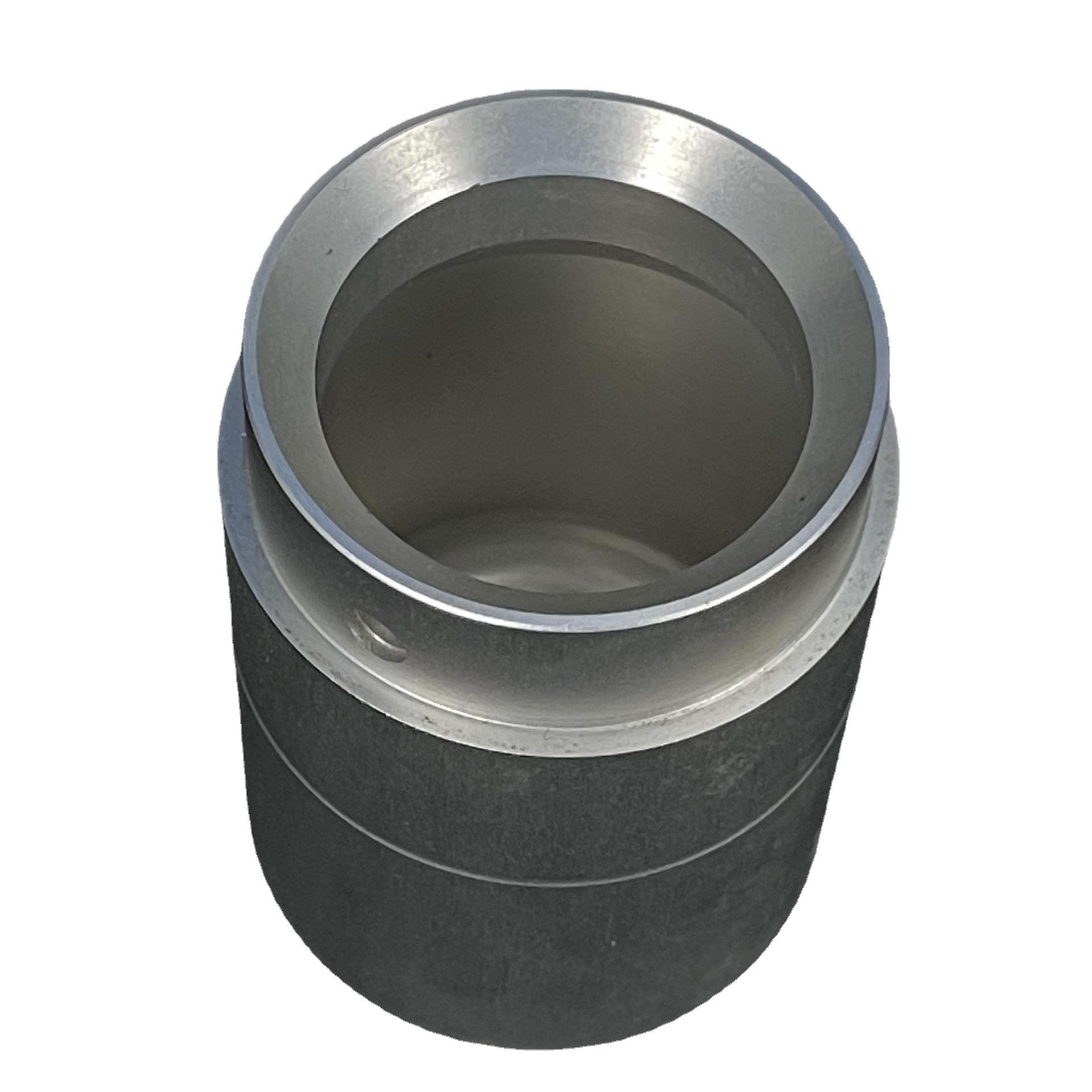

Surface Finish

Finishing Techniques

Surface finish refers to the texture or smoothness of a part’s surface, which impacts both its aesthetic appearance and functional performance. Some key finishing techniques include:

- Polishing: Achieves a smooth, shiny finish, commonly used for cosmetic components or parts that require low friction.

- Anodizing: Used for aluminum parts to improve corrosion resistance and enhance their appearance.

- Plating: Adds a layer of metal (e.g., gold, nickel) to the surface to improve durability, conductivity, or aesthetic quality.

- Sandblasting: Provides a matte finish, often used for pre-coating treatments or to improve adhesion for subsequent coatings.

Surface Finish Standards

Surface finish is often measured using parameters like Ra (Roughness Average) and Rz (Maximum Height of the Profile). These values define the level of smoothness required for different applications:

- For example, a highly polished surface with an Ra value of less than 1 micron may be required for medical implants or precision optics.

- A rougher finish with an Ra of several microns may be acceptable for industrial machinery parts.

Conclusion

Recap of Key Considerations

Ensuring precision in machined parts involves multiple factors that must be carefully considered:

- Material Selection: Materials must balance strength, machinability, and other properties like corrosion resistance and thermal conductivity.

- Machining Processes: The right process must be chosen based on part complexity, volume, material, and tolerance requirements.

- Tolerances: Properly set tolerances are critical for functionality, especially in industries like aerospace, automotive, and medical devices.

- Surface Finish: The appropriate surface finish ensures both the performance and aesthetic quality of the part.

Best Practices for Precision Machining

To achieve high precision in machined parts:

- Use Advanced Equipment: CNC machines, multi-axis systems, and modern automation technologies are essential for precision.

- Regular Calibration: All machines should be regularly calibrated to maintain consistent accuracy.

- Skilled Workforce: Investing in training for machinists and engineers ensures adherence to best practices and new technological developments.

- Quality Control: Implement rigorous quality control checks throughout the process, including dimensional inspections, surface roughness measurements, and functional testing.

FAQs

1. What is the role of tolerance in machined parts?

Tolerances define the acceptable variation in dimensions and ensure that parts fit together and function as intended. Properly set tolerances are crucial for performance, reliability, and safety, especially in high-performance industries like aerospace and medical manufacturing.

2. How do different materials affect the machining process?

Different materials vary in hardness, machinability, and thermal properties. Harder materials like titanium may require slower feed rates and specialized tools, while softer materials like aluminum can be machined faster with standard tools. The material affects the choice of cutting speed, tool type, and cooling methods.

3. Why is surface finish important for machined parts?

Surface finish affects both the aesthetic appearance and functional performance of machined parts. A smoother surface can reduce friction, improve wear resistance, and enhance overall part durability. It also contributes to coating adhesion and corrosion resistance in certain applications, such as medical implants or aerospace components.