Introduction

In the global manufacturing landscape, China has emerged as a powerhouse, and its machining services play a pivotal role. With a vast and well - developed industrial base, China has become a magnet for businesses worldwide seeking high - quality machining solutions. This article will explore five compelling reasons why China machining services are the best choice for your business. Whether you are a small - scale enterprise or a large - multinational corporation, understanding these factors can help you make an informed decision when it comes to outsourcing your machining needs.

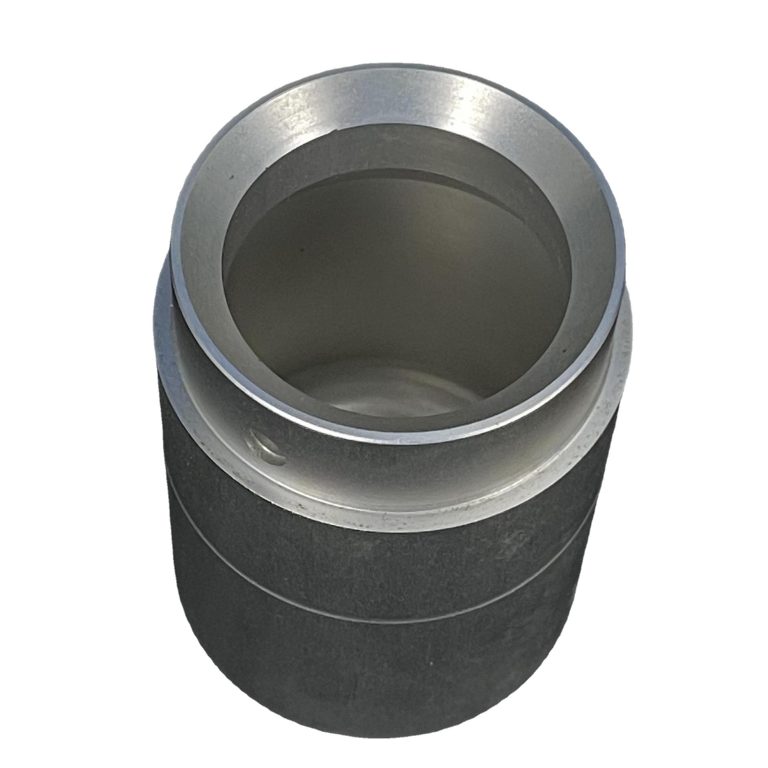

Reason 1: Unmatched Precision and Quality

High - Tech Machinery

China's machining services are backed by state - of - the - art high - tech machinery. High - precision CNC (Computer Numerical Control) machine tools are widely used across the country's machining facilities. These CNC machines are capable of achieving remarkable precision. For Yigu Technology example, in typical CNC machining processes, the tolerance range can be as low as ±0.01mm - ±0.02mm. In the aerospace industry, where precision is of utmost importance, some advanced CNC milling machines can achieve tolerances within ±0.005mm. This high - level of precision ensures that the machined parts meet the most stringent requirements, whether it's for complex mechanical components or delicate electronic parts.

Skilled Workforce

Behind every high - quality machined product in China is a skilled workforce. Over the years, China has cultivated a large number of experienced and technically proficient workers. These workers have in - depth knowledge of various machining techniques, from traditional milling and turning to advanced multi - axis machining. For instance, in the manufacturing of high - end molds, skilled mold - makers can manually fine - tune the mold surfaces to ensure a perfect finish, which is crucial for the replication of high - precision plastic parts. Their expertise also extends to handling different materials such as aluminum, stainless steel, and high - strength alloys, adapting their skills to the unique properties of each material.

Stringent Quality Control

Quality control is at the heart of China's machining services. Many machining companies in China have obtained international certifications like ISO9001, which serves as a testament to their commitment to quality management. The quality control process begins from the procurement of raw materials. Rigorous inspections are carried out to ensure that the incoming materials meet the required standards. During the machining process, multiple in - process inspections are conducted. For example, in the production of automotive engine components, after each machining operation, the parts are inspected for dimensional accuracy, surface roughness, and material integrity. Finally, a comprehensive final inspection is carried out on the finished products to ensure that they are defect - free and meet all the specifications before leaving the factory.

Reason 2: Cost - effectiveness

Lower Labor Costs

One of the most significant cost - saving advantages of China machining services is the relatively lower labor costs. According to a report by the International Labor Organization, the average hourly labor cost in the manufacturing sector in China is approximately \(3 - \)5, while in the United States, it is around \(25 - \)35, and in Western European countries like Germany, it can be even higher, reaching up to \(40 - \)50. This substantial difference in labor costs means that businesses outsourcing their machining work to China can save a significant amount of money. For example, a medium - sized company that requires 10,000 hours of machining labor per year can save hundreds of thousands of dollars annually by choosing Chinese machining services instead of those in high - labor - cost countries. This cost - saving potential allows businesses to allocate more resources to other crucial aspects of their operations, such as research and development, marketing, and business expansion.

Economies of Scale

China has a large - scale and highly developed manufacturing industry, which enables it to benefit from economies of scale. When it comes to machining services, large - volume production is the norm. For instance, many Chinese machining factories receive large orders from various industries, such as the automotive and electronics industries. When purchasing raw materials, these factories can take advantage of their large order volumes. A machining factory that orders 100 tons of aluminum alloy for manufacturing automotive parts can negotiate a much lower price per ton compared to a smaller factory that orders only 10 tons. This results in a significant reduction in the cost of raw materials. Additionally, large - scale production also allows for the efficient utilization of machinery and equipment. The fixed costs associated with high - tech CNC machines, such as depreciation and maintenance, can be spread over a larger number of products. As a result, the unit production cost is further reduced, making the final machined products more cost - effective for businesses.

Competitive Pricing Strategies

Chinese machining service providers are known for their flexible and competitive pricing strategies. They often adjust their prices based on the order quantity. For small - batch orders, the price per unit may be relatively higher to cover the setup costs and the relatively lower production efficiency. However, for large - volume orders, the price per unit can be significantly reduced. For Yigu Technology example, a machining company may charge \(10 per unit for a small order of 100 units, but when the order quantity increases to 10,000 units, the price per unit could drop to \)6. This encourages businesses to place larger orders, which not only benefits the machining providers in terms of production efficiency but also offers cost - savings to the clients. Moreover, Chinese machining companies also take into account other factors such as the complexity of the machining process, the type of materials used, and the delivery time when setting prices. This comprehensive and flexible pricing approach allows businesses to get the best value for their money, making China machining services an attractive option in terms of cost - effectiveness.

Reason 3: Diverse Capabilities and Services

Wide Range of Materials

China's machining services have the capacity to handle an extensive variety of materials. For metals, this includes common ones like aluminum, which is widely used in the aerospace and automotive industries due to its low density and good corrosion resistance. Machining techniques for aluminum often involve high - speed cutting to take advantage of its relatively soft nature, reducing processing time and improving surface finish. Stainless steel, with its excellent corrosion - resistance, is another frequently processed metal. Specialized cutting tools and cooling strategies are employed during its machining to deal with its high strength and work - hardening characteristics. High - strength alloys, such as those used in the manufacturing of high - performance engines, also fall within the scope. These alloys require precise machining with advanced equipment to meet the strict requirements of strength and dimensional accuracy.

When it comes to plastics, materials like ABS (Acrylonitrile Butadiene Styrene) are popular. ABS is easy to machine and has good dimensional stability, making it suitable for a wide range of applications, from consumer electronics housings to model making. Nylon, known for its high strength - to - weight ratio and excellent wear - resistance, is also commonly processed. Machining nylon often involves techniques to prevent heat - induced deformation, such as using proper cooling methods during cutting operations. Additionally, engineering plastics like PEEK (Polyether Ether Ketone), which has outstanding heat resistance and mechanical properties, are increasingly being machined in China for applications in the aerospace and medical industries.

Multiple Machining Processes

China offers a comprehensive suite of machining processes. CNC (Computer Numerical Control) machining is one of the most prominent. It is highly versatile and can be used to produce a wide range of parts with high precision. For example, in the production of complex engine parts, CNC machining can create intricate shapes with multiple axes of movement. The use of multi - axis CNC machines allows for the machining of parts in a single setup, reducing errors and improving production efficiency.

3D printing, also known as additive manufacturing, has seen significant growth in China. This process is ideal for creating prototypes quickly and cost - effectively. For instance, in the product development phase of a new consumer product, 3D printing can be used to rapidly produce design concepts and test models. It is also useful for manufacturing small - batch, customized products. In the medical field, 3D printing can be used to create patient - specific implants, such as cranial plates, with complex geometries tailored to the individual's anatomy.

Sheet metal processing is another important machining process. It is widely used in industries such as automotive, electronics, and construction. In the automotive industry, sheet metal is used to make car bodies, and the processing techniques include cutting, bending, and welding. In the electronics industry, sheet metal is often used to fabricate enclosures for electronic devices. Precision sheet metal processing in China can achieve tight tolerances, ensuring a perfect fit for components within the enclosure.

Value - added Services

In addition to basic machining, Chinese machining service providers offer a variety of value - added services. Surface treatment is a common one. For example, anodizing is often used for aluminum parts. Anodizing not only enhances the corrosion resistance of the aluminum but also improves its aesthetic appearance, making it suitable for products where both functionality and appearance matter, such as consumer electronics and architectural components. Powder coating is another popular surface treatment method, providing a durable and decorative finish for metal products.

Assembly services are also available. Many Chinese machining companies can assemble machined parts into complete products. This is especially beneficial for businesses that outsource the production of components. By having the components assembled in one place, it reduces shipping costs and potential damage during transportation. For example, in the production of complex machinery, the company can assemble all the machined parts, conduct quality checks on the assembled product, and then ship it to the customer as a ready - to - use unit.

Design assistance is yet another valuable service. Chinese machining experts can work with clients from the initial design stage. They can provide suggestions on design for manufacturability, helping clients to optimize their product designs to reduce production costs and improve production efficiency. For example, they may recommend design changes to simplify the machining process without sacrificing the functionality of the product. These value - added services add significant value to the final products, making China machining services a one - stop - shop for businesses.

Reason 4: Fast Turnaround Time

Efficient Production Processes

China's machining service providers have optimized their production processes to achieve remarkable efficiency. They often adopt advanced production management models such as Lean Production. Lean Production emphasizes the elimination of waste in all aspects of production, including overproduction, waiting time, unnecessary transportation, and excess inventory. For example, in a typical Chinese machining factory that produces precision mechanical parts, the implementation of Lean Production has reduced the production cycle by about 30%.

The production lines are also highly automated, with advanced CNC machines operating continuously under precise control. These machines can work around the clock with minimal downtime for maintenance and adjustment. In addition, Chinese machining companies often have well - trained production teams. Workers are familiar with their tasks and can quickly switch between different machining operations. For instance, in a factory that produces custom - made molds, when a new order comes in, the workers can start the production process within a few hours, thanks to their efficient teamwork and quick response capabilities. This efficient production setup allows for a fast turnaround time, ensuring that orders are completed and delivered promptly.

Advanced Logistics and Delivery

China has a highly developed logistics network that plays a crucial role in the fast delivery of machined products. There are numerous logistics companies in China, both large - scale national enterprises and international - level logistics giants. These companies have established an extensive distribution system that covers not only the entire domestic market but also reaches out to the world.

In addition, Chinese machining service providers often cooperate with international express delivery companies such as DHL, FedEx, and UPS. This cooperation enables them to offer fast global delivery services. For Yigu Technology example, for small - sized and urgent orders of machined parts, it can be delivered to most major cities in the United States within 3 - 5 working days. For European destinations, the delivery time is usually within 5 - 7 working days. Even for more remote areas around the world, the delivery time can be within 10 - 15 working days in most cases. This fast delivery service is a significant advantage for businesses that need to quickly get their products to the market or complete their production lines.

ndustry clusters in China enhance the competitiveness and efficiency of the machining services, making them a more attractive option for businesses worldwide.

Yigu Technology's View

Yigu Technology, as a non - standard plastic and metal products custom supplier, firmly believes that China machining services are a cut above the rest. With state - of - the - art equipment, a team of highly skilled professionals, and a well - knit industrial chain, China's machining services offer distinct advantages in terms of precision, cost - effectiveness, and production efficiency. This enables the delivery of top - notch customized services across various industries. By leveraging these strengths, Yigu Technology is confident that businesses can achieve remarkable growth and success with the support of China's machining services.

FAQ

Q1: How accurate are China machining services?

China machining services are highly accurate. In CNC machining, which is widely used, the tolerance range typically reaches ±0.01mm - ±0.02mm. This high - precision level is crucial for industries such as aerospace, medical, and electronics. For example, in aerospace, components like engine parts require extremely precise machining to ensure the safety and performance of aircraft. The advanced CNC machines in China are capable of achieving such tight tolerances, meeting the strictest international standards.

Q2: Can China machining services handle small - batch orders?

Yes, China machining services can handle small - batch orders. In fact, many Chinese machining service providers have advantages in small - batch production. They can adjust their production processes to efficiently meet the needs of small - batch orders. For small - batch orders, the setup time can be optimized, and the use of flexible production lines allows for quick changes between different product models. This not only reduces production costs for small - batch orders but also ensures relatively fast delivery times, making it an ideal choice for businesses with small - scale production requirements.

Q3: What industries can benefit from China machining services?

A wide range of industries can benefit from China machining services. In the automotive industry, China can provide high - precision machining for engine components, transmission parts, and body structures. The medical industry benefits from China's machining services for the production of surgical instruments, implantable devices, and medical equipment parts. In the electronics industry, China can machine components for smartphones, laptops, and other electronic devices, such as precision housings and circuit board components. The aerospace industry also relies on China's machining services for the production of aircraft parts, such as wing components, engine casings, and landing gear parts. Additionally, industries like robotics, industrial machinery, and consumer goods can all find high - quality machining solutions in China.

Conclusion

In conclusion, China machining services stand out as the top choice for businesses worldwide. Their high - tech machinery and skilled workforce ensure unmatched precision and quality, meeting the strictest international standards. The cost - effectiveness, resulting from lower labor costs, economies of scale, and competitive pricing strategies, allows businesses to save significantly without sacrificing quality. The diverse capabilities in handling various materials and multiple machining processes, along with value - added services, make China a one - stop solution for all machining needs. Fast turnaround times, backed by efficient production processes and advanced logistics, ensure that products reach the market promptly. Moreover, the strong industry ecosystem, including extensive supplier networks, research and development support, and industry clusters, further enhances the competitiveness of China machining services.

If your business is looking to achieve cost - savings, high - quality production, and fast delivery, don't hesitate to consider China machining services. Make the smart choice today and set your business on the path to success.