What is SLS 3D Systems?

Definition and Basic Principle

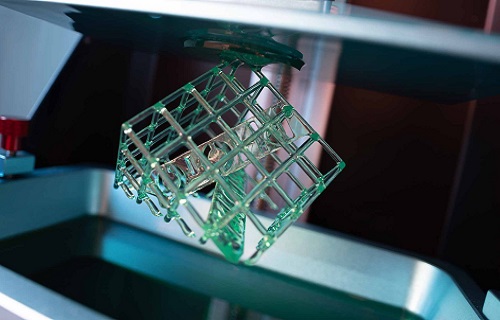

SLS 3D Systems, short for Selective Laser Sintering 3D Systems, is a revolutionary additive manufacturing technology. It operates on the principle of using a high - power laser, typically a CO₂ laser, to selectively sinter powdered materials layer by layer. The process begins with a digital 3D model, which is sliced into thin cross - sectional layers by specialized software.

These cross - sectional data are then sent to the SLS 3D printer. Inside the printer, a powder bed is filled with a layer of powdered material, such as plastic, metal, or ceramic powder. The laser scans the surface of the powder bed according to the cross - sectional shape of the model for that layer. As the laser beam hits the powder, it raises the temperature of the powder particles to their melting or sintering point, causing them to bond together. Once one layer is completed, a new layer of powder is spread over the previously sintered layer, and the process repeats until the entire 3D object is formed. This layer - by - layer construction method allows for the creation of complex geometries that are difficult or impossible to achieve with traditional manufacturing techniques.

Key Components

- Laser Source: The laser is the heart of the SLS 3D system. For example, in many industrial - grade SLS printers, a high - power CO₂ laser with wavelengths around 10.6 μm is used. The power of the laser can range from several watts to hundreds of watts, depending on the application and the type of material being processed. A higher - power laser can sinter materials more quickly, but it also requires more careful control to ensure accurate and consistent results.

- Powder Bed: The powder bed is where the magic happens. It holds the powdered material and provides a flat surface for the laser to sinter. The powder bed is typically made of a heat - resistant material and is equipped with a mechanism to evenly spread a new layer of powder after each sintering step. For instance, some powder beds use a roller or a blade to spread the powder to a precise thickness, usually in the range of 0.05 - 0.2 mm per layer.

- Scanning System: The scanning system, often composed of galvanometric mirrors and a lens, is responsible for directing the laser beam accurately across the powder bed. These mirrors can quickly change the direction of the laser beam, allowing it to trace the complex 2D shapes of each cross - section. The scanning speed can be very high, sometimes reaching thousands of points per second, enabling fast and efficient sintering of each layer.

- Control System: This is like the brain of the SLS 3D system. It controls all the components, including the laser power, scanning speed, powder spreading, and temperature control. The control system reads the 3D model data, slices it into layers, and sends the appropriate instructions to the other components to ensure that the 3D object is printed accurately.

Applications of SLS 3D Systems

SLS 3D systems have found widespread applications across various industries due to their unique capabilities in creating complex geometries and producing customized parts. Here are some of the key application areas:

In the Automotive Industry

In the automotive industry, SLS 3D systems are used for a variety of purposes. One of the main applications is the production of automotive part prototypes. For example, engine components, interior parts like dashboard prototypes, and exterior body panels can be created quickly and cost - effectively.

Let's take a look at a comparison between traditional manufacturing and SLS 3D printing for producing 100 pieces of a small, complex automotive part in terms of cost and production cycle:

| Aspect | Traditional Manufacturing | SLS 3D Printing |

| Cost (USD) | - Mold cost: 10,000 - 30,000 - Material cost per piece: 5 - Labor cost: 2,000 - Total: 17,000 - 37,000 | - Material cost per piece: 20 - Labor cost (less intensive): 500 - Total: 2,500 |

| Production Cycle | 4 - 8 weeks (including mold design, production, and trial runs) | 1 - 2 weeks (including design modification time if needed) |

This table clearly shows that for small - batch production of complex parts, SLS 3D printing is more cost - effective and time - efficient. It also allows for rapid design iteration, which is crucial in the automotive industry where new models are constantly being developed.

In Aerospace and Defense

In the aerospace and defense sectors, SLS 3D systems play a vital role in manufacturing components with complex geometries. For instance, parts of aircraft engines, such as turbine blades and fuel nozzles, can be produced using SLS technology. These components often require complex internal cooling channels and lightweight lattice structures to improve performance.

A study showed that by using SLS 3D - printed titanium alloy components in an aircraft engine, the weight of the engine was reduced by about 15%, which led to a 10% increase in fuel efficiency. This is because SLS 3D printing allows for the creation of optimized, lightweight structures that are not possible with traditional manufacturing methods. In the defense industry, SLS 3D systems are used to produce customized parts for military vehicles and weapons, enabling faster production and better adaptation to specific mission requirements.

In Healthcare and Medical Field

The healthcare and medical field have also benefited greatly from SLS 3D systems. One of the most significant applications is the creation of customized medical implants. For example, hip implants can be 3D - printed using SLS technology to perfectly match the patient's unique anatomy. A case study in a major hospital found that patients who received SLS 3D - printed hip implants had a 30% shorter recovery time compared to those with traditional implants. This is because the customized implants fit better, reducing the risk of complications and promoting faster osseointegration.

SLS 3D systems are also used to produce anatomical models for surgical planning. Surgeons can use these accurate 3D - printed models to practice complex procedures before operating on patients, leading to more successful surgeries and better patient outcomes.

Yigu Technology's View

As a non - standard plastic metal products custom supplier, Yigu Technology highly values the development of SLS 3D Systems. SLS 3D Systems has brought new opportunities to our business. The ability to create complex geometries allows us to produce custom - designed plastic and metal products that meet the unique needs of our customers more precisely. For example, when manufacturing some complex - shaped plastic connectors, SLS 3D Systems enables us to produce parts with internal cavities and intricate structures in one - step, reducing the need for multi - process assembly as in traditional manufacturing.

In terms of the future, we believe that SLS 3D Systems will continue to evolve. The development of new materials compatible with SLS technology will expand its application scope. We are looking forward to more efficient SLS 3D printing processes, which will further shorten production cycles and reduce costs. This will enable us to provide faster and more cost - effective services to our customers, and also promote the continuous innovation and development of the non - standard plastic metal products industry.

FAQ

What types of materials can be used in SLS 3D Systems?

Common materials used in SLS 3D systems include plastics like nylon (such as nylon 11 and nylon 12), which are popular for their good mechanical properties, toughness, and heat resistance. Metal powders such as titanium, aluminum, and stainless - steel can also be used, enabling the production of high - strength and heat - resistant parts. Additionally, ceramic powders are suitable for applications requiring high - temperature resistance and chemical stability. Some composite powders, which combine different materials to achieve unique properties, are also emerging in SLS 3D printing.

Is SLS 3D printing suitable for large - scale production?

SLS 3D printing has certain advantages for large - scale production. It can produce complex parts without the need for expensive molds, which reduces upfront costs. For example, in the production of small - batch complex automotive parts, SLS 3D printing is more cost - effective than traditional manufacturing. However, its production speed is relatively slower compared to some traditional mass - production methods like injection molding. Also, the cost of materials and equipment in SLS 3D printing can be high. So, for extremely large - scale production with high - volume and simple - shaped parts, traditional methods may still be more suitable. But for mid - scale production of complex and customized parts, SLS 3D printing can be a viable option.

How much does an SLS 3D printing system cost?

The cost of an SLS 3D printing system can vary widely. Entry - level SLS 3D printers may start at around $5000. However, industrial - grade SLS 3D printing systems, which offer higher precision, larger build volumes, and better - quality output, can cost hundreds of thousands of dollars. Factors that affect the price include the build volume (larger build volumes are more expensive), the power and quality of the laser source, the accuracy and speed of the scanning system, and additional features like automated powder handling systems.