Introduction

Definition and Basics

Powder bed fusion additive manufacturing, also known as powder bed fusion 3D printing, is a revolutionary manufacturing technology within the realm of additive manufacturing. It involves the selective melting or sintering of powdered materials, layer by layer, to create three - dimensional objects based on a digital model.

The basic principle is as follows: First, a thin layer of powder material, which can be metal, ceramic, or polymer powder, is evenly spread across a build platform. Then, a high - energy source, such as a laser or an electron beam, selectively scans the powder layer according to the cross - sectional data of the 3D model. The energy source melts or sinters the powder in the scanned areas, fusing the powder particles together to form a solid layer. After the completion of one layer, the build platform is lowered by a certain thickness (usually in the range of tens of micrometers), a new layer of powder is spread, and the process is repeated until the entire 3D object is fabricated.

For example, in laser powder bed fusion (LPBF), a high - power laser is used as the energy source. The laser beam can be precisely controlled to have a small spot size, typically in the range of 50 - 100 micrometers. This allows for high - resolution melting of the powder, enabling the creation of complex geometries with fine details. In electron beam powder bed fusion (EBPF), an electron beam is used instead. The electron beam can penetrate deeper into the powder, which is beneficial for processing certain materials and achieving high - density parts.

Powder bed fusion additive manufacturing holds a significant position in the field of additive manufacturing. It accounts for a large share of the industrial 3D printing market. According to a report by Wohlers Associates, in 2022, powder bed fusion technologies were widely used in industries such as aerospace, automotive, and healthcare. In the aerospace industry, for instance, about 40% of the 3D - printed parts were produced using powder bed fusion additive manufacturing. This is because it can produce complex and lightweight components with high strength - to - weight ratios, which are crucial for reducing fuel consumption and improving the performance of aircraft.

Different Energy Sources in PBF

The performance and application scope of powder bed fusion additive manufacturing are highly dependent on the energy sources used. The main energy sources include lasers, electron beams, and infrared light, each with its own unique characteristics and applications.

Laser - Based PBF (PBF - LB)

Laser - based powder bed fusion (PBF - LB), also known as selective laser melting (SLM) or selective laser sintering (SLS), is one of the most widely used PBF technologies. In this process, a high - power laser is used as the energy source. The laser beam scans the powder bed according to the cross - sectional data of the 3D model, melting or sintering the powder in the scanned areas.

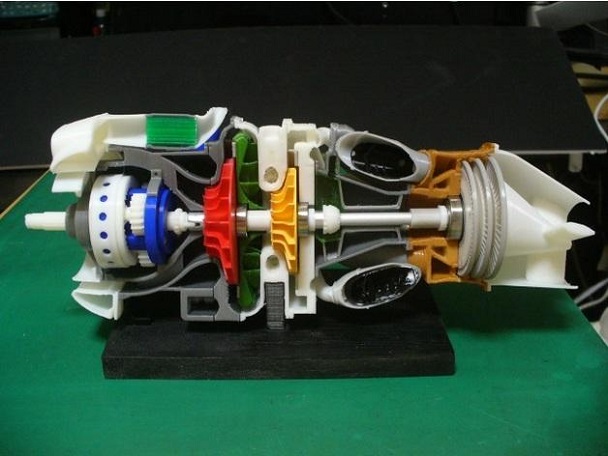

Lasers offer high energy density and precise control. The spot size of the laser beam can be as small as tens of micrometers, enabling the fabrication of parts with high precision and fine details. For example, in the aerospace industry, PBF - LB is used to manufacture complex components such as turbine blades. These turbine blades often have intricate internal cooling channels and aerodynamic shapes. A study by Airbus showed that PBF - LB technology can reduce the weight of turbine blades by up to 30% compared to traditional manufacturing methods, while maintaining the same or even better mechanical properties. This weight reduction significantly improves the fuel efficiency of aircraft engines. In the medical field, PBF - LB is also used to produce customized implants. These implants can be designed to fit the unique anatomy of each patient, improving the success rate of surgeries.

Electron Beam - Based PBF (PBF - EB)

Electron beam - based powder bed fusion (PBF - EB), or electron beam melting (EBM), uses an electron beam as the energy source. The electron beam is generated in a vacuum environment, and when it hits the powder bed, it transfers its kinetic energy to the powder particles, causing them to melt and fuse together.

Compared with laser - based PBF, PBF - EB has some distinct differences. The electron beam can penetrate deeper into the powder, which allows for faster processing speeds and the ability to process thicker layers of powder. For example, in the manufacturing of large - scale metal components in the aerospace and automotive industries, PBF - EB can be more efficient. It is also suitable for materials that are difficult to process with lasers, such as some reactive metals like titanium and its alloys. Since the process occurs in a vacuum, it reduces the risk of oxidation and contamination during the melting process. For instance, in the production of titanium alloy aerospace components, PBF - EB ensures high - quality, contamination - free parts. However, the equipment for PBF - EB is more complex and expensive due to the need for a vacuum system and electron - beam - generating components.

Infrared Light - Based PBF (PBF - IrL)

Infrared light - based powder bed fusion (PBF - IrL) uses infrared light as the energy source to heat and sinter the powder materials. Infrared light has the advantage of being able to uniformly heat the powder bed over a relatively large area.

The principle of PBF - IrL is that the infrared light is absorbed by the powder particles, and the energy is converted into heat, causing the powder to reach the sintering temperature and bond together. This method is often used for materials that are sensitive to high - energy density sources like lasers or electron beams, such as some polymers and certain ceramic powders. For example, in the production of polymer - based functional parts, PBF - IrL can provide a more gentle heating process, reducing the risk of thermal degradation of the polymer materials. It is also suitable for applications where a large - scale, low - cost manufacturing of parts with relatively simple geometries is required, as the equipment for PBF - IrL is generally less complex and costly compared to laser - or electron - beam - based systems.

Materials Used in PBF

Metal Powders

A variety of metal powders are commonly used in powder bed fusion additive manufacturing, each with its own set of properties and applications.

Titanium and its alloys, such as Ti - 6Al - 4V, are widely used in the aerospace and medical industries. Titanium alloys offer an excellent strength - to - weight ratio, high corrosion resistance, and good biocompatibility. For example, in the aerospace industry, components made from Ti - 6Al - 4V using PBF can reduce the weight of parts by up to 40% compared to traditional manufacturing methods, while maintaining high strength. This weight reduction directly contributes to fuel savings and increased aircraft performance. In the medical field, titanium alloy implants produced by PBF can better integrate with the human body due to their biocompatibility, reducing the risk of rejection.

Stainless steels, like 316L, are popular in applications that require good corrosion resistance and mechanical properties. They are often used in the food and beverage, chemical, and marine industries. 316L stainless steel parts fabricated by PBF have a yield strength of around 205 - 275 MPa and an ultimate tensile strength of 485 - 655 MPa. These mechanical properties make them suitable for manufacturing components such as valves, fittings, and heat exchangers in corrosive environments.

Aluminum alloys, such as AlSi10Mg, are valued for their low density, high thermal conductivity, and good castability. They are extensively used in the automotive and electronics industries. In the automotive industry, PBF - made aluminum alloy parts can reduce the weight of vehicles, improving fuel efficiency. For instance, an aluminum alloy engine bracket produced by PBF can be 30% lighter than its conventionally - made counterpart, while still meeting the required mechanical strength for vehicle operation.

Ceramic Powders

Ceramic powders have unique properties that make them suitable for specific applications in PBF. Ceramics are known for their high hardness, excellent heat resistance, and chemical stability.

One common application of PBF - processed ceramics is in the aerospace industry for manufacturing high - temperature components. For example, silicon carbide (SiC) ceramics can withstand temperatures up to 1600°C. Turbine blades made from SiC ceramics using PBF can operate in extremely high - temperature environments in aircraft engines, improving the efficiency and performance of the engines. These ceramic turbine blades can also reduce the weight of the engine components, contributing to overall aircraft weight reduction.

In the medical field, bioceramics such as hydroxyapatite are used to produce bone - like structures for tissue engineering. Hydroxyapatite has a chemical composition similar to that of natural bone, making it highly biocompatible. When fabricated into scaffolds using PBF, these structures can provide a framework for cell growth and tissue regeneration. A study showed that in a tissue engineering experiment, cells seeded on PBF - made hydroxyapatite scaffolds grew and differentiated successfully, indicating the potential of these scaffolds for treating bone defects.

Polymer Powders

Polymer powders are widely used in PBF for a variety of applications, especially in the consumer product and prototyping sectors.

Materials like nylon (PA) are popular due to their good mechanical properties, including high strength and toughness. Nylon parts made by PBF have a tensile strength of approximately 40 - 60 MPa. In the consumer product industry, nylon is used to create items such as customized shoe insoles. These insoles can be designed to fit an individual's foot shape precisely, providing better comfort and support. According to market research, the use of nylon in 3D - printed consumer products has been increasing at an annual rate of about 15% in recent years.

Another commonly used polymer is polypropylene (PP). PP has good chemical resistance, low density, and is relatively inexpensive. It is often used for manufacturing consumer goods such as toys, containers, and small household items. For example, small, customized storage containers made from PP using PBF can be produced quickly and cost - effectively, meeting the diverse needs of consumers. In the consumer product market, the share of PBF - made PP products has been steadily growing, accounting for about 20% of all PBF - produced polymer - based consumer products in 2023.

Yigu Technology's View

As a non - standard plastic metal products custom supplier, Yigu Technology highly values powder bed fusion additive manufacturing. We have been actively involved in related research and development, aiming to explore more innovative applications of this technology in non - standard product manufacturing.

In terms of metal products, we have successfully used powder bed fusion technology to produce complex - shaped metal components with high precision for some high - end equipment manufacturers. These components not only meet the strict requirements of customers in terms of performance but also show significant advantages in cost - effectiveness compared to traditional manufacturing methods. For example, in the production of certain custom - made metal brackets, the use of powder bed fusion additive manufacturing has reduced the production cycle by 30% and material waste by 25%.

In the future, we plan to further expand the application of powder bed fusion additive manufacturing in the field of non - standard plastic products. By optimizing the process parameters and material selection, we strive to produce more high - quality, customized plastic and metal products to meet the diverse needs of our customers in various industries.