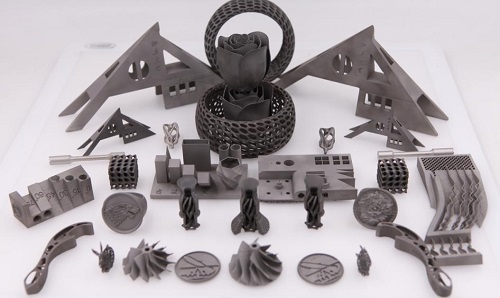

SLS (Selective Laser Sintering) 3D printing is an advanced manufacturing technology that uses high-powered lasers to fuse powdered materials, layer by layer, to create complex, durable 3D objects. This process allows for the production of intricate designs with high precision, making it especially popular in industries like automotive, aerospace, medical, and consumer goods. SLS 3D printing offers unparalleled design flexibility, faster production times, and the ability to produce both functional prototypes and end-use parts. This guide explores how SLS works, its advantages, key applications, and how to choose the right provider for your needs.

Introduction to SLS 3D Printing

Definition and Principles

SLS 3D printing is an additive manufacturing technique where a laser selectively sinters (fuses) layers of powdered material to build an object. Unlike other methods that use liquid resins or filament, SLS relies on a powder bed consisting of fine material particles. The laser follows a predefined path, based on a 3D model, to sinter specific areas of the powder. This layer-by-layer process continues until the object is fully formed.

The core principle behind SLS lies in the precise control of the laser’s power and movement. As each layer is completed, the build platform lowers slightly, and a new layer of powder is spread over the previous one. The laser then fuses this new layer, bonding it to the one below, and the process repeats until the object is finished.

Advantages Over Other 3D Printing Methods

SLS 3D printing offers several unique advantages compared to other methods like FDM (Fused Deposition Modeling) and SLA (Stereolithography):

- Design Flexibility: SLS allows for the creation of intricate geometries, including internal channels, undercuts, and lightweight structures that are challenging to achieve with traditional manufacturing techniques.

- Material Variety: A wide range of materials is compatible with SLS, including plastics, metals, composites, and ceramics, enabling the production of parts with different mechanical properties.

- Durability: Parts made with SLS are strong, durable, and suitable for functional use, not just prototyping.

- Smooth Surface Finish: SLS typically produces smoother surfaces than FDM, often requiring little to no post-processing.

- Speed: Although not as fast as some other methods, SLS provides relatively fast production times, especially for complex parts.

How SLS 3D Printing Works

The Sintering Process

The SLS process involves several key steps:

- Preparation: A 3D model is designed using CAD software and converted into a format compatible with the printer (typically STL or SLC). The model is sliced into layers that the printer will build.

- Powder Layering: A thin layer of powder is spread evenly across the build platform. This forms the foundation for the first layer of the object.

- Laser Sintering: The laser beam scans the powder, fusing the material particles according to the pattern in the 3D model. This forms the first layer of the object.

- Layer-by-Layer Construction: After each layer is sintered, the build platform lowers slightly, and another layer of powder is spread. The laser then sinters this new layer, bonding it to the one below. This continues until the entire object is built.

- Cooling and Extraction: Once the object is complete, the build chamber is cooled, and the excess powder is removed, leaving the final printed part. The unused powder can often be reused for future prints.

Material Selection and Layering

SLS supports a variety of materials, each offering specific benefits:

- Polyamide (Nylon): A popular choice due to its strength, flexibility, and durability. It’s commonly used for functional parts and prototypes.

- Polystyrene: Known for its fine detail and is typically used for intricate, low-stress parts.

- Metals: Metal powders (like titanium, stainless steel, and aluminum) can be used for high-strength, heat-resistant parts required in industries like aerospace and automotive.

- Composites: Materials like glass-filled nylon provide enhanced mechanical properties for demanding applications.

The layering process ensures high precision, with each layer typically ranging from 0.05 mm to 0.2 mm thick. Proper powder spreading, laser control, and cooling are essential to achieving quality results.

Applications of SLS 3D Printing

Industrial Applications

SLS has become a key technology across many industries due to its ability to create functional, high-performance parts:

- Automotive: SLS is used for rapid prototyping, producing custom parts, and creating tooling for low-volume manufacturing.

- Aerospace: The lightweight, strong parts produced by SLS are ideal for the aerospace sector, where weight reduction is crucial and parts must meet high-performance standards.

- Medical: SLS enables the production of customized implants, prosthetics, and surgical guides, allowing for better patient-specific solutions.

- Consumer Goods: SLS is also used for producing complex parts for consumer electronics, wearable devices, and other products that require precision and customization.

Prototyping and Product Development

SLS 3D printing is widely used in prototyping and product development due to its speed and precision:

- Rapid Prototyping: Quickly produces functional prototypes for design validation and testing, enabling rapid iteration.

- Bridge Tooling: SLS is used to create molds and tooling for injection molding or die-casting, reducing lead times and costs.

- Concept Models: Produces detailed concept models that help visualize designs and communicate ideas to stakeholders or clients.

Benefits of SLS 3D Printing Service

Design Flexibility

SLS 3D printing offers significant design advantages:

- Complex Geometries: It allows the creation of intricate designs with internal features, overhangs, and intricate shapes not possible with traditional methods.

- Customization: SLS supports mass customization, making it ideal for industries like medical devices, where products are often tailored to individual requirements.

- Rapid Iteration: The speed of the SLS process makes it possible to quickly test and refine designs, reducing time-to-market.

Cost-Efficiency

While SLS 3D printing may have a higher initial setup cost compared to other methods, it offers substantial long-term cost benefits:

- Reduced Waste: As an additive process, SLS only uses the material needed for the part, minimizing waste. Any unused powder can typically be reused.

- No Tooling Costs: Traditional manufacturing often requires expensive molds and tooling; SLS eliminates this need, especially for low-volume production runs.

- Faster Time-to-Market: Rapid prototyping and the ability to quickly adjust designs result in faster development cycles and product launches.

- On-Demand Production: SLS supports just-in-time manufacturing, which reduces inventory and storage costs.

Choosing an SLS 3D Printing Service Provider

Key Selection Criteria

When selecting an SLS 3D printing service provider, consider the following factors:

- Experience: Choose a provider with a strong track record in SLS 3D printing and a deep understanding of the technology.

- Material Options: Ensure the provider offers the materials you need for your application (plastics, metals, composites, etc.).

- Quality Control: Verify that the provider follows stringent quality control procedures to ensure consistent results.

- Turnaround Time: Check the provider’s production capacity and their ability to meet your deadlines.

- Pricing Transparency: Get clear quotes on pricing, including setup fees, material costs, and any additional charges.

- Customer Support: Ensure the provider offers excellent support throughout the design, production, and post-production stages.

Service Offerings

Look for providers that offer a range of services, such as:

- Full-Service Printing: Including design consultations, file preparation, and post-processing like sanding or painting.

- Prototype Development: Help with design optimization and rapid prototyping.

- Volume Production: The ability to handle both small and large production runs.

- Customization: Tailored solutions for unique project needs, such as specific material requirements or finishes.

- Technical Support: Advice on material selection, design considerations, and process optimization.

Conclusion

SLS 3D printing is a powerful, versatile manufacturing technique that offers significant advantages over traditional production methods. Its ability to produce complex, high-precision parts from a variety of materials makes it ideal for industries like automotive, aerospace, medical, and consumer goods. By understanding how SLS works and selecting the right service provider, businesses can leverage this technology to accelerate product development, reduce costs, and achieve innovative solutions. Whether you're producing functional prototypes, custom components, or low-volume production parts, SLS 3D printing offers a cost-effective and flexible solution.