Introduction

In the fast - paced world of modern manufacturing, rapid prototyping has emerged as a crucial process. It allows companies to quickly transform their design concepts into tangible models, significantly reducing the time and cost associated with product development. Among the various materials used in rapid prototyping, aluminum stands out for its unique properties and wide - ranging applications. This article aims to answer all your questions regarding "rapid prototyping aluminum", from the basic concepts to advanced techniques, helping you make informed decisions for your manufacturing needs.

What is Rapid Prototyping Aluminum?

Definition

Rapid prototyping aluminum refers to the process of quickly manufacturing aluminum - based prototypes through specific technologies. It plays a vital role in the early stages of product development. In product design, ideas are often abstract, and turning these ideas into a tangible physical form is the first step towards product realization. Aluminum prototypes allow designers and engineers to visually and physically evaluate the design, check for design flaws, and make improvements before mass production. For example, in the automotive industry, when developing a new engine component, creating a rapid prototyping aluminum model helps in validating the fit, function, and performance of the part in a short time, reducing the time - consuming and costly iterative processes later.

Key Technologies Involved

- 3D Printing: Also known as additive manufacturing, 3D printing builds the aluminum prototype layer by layer based on a digital model. The selective laser melting (SLM) technique, a type of metal 3D printing, uses a high - power laser to melt and fuse aluminum powder together. It has the advantage of high design freedom, being able to create complex geometries that are difficult to achieve with traditional manufacturing methods. For instance, internal cooling channels with intricate shapes can be designed and printed directly, which is beneficial for heat dissipation in aerospace components. However, 3D - printed aluminum parts may have porosity issues, and the surface finish may not be as smooth as that of parts made by some other methods.

- CNC Machining: Computer - Numerical - Control (CNC) machining is a subtractive manufacturing process. In CNC milling for aluminum, a rotating cutting tool removes material from a solid aluminum block according to pre - programmed instructions. CNC turning is mainly used for creating cylindrical parts. This technology offers high precision, with tolerances that can reach as low as ±0.001 inches in some cases. It is suitable for producing aluminum prototypes with tight tolerances and smooth surface finishes, such as those required for high - end consumer electronics or medical device components. But it can be time - consuming for complex shapes as it needs to gradually remove the excess material.

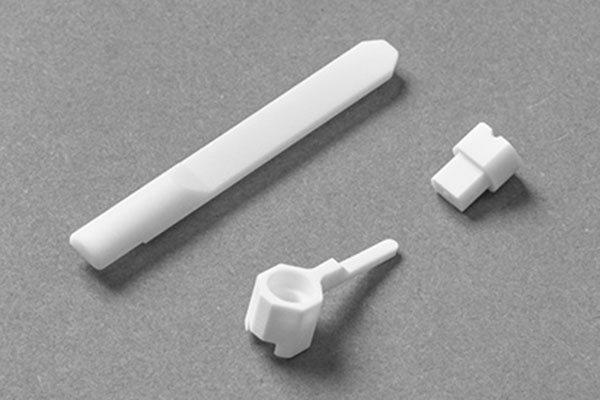

- Die Casting: Although not as "rapid" as 3D printing or CNC machining in some aspects, die casting is still an important method for rapid prototyping aluminum in certain scenarios. In die casting, molten aluminum is forced into a mold cavity under high pressure. It is efficient for producing medium - to high - volume prototypes with relatively simple geometries. For example, many household appliance parts like aluminum alloy housings can be quickly prototyped through die casting. The process can produce parts with good dimensional stability and surface quality, but it requires the production of molds first, which can be costly and time - consuming for one - off prototypes.

Applications of Rapid Prototyping Aluminum

Aerospace Industry

In the aerospace industry, the demand for lightweight yet high - strength materials is crucial. Aluminum prototypes made through rapid prototyping play a significant role. For example, engine components such as turbine blades and compressor parts are often prototyped using aluminum. These components need to withstand high temperatures and mechanical stresses during operation. By using rapid prototyping aluminum, engineers can optimize the design of these parts, reducing their weight by up to 30% compared to traditional materials, while maintaining or even improving their mechanical properties. This weight reduction directly contributes to fuel efficiency, as less energy is required to propel the aircraft. In addition, aluminum rapid - prototyped fuselage structural parts can enhance the overall strength - to - weight ratio of the aircraft, improving its maneuverability and range.

Automotive Industry

The automotive industry also benefits greatly from rapid prototyping aluminum. Engine blocks are a prime example. Aluminum engine blocks made through rapid prototyping techniques are lighter than their cast - iron counterparts, with a weight reduction of approximately 20 - 40%. This reduction in weight not only improves the power - to - weight ratio of the vehicle but also leads to better fuel efficiency, with some studies showing a potential increase of 5 - 10% in fuel economy. Wheels are another area where aluminum rapid prototyping is applied. Aluminum alloy wheels made through rapid prototyping can be designed with complex and lightweight structures, which not only enhance the aesthetics of the vehicle but also reduce unsprung mass, improving handling and braking performance.

Electronics Industry

In the electronics industry, rapid prototyping aluminum is widely used in the production of heat sinks and enclosures. Heat sinks are essential for dissipating the heat generated by electronic components, ensuring their stable operation. Aluminum heat sinks made through rapid prototyping can be designed with intricate fin structures, increasing the surface area for heat dissipation. Tests show that these aluminum heat sinks can effectively lower the operating temperature of electronic components by 10 - 15°C compared to some traditional heat - sink materials. For enclosures, aluminum provides excellent protection against electromagnetic interference (EMI) and physical damage. The high - precision manufacturing capabilities of rapid prototyping aluminum ensure a perfect fit for the internal components, protecting them from external impacts and environmental factors.

Yigu Technology's Viewpoint

As a non - standard plastic and metal products custom supplier, Yigu Technology highly values the role of rapid prototyping aluminum in modern manufacturing. We have a professional team with in - depth knowledge of various rapid prototyping technologies for aluminum.

Our advantage lies in our ability to provide customized solutions according to different customer needs. Whether it's complex 3D - printed aluminum prototypes for innovative product designs or high - precision CNC - machined aluminum parts, we can ensure high - quality production. We also offer a one - stop service, from the initial design consultation to the final product delivery, which includes surface treatment to enhance the appearance and performance of the aluminum prototypes.

By choosing Yigu Technology, customers can effectively utilize rapid prototyping aluminum technology. We help them optimize product design, reduce development cycles, and cut down costs, thus achieving better competitiveness in the market.

FAQ

What are the common materials used in rapid prototyping aluminum?

Common materials for rapid prototyping aluminum include 6061 aluminum alloy. It has good mechanical properties, high strength - to - weight ratio, and excellent corrosion resistance. It is easy to machine and weld, making it suitable for a wide range of applications such as aerospace and automotive parts. Another popular material is 7075 aluminum alloy. Known for its high strength, especially in the T6 temper condition, it is often used in applications where high - stress resistance is required, like aircraft structural components. However, it is more difficult to machine compared to 6061 due to its higher hardness.

How accurate is the rapid prototyping aluminum process?

The accuracy of rapid prototyping aluminum processes varies. In 3D printing (SLM), the dimensional accuracy can typically reach ±0.1 - ±0.3 mm for small - to medium - sized parts. Factors affecting accuracy include the quality of the powder material, laser power stability, and the post - processing methods. CNC machining offers high precision, with tolerances often in the range of ±0.01 - ±0.05 mm for general applications, and in some high - end machining centers, it can achieve tolerances as low as ±0.001 inches. The accuracy in CNC machining depends on factors such as the machine's precision, tool wear, and the quality of the CAM programming. Die casting can achieve an accuracy of ±0.1 - ±0.5 mm for medium - sized parts, and the accuracy is mainly affected by the mold design, the temperature control during the casting process, and the material shrinkage rate.

Can rapid prototyping aluminum be used for large - scale production?

Rapid prototyping aluminum has some limitations for large - scale production. 3D printing, although highly flexible in design, has relatively low production speeds. For example, a small aluminum part may take several hours to print, which is not efficient for high - volume production. Also, the cost per unit for 3D - printed aluminum parts is high due to the expensive equipment and materials. CNC machining is time - consuming for large - scale production as it is a subtractive process. Each part requires individual machining operations, and for large volumes, the cumulative machining time can be substantial. Die casting, on the other hand, is more suitable for medium - to high - volume production of parts with relatively simple geometries. Once the mold is made, it can produce parts relatively quickly. However, the high initial cost of mold making can be a deterrent for small - scale production runs. So, in general, while rapid prototyping aluminum can be used for small - scale production or pre - production trials, for large - scale production, traditional mass - production methods may be more cost - effective and efficient, depending on the part complexity and production volume requirements.