Understanding Prototype Metal Parts

In the realm of product development, prototype metal parts play a pivotal role. But what exactly are they? A prototype metal part is an early - stage model of a final metal product. It serves as a tangible representation of the design concept, allowing engineers, designers, and clients to evaluate the form, fit, and function before mass production.

The Importance in the Product Development Process

- Design Validation: Prototype metal parts are crucial for validating a product's design. For example, in the automotive industry, when developing a new engine component, creating a prototype metal part enables engineers to check if all the dimensions are correct, if the part can be assembled easily with other components, and if it can withstand the expected mechanical stresses. According to a study by the Product Development and Management Association, over 70% of successful product launches had comprehensive prototype testing, with metal prototypes being a significant part in mechanical product development.

- Function Testing: They allow for rigorous function testing. Suppose a company is developing a new metal - based medical device. The prototype metal part can be used to test its functionality, such as how well it interacts with biological tissues, its durability during repeated use, and its sterilization capabilities. This helps in identifying design flaws early on, reducing the cost of making changes in the later production stages.

- Cost - Effective in the Long Run: Although the creation of prototype metal parts incurs some initial costs, it saves a substantial amount in the long run. By detecting and rectifying issues in the prototype stage, companies can avoid costly production line stoppages, retooling, and product recalls. A report by McKinsey & Company shows that companies that invest in proper prototyping can reduce production costs by up to 30% in the long - term product lifecycle.

Different Manufacturing Methods for Prototype Metal Parts

When it comes to creating prototype metal parts, several manufacturing methods are at your disposal, each with its own set of advantages and ideal applications.

CNC Machining

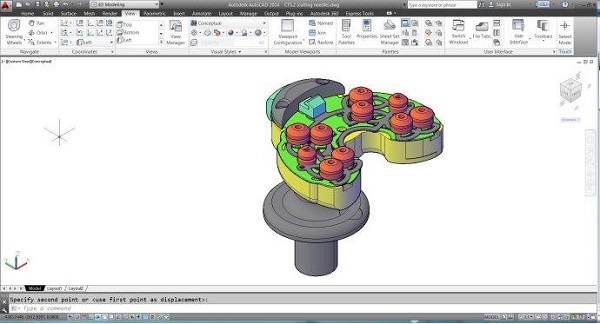

CNC (Computer Numerical Control) machining is a widely used method in the production of prototype metal parts. The principle behind CNC machining is straightforward: a pre - programmed computer software controls the movement of machine tools, such as mills, lathes, or routers. This automation allows for highly precise operations.

Advantages

- High Precision: CNC machining offers exceptional precision, often achieving tolerances within ±0.01mm or even better in some advanced setups. In contrast, traditional manual machining may have a tolerance range of ±0.1mm - ±0.5mm. For example, in the aerospace industry, where the slightest deviation can lead to catastrophic consequences, CNC - machined turbine blades for jet engines need to be extremely precise. The high - precision capabilities of CNC machining ensure that these critical components meet the strictest quality standards.

- Complex Shape Machining: It can handle the creation of intricate shapes with ease. Through multi - axis machining (such as 3 - axis, 4 - axis, or 5 - axis), CNC machines can carve out complex geometries that would be nearly impossible to achieve through other means. In the automotive industry, CNC - machined engine blocks with complex internal cooling channels are a common example. These channels are designed to optimize the engine's performance by efficiently dissipating heat, and CNC machining makes their production feasible.

3D Printing

3D printing, also known as additive manufacturing, is revolutionizing the way prototype metal parts are made. The basic principle of 3D printing involves building up a three - dimensional object layer by layer from a digital model.

Ideal for Small - Batch and Complex - Structure Prototypes

- Small - Batch Production: 3D printing is cost - effective for small - batch production of prototype metal parts. Since there is no need for expensive molds as in traditional manufacturing methods, setting up the production process for a small number of parts is much simpler and less costly. For startups or small - scale product development projects, this can significantly reduce the upfront investment.

- Complex Structures: It shines when it comes to creating parts with complex internal structures or geometries. For instance, in the medical field, 3D - printed metal implants can be designed with porous structures that mimic natural bone, promoting better integration with the patient's body. In the creative design industry, artists and designers can use 3D printing to bring their highly intricate and unique metal artworks to life. A jewelry designer might use 3D printing to create a prototype of a necklace with a complex, interwoven metal pattern that would be extremely difficult to manufacture using traditional casting methods.

Investment Casting

Investment casting, also called lost - wax casting, is a time - honored method with a long - standing reputation for producing high - quality prototype metal parts. The process begins with creating a wax pattern of the desired part. This wax pattern is then coated with a layer of refractory material, such as ceramic, to form a mold. Once the mold is set, the wax is melted and removed (hence the term "lost - wax"), leaving behind a hollow cavity in the shape of the part. Molten metal is then poured into this cavity. After the metal cools and solidifies, the mold is broken away, revealing the finished metal part.

Advantages in High - Precision and Complex - Shape Production

- High Precision: Investment casting can achieve high levels of precision, with dimensional tolerances typically in the range of ±0.05mm - ±0.2mm. This makes it suitable for applications where accuracy is crucial.

- Complex Shapes: It is well - suited for producing parts with complex shapes and fine details. In the jewelry industry, investment casting is commonly used to create intricate and detailed jewelry pieces. For example, a delicate filigree - style ring or a detailed pendant with fine engravings can be accurately reproduced through investment casting. In the production of art prototypes, artists can use this method to create highly detailed metal sculptures, ensuring that every curve and contour of their original design is faithfully captured in the metal prototype.

Material Selection for Prototype Metal Parts

The choice of material for prototype metal parts is a crucial decision that can significantly impact the performance, cost, and manufacturability of the final product. Here are some common materials and their characteristics:

Aluminum Alloys

Aluminum alloys are widely used in prototype metal part production. They have a relatively low density, approximately 2.7 g/cm³, which makes them lightweight. This property is highly desirable in applications where weight reduction is a priority, such as in the aerospace and automotive industries. For example, many aircraft components like wing structures and engine casings use aluminum alloy prototypes to ensure both light - weight and sufficient strength during the design validation phase.

Aluminum alloys also offer good corrosion resistance, especially when properly treated. They can withstand exposure to various environmental conditions, including moisture and some chemicals. In terms of strength, while pure aluminum is relatively soft, alloying it with elements like copper, magnesium, or zinc can significantly enhance its strength. However, their strength is generally lower compared to steel alloys, with an ultimate tensile strength typically ranging from 200 - 600 MPa for common aluminum alloys used in prototypes.

Steel Alloys

Steel alloys are known for their high strength and durability. The density of steel is around 7.8 g/cm³, which is much higher than aluminum, making steel - based prototype parts heavier. But this comes with the advantage of superior strength. For instance, in the construction of heavy - duty machinery prototypes, steel is often the material of choice. A prototype of a large - scale industrial crane's structural components would likely be made of steel to ensure it can handle the massive loads during testing.

There are different types of steel alloys, such as carbon steel, alloy steel, and stainless steel. Carbon steel is relatively inexpensive and offers good strength, but it is prone to rusting. Alloy steel, with the addition of elements like chromium, nickel, or molybdenum, has enhanced mechanical properties and can be heat - treated to achieve specific strength - toughness combinations. Stainless steel, on the other hand, is highly corrosion - resistant due to its high chromium content, making it suitable for applications where resistance to chemical corrosion is essential, like in the food and medical industries. The tensile strength of steel alloys can range widely, from around 400 MPa for low - carbon steel to over 1500 MPa for high - strength alloy steels.

Titanium Alloys

Titanium alloys are characterized by their excellent strength - to - weight ratio. With a density of about 4.5 g/cm³, they are lighter than steel but stronger than many aluminum alloys. Their strength is particularly notable at high temperatures, and they also exhibit outstanding corrosion resistance, even in harsh environments such as seawater. This makes them ideal for aerospace applications, like jet engine components, and marine applications, such as ship propellers.

Titanium alloys are biocompatible as well, which is why they are increasingly used in the medical field for implants and prosthetics. However, titanium alloys are more expensive and more difficult to machine compared to aluminum and steel. The cost is due to the complex extraction process of titanium from its ores, and the machining difficulty is because titanium has a high chemical reactivity at high temperatures, which can cause problems during cutting and shaping operations. The tensile strength of common titanium alloys used in prototypes can range from 500 - 1000 MPa.

Here is a comparison table of the key properties of these materials:

| Material | Density (g/cm³) | Strength (MPa, approximate range) | Corrosion Resistance |

| Aluminum Alloys | 2.7 | 200 - 600 | Good |

| Steel Alloys | 7.8 | 400 - 1500+ | Varies (stainless steel is high, carbon steel is low without protection) |

| Titanium Alloys | 4.5 | 500 - 1000 | Excellent |

Yigu Technology's View

As a non - standard plastic metal products custom Supplier, Yigu Technology has rich experience in the production of prototype metal parts. We understand that each client's need for prototype metal parts is unique. Whether it's a startup with an innovative product concept or a large - scale enterprise looking to upgrade an existing product, we are committed to providing tailored solutions.

Our technical team, composed of experienced engineers, is proficient in various manufacturing methods, from traditional CNC machining to advanced 3D printing and investment casting. We use state - of - the - art equipment and software to ensure high - precision production. Moreover, we place great emphasis on communication with clients. Starting from the initial design stage, we work closely with clients to understand their requirements, providing professional advice on material selection and manufacturing processes. This collaborative approach helps us create prototype metal parts that not only meet but exceed client expectations, while also ensuring cost - effectiveness and timely delivery.

FAQ

What is the most suitable manufacturing method for complex - shaped prototype metal parts?

For complex - shaped prototype metal parts, 3D printing and investment casting are highly suitable. 3D printing can build parts layer by layer according to digital models, allowing for the creation of extremely complex internal structures and geometries that are difficult to achieve with traditional methods. Investment casting, or lost - wax casting, can accurately replicate complex shapes and fine details. It creates a wax pattern first, coats it with a refractory material to form a mold, melts out the wax, and then pours in molten metal. This process is ideal for parts with intricate designs, such as detailed jewelry or art prototypes.

How to ensure the accuracy of prototype metal parts?

To ensure the accuracy of prototype metal parts, first, choose the right manufacturing method. For example, CNC machining can achieve high precision, often with tolerances within ±0.01mm in advanced setups. 3D printing also has good precision for its layer - by - layer building process. Second, strict quality control and measurement are essential. Use high - precision measuring tools like coordinate measuring machines (CMMs) to measure the dimensions of the prototype metal parts during and after production. Compare the measured values with the design specifications and make adjustments if there are any deviations. Regular calibration of the manufacturing equipment and measuring tools is also crucial to maintain accuracy over time.

Can I choose different materials for prototype metal parts according to my needs?

Yes, you can. Aluminum alloys are a great choice when you need lightweight parts with good corrosion resistance, such as in aerospace or automotive applications. Steel alloys are suitable for applications that require high strength and durability, like heavy - duty machinery. Titanium alloys offer an excellent strength - to - weight ratio and outstanding corrosion resistance, making them ideal for aerospace, marine, and medical applications. Consider factors like the part's function, the operating environment, and cost when choosing materials. For example, if the part will be exposed to a corrosive environment, stainless steel or titanium alloys might be more appropriate. If cost is a major concern and strength requirements are not extremely high, aluminum alloys could be a cost - effective option.