Imagine a medical device company trying to machine a 0.1 mm diameter hole in a stainless steel sensor, only to find that their standard CNC equipment can’t achieve the required precision—resulting in parts that fail calibration. Or an electronics manufacturer struggling to produce micro gears with 50 μm teeth, as tool deflection causes inconsistent sizing. These are the challenges of micro machining CNC—a specialized field where precision is measured in microns (1 μm = 0.001 mm) and even the smallest error can render a part useless. In this guide, we’ll explore how micro machining CNC works, the equipment and processes involved, and how to overcome its unique challenges to produce high-quality micro components.

Micro Machining CNC Basics: The Fundamentals of Miniaturization

Micro machining is the process of creating tiny features (often smaller than 1 mm) with extreme precision, and CNC (Computer Numerical Control) is the technology that makes this possible. Unlike conventional machining, which handles larger parts with tolerances of ±0.01 mm or more, micro machining CNC targets tolerances as tight as ±0.1 μm—equivalent to 1/500th the width of a human hair.

- Precision Engineering is at the core, requiring machines and tools that can move with sub-micron accuracy. Even environmental factors like temperature (variations of ±1°C can cause material expansion) and vibration (from nearby equipment) must be controlled.

- Miniaturization isn’t just about size—it’s about replicating complex geometries at a small scale. A micro fluidic chip for medical diagnostics, for example, might include 50 μm wide channels with 90° corners, requiring tool paths programmed to 0.1 μm resolution.

- Tool Path Programming for micro machining uses specialized CAM software that accounts for tiny tool sizes (0.1–1 mm diameter) and low cutting forces. A single mistake in the program can lead to tool breakage or surface damage.

- Micro Features like micro holes, slots, and threads demand unique approaches. A 0.5 mm diameter thread, for instance, requires a tap with 0.1 mm pitch—so small that it can’t be seen clearly with the naked eye.

A study by the Micro Manufacturing Technology Association found that 65% of micro machining errors stem from inadequate understanding of these basics, highlighting the need for specialized knowledge.

Micro Machining CNC Equipment: Tools for Tiny Tasks

The right equipment is critical for micro machining CNC success. These machines and tools are engineered to handle the demands of micron-level precision:

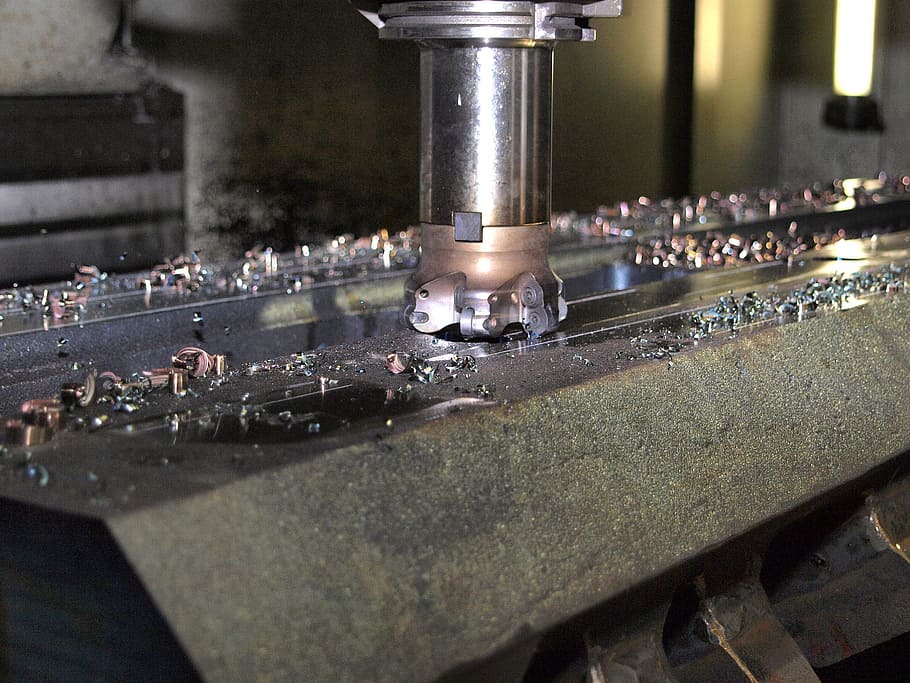

- CNC Machines for micro machining include micro milling machines and micro lathes with high-resolution encoders (0.01 μm) and rigid frames to minimize vibration. A typical micro mill might have a worktable travel of 100 mm × 100 mm, but with positioning accuracy of ±0.5 μm.

- High-Speed Spindles (30,000–150,000 RPM) are essential. At these speeds, a 0.5 mm carbide end mill can cut material efficiently without generating excess heat. A spindle running at 100,000 RPM completes 1,666 rotations per second—fast enough to create smooth finishes on micro features.

- Micro Cutting Tools are often made from ultra-hard materials like carbide or diamond. A 0.1 mm diameter diamond-coated end mill can machine 1,000+ micro slots in stainless steel before needing replacement, compared to 100+ for standard carbide.

- Micro EDM (Electrical Discharge Machining) is used for features too small for mechanical cutting. Wire EDM with 0.02 mm diameter wire can create 0.03 mm wide slots in hardened steel, ideal for micro sensors.

- Laser Cutting Machines with femtosecond lasers (pulse durations of 10–15 seconds) ablate material without heat damage, making them perfect for micro holes in delicate materials like glass or polymers.

Micro Machining CNC Processes: Techniques for Micron-Level Results

Micro machining CNC processes are tailored to the unique demands of small-scale manufacturing:

- Micro Milling creates 3D features using tiny end mills. Climb milling (feeding the tool against its rotation) reduces tool deflection, critical for 0.1 mm diameter tools. A 5-axis micro mill can produce a micro impeller with 0.5 mm blades, achieving surface finishes as smooth as Ra 0.05 μm.

- Micro Drilling uses drills as small as 0.05 mm to create holes. Peck drilling (retracting the drill 0.1 mm after each 0.2 mm cut) removes chips and prevents jamming—essential for deep holes (5× diameter or more).

- Micro Turning shapes cylindrical parts like micro shafts (0.5–5 mm diameter) on a micro lathe. A diamond-tipped tool can achieve roundness within 0.5 μm, ensuring proper fit in bearings.

- Laser Micromachining uses focused laser beams to cut or ablate material. It’s ideal for micro holes in ceramics or polymers, with positional accuracy of ±1 μm. A sensor manufacturer uses laser micromachining to create 0.02 mm holes in a 0.1 mm thick titanium foil.

- Process Optimization involves balancing speed and precision. For example, a micro gear with 50 μm teeth might require a feed rate of 5 mm/min and spindle speed of 60,000 RPM—slow enough to prevent tool wear, but fast enough to maintain productivity.

Applications of Micro Machining CNC: Where Small Parts Make a Big Impact

Micro machining CNC enables innovations across industries by producing components that conventional manufacturing can’t:

- Medical Devices: Micro machined parts include 0.1 mm diameter needles, 50 μm thick surgical blades, and implantable sensors with microelectrodes. A pacemaker’s lead wire has micro features that improve tissue compatibility.

- Micro Electronics: Connectors, microchips, and sensor components rely on micro machining. A 5G antenna uses micro milled slots (0.1 mm wide) to optimize signal transmission.

- Aerospace Components: Micro valves and fuel injectors in small drones use micro machined parts to reduce weight. A micro valve with 0.5 mm ports controls fuel flow with ±1% accuracy.

- Micro Fluidics: Devices like lab-on-a-chip systems use micro channels (20–100 μm wide) to manipulate tiny fluid volumes. These are used for rapid medical diagnostics and chemical analysis.

- Micro Optics: Lenses, prisms, and optical connectors with micro features (0.1 μm surface finish) improve light transmission. A smartphone camera’s micro lens holder is micro machined to ensure precise alignment.

Challenges in Micro Machining CNC: Overcoming the Hurdles

Micro machining CNC comes with unique challenges, but they’re manageable with specialized approaches:

- Tool Wear: Tiny tools (0.1 mm diameter) wear quickly—often after 10–20 minutes of cutting. Using diamond coatings and reducing cutting forces (to 0.5 N or less) extends tool life by 300%.

- Surface Finish: Micro parts often require Ra values under 0.1 μm to function properly. A sharp tool with a high rake angle (20°) and slow feed rate (1–5 mm/min) achieves these finishes.

- Dimensional Accuracy: Thermal expansion of the workpiece or machine can cause errors of 1–5 μm. Controlling the environment to ±0.5°C and using temperature-compensated software reduces these errors by 80%.

- Tool Deflection: A 0.1 mm carbide tool can deflect 5 μm under 1 N of force, altering feature size. Reducing depth of cut to 0.01 mm and using rigid tool holders minimizes deflection.

- Environmental Control: Dust particles (5 μm or larger) can scratch micro surfaces. Manufacturing in a Class 100 cleanroom (fewer than 100 particles per cubic foot) prevents contamination.

Quality Control in Micro Machining CNC: Ensuring Micron-Level Precision

Quality control in micro machining CNC requires tools and techniques capable of measuring tiny features:

- Inspection Techniques include microscopy (optical and electron), which can visualize features as small as 0.1 μm. A scanning electron microscope (SEM) verifies the shape of 50 μm gear teeth.

- Dimensional Metrology uses tools like coordinate measuring machines (CMMs) with micro probes (0.1 mm diameter) to measure features with ±0.1 μm accuracy. A micro CMM can check 100+ dimensions on a 5 mm × 5 mm part in under 10 minutes.

- Surface Roughness Measurement uses profilometers with 0.01 μm resolution. For medical parts, Ra values must be under 0.05 μm to prevent bacterial adhesion.

- Non-Destructive Testing (NDT) like ultrasonic testing detects internal flaws in micro parts. A micro sensor manufacturer uses NDT to check for voids in 0.5 mm thick ceramic components.

- Regulatory Compliance is critical for medical and aerospace parts. Documentation includes material certificates, inspection reports, and process validation data to meet standards like ISO 13485 and AS9100.

Yigu Technology’s Perspective: Expertise in Micro Machining CNC

At Yigu Technology, we specialize in micro machining CNC for critical applications. Our equipment includes high-speed micro mills, micro EDM systems, and cleanroom facilities to handle tolerances as tight as ±0.1 μm. We use diamond tools and environmental controls (temperature, humidity, vibration) to ensure precision, and our quality control team uses SEM and micro CMMs for 100% inspection. Whether you need micro gears for electronics or tiny medical components, our expertise in micro machining delivers reliable, high-quality parts that meet your most demanding requirements.

FAQs

- What’s the smallest feature that can be machined with micro machining CNC?

Micro machining CNC can produce features as small as 5 μm (0.005 mm), such as micro slots or holes. Laser micromachining can even create 1 μm features in delicate materials like polymers.

- How long does it take to machine a micro part?

Cycle times vary by complexity: a simple 0.5 mm diameter hole takes 1–2 minutes, while a complex micro fluidic chip with 100+ channels can take 30–60 minutes. Small batches (1–100 parts) are typical for micro machining.

- What materials can be micro machined?

Most metals (stainless steel, titanium, aluminum), plastics (PEEK, PTFE), ceramics, and even glass can be micro machined. The process varies by material—e.g., EDM for hard metals, laser machining for ceramics.