Imagine a heavy machinery manufacturer struggling to machine a 5-meter-long steel frame, only to find that their equipment can’t maintain straightness within 0.5 mm—rendering the part useless for structural applications. Or a power generation company facing delays because their 3-ton turbine casing warped during machining, requiring costly rework. These are the challenges of large part machining—a specialized field where size, weight, and precision collide. Unlike micro machining, where the focus is on tiny features, large part machining demands equipment and expertise to handle components weighing tons and measuring meters, all while achieving tight tolerances. In this guide, we’ll explore how large part machining works, the tools involved, and how to overcome its unique challenges.

Large Part Machining Basics: Understanding the Scale

Large part machining refers to the manufacturing of components that exceed standard size limits—typically parts longer than 3 meters, heavier than 500 kg, or with complex geometries that can’t be handled by conventional equipment. The basics differ significantly from small-part machining:

- Definition and Scope: Large parts include everything from 10-meter ship propeller shafts to 2-ton industrial press frames. These components often serve as structural or functional cores in machinery, where failure can have catastrophic consequences.

- Precision Requirements: While tolerances (often ±0.1 mm for length) are larger than micro machining, achieving them is harder due to the part’s size. A 10-meter beam with a tolerance of ±0.5 mm requires the machine to maintain accuracy over a distance equivalent to three cars parked end-to-end.

- Material Types: Large parts are often made from high-strength materials like alloy steel, cast iron, or titanium. A 5-ton mining equipment frame, for example, might use 4140 steel (tensile strength 1,000 MPa) to withstand heavy loads.

- Custom Machining: Most large parts are one-of-a-kind or produced in small batches, requiring tailored processes. A shipyard, for instance, might need a custom 8-meter rudder stock with unique keyways and flanges.

A survey by the Heavy Machinery Manufacturers Association found that 70% of large part failures stem from machining inaccuracies, emphasizing the need for specialized knowledge.

Equipment for Large Part Machining: Tools for the Big Job

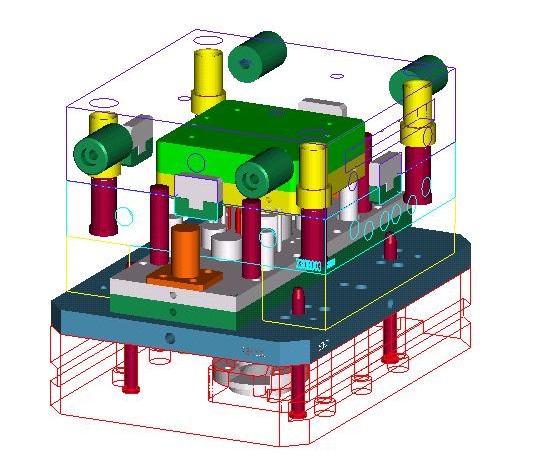

Large part machining requires equipment built for power, stability, and range:

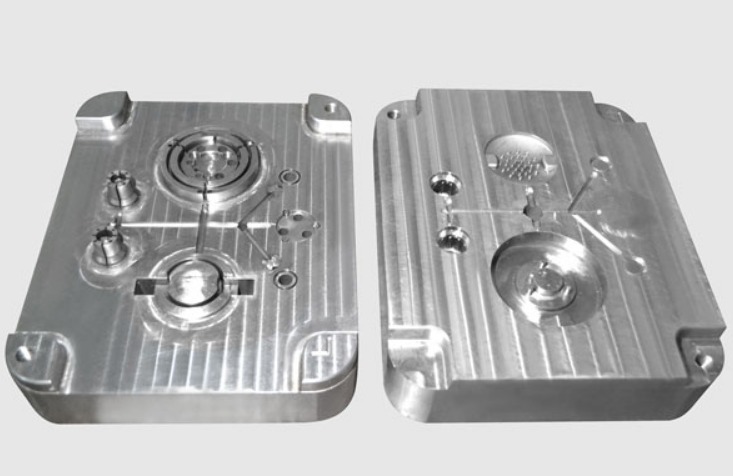

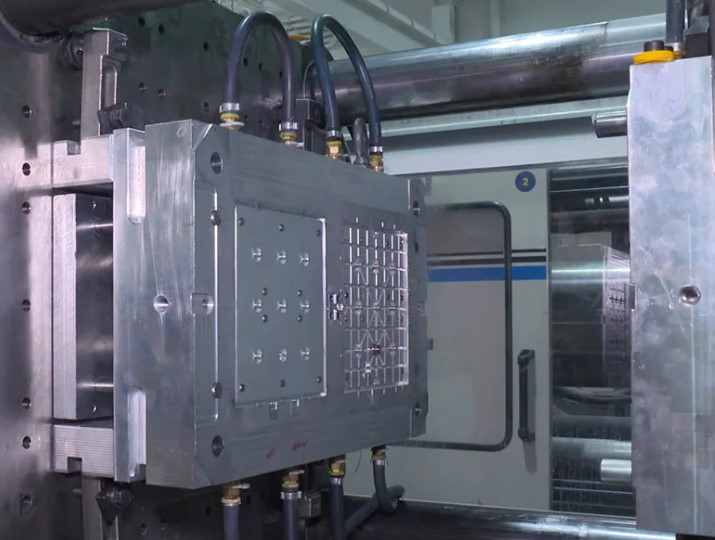

- Large Format CNC Machines are the workhorses, with beds measuring 5–30 meters. These machines feature reinforced frames (often cast iron or welded steel) to minimize vibration during heavy cuts.

- Gantry Mills use a moving bridge to cover large workpieces, ideal for machining flat surfaces like 10-meter industrial tables. A gantry mill with a 5-meter crossbeam can remove 50 kg of material per hour from a steel plate.

- Heavy-Duty Lathes handle cylindrical parts like shafts and pipes, with capacities up to 2 meters in diameter and 20 meters in length. A lathe for turbine rotors might have a 50-ton weight capacity and spindle torque of 10,000 Nm.

- Horizontal Boring Mills create precise holes in large structures, such as 100 mm diameter bores in a 3-ton gearbox housing. These machines can position the spindle with ±0.02 mm accuracy over 5 meters.

- Specialized Tooling includes 300 mm diameter face mills and 1-meter-long boring bars, often made from carbide or high-speed steel with coatings to resist wear. A 200 mm carbide insert can machine 1,000+ meters of steel before needing replacement.

Processes in Large Part Machining: Shaping Oversized Components

Large part machining processes combine brute force with precision:

- Milling removes material to create flat surfaces and contours. For a 5-meter-long crane arm, a CNC mill might use a 200 mm face mill at 500 RPM, feeding at 500 mm/min to achieve a Ra 3.2 μm surface finish.

- Turning shapes cylindrical parts, such as a 10-meter propeller shaft. A heavy-duty lathe might take 8 hours to turn the shaft from a 300 mm diameter blank to its final 250 mm diameter, maintaining straightness within 0.1 mm/m.

- Boring enlarges existing holes to precise diameters. A horizontal boring mill can bore a 200 mm diameter hole in a 2-ton engine block, achieving roundness within 0.01 mm.

- Heat Treatment is often part of the process, with large parts heated in furnaces capable of handling 10-ton loads. Stress relieving a 5-meter steel frame at 600°C for 24 hours reduces warpage during machining by 70%.

- Welding joins large sections, such as assembling a 15-meter bridge component from smaller steel plates. Post-weld machining ensures the assembled part meets dimensional specs.

Challenges in Large Part Machining: Overcoming the Hurdles

Large part machining comes with unique obstacles that require specialized solutions:

- Machine Stability: Vibrations from heavy cuts can reduce accuracy. Reinforced machine bases (with 100-ton concrete foundations) and anti-vibration pads reduce deflection by 80%.

- Heat Generation: Removing large amounts of material creates heat, which can warp parts. Coolant systems delivering 100+ liters per minute keep temperatures in check—critical for a 3-ton steel plate, where a 10°C temperature rise can cause 0.5 mm expansion.

- Handling and Transportation: Moving 10-ton parts requires cranes, forklifts, and custom fixtures. A aerospace manufacturer uses vacuum lifts with 20-ton capacity to position turbine casings without distortion.

- Tool Deflection: Long boring bars (1-meter+) can bend under cutting forces, altering hole diameter. Using rigid carbide bars and reducing feed rates (to 50 mm/min) minimizes deflection to under 0.02 mm.

- Dimensional Accuracy: Measuring large parts is challenging. A 10-meter beam might require laser trackers (accuracy ±0.05 mm over 50 meters) to verify straightness after machining.

Quality Control in Large Part Machining: Ensuring Big Parts Meet Big Standards

Quality control for large parts demands tools and techniques that can handle their size:

- Inspection Techniques include laser trackers and portable CMMs, which measure large features without moving the part. A laser tracker can check the flatness of a 5-meter table to within ±0.1 mm in 30 minutes.

- Dimensional Metrology for oversized components uses string potentiometers and optical comparators. For a 20-meter ship shaft, a laser alignment tool verifies concentricity between journals (±0.05 mm).

- Non-Destructive Testing (NDT) is critical for structural parts. Ultrasonic testing checks for internal flaws in a 3-ton pressure vessel, while magnetic particle inspection detects surface cracks in a 10-meter crane arm.

- In-Process Monitoring uses sensors to track cutting forces and temperatures. A CNC gantry mill with load cells can adjust feed rates if excessive force (over 10,000 N) indicates a dull tool, preventing workpiece damage.

- Regulatory Compliance is key for industries like aerospace and energy. Large parts must meet standards like AS9100 (aerospace) or API 6A (oil and gas), requiring detailed inspection reports and material traceability.

Applications of Large Part Machining: Where Size Matters

Large part machining enables critical infrastructure and machinery across industries:

- Aerospace: Machining 10-meter wing spars for commercial jets and 5-meter rocket fuel tanks, requiring tolerances of ±0.1 mm to ensure structural integrity.

- Marine: Producing 20-meter ship propeller shafts and 5-ton hull components, where corrosion resistance (achieved via precise surface finishes) is critical.

- Power Generation: Machining 3-ton turbine casings and 10-meter generator rotors for coal, gas, and wind power plants. These parts must withstand temperatures up to 600°C and pressures over 100 bar.

- Heavy Machinery: Manufacturing 5-meter excavator arms and 10-ton press frames for construction and mining equipment. A 3-ton hydraulic cylinder block requires 0.05 mm tolerance on bore diameters to prevent leaks.

- Industrial Structures: Creating 15-meter conveyor frames and 5-ton assembly line platforms, where flatness (within ±0.5 mm/m) ensures proper equipment alignment.

Yigu Technology’s Perspective: Expertise in Large Part Machining

At Yigu Technology, we specialize in large part machining for industries requiring precision at scale. Our facility houses large format CNC machines, gantry mills, and heavy-duty lathes capable of handling parts up to 15 meters long and 50 tons. We use laser trackers and portable CMMs for in-process inspection, ensuring tolerances as tight as ±0.1 mm. Whether machining a 10-meter aerospace component or a 3-ton industrial frame, our team combines technical expertise with robust processes to deliver reliable, high-quality large parts that meet your most demanding requirements.

FAQs

- What’s the largest part that can be machined?

Large part machining can handle components up to 30 meters long and 50 tons, such as ship hull sections or industrial press frames. Specialized facilities can even machine larger parts by segmenting them and joining with precision welding.

- How do you transport large machined parts?

Large parts are transported using flatbed trucks, cranes, and specialized trailers. For oversized components (over 12 meters), we coordinate with logistics experts to secure permits and design custom lifting fixtures to prevent damage.

- What tolerances can be achieved in large part machining?

Typical tolerances are ±0.1 mm for length and ±0.05 mm for critical features like bores. With advanced equipment and laser tracking, we can achieve ±0.02 mm on key surfaces, such as bearing seats in turbine casings.