Introduction: Why is CNC machined polycarbonate the new favorite in the engineering world?

As a high-performance engineering plastic, polycarbonate (PC) occupies an important position in the processing of precision components in electronics, automotive, medical and other industries due to its excellent impact resistance, heat resistance, and mechanical stability. The precision and flexibility of CNC machining technology perfectly match the machining needs of polycarbonate. However, many engineers will encounter problems such as cracking, deformation, and insufficient accuracy in actual operation - how to give full play to the advantages of polycarbonate processing and avoid processing pain points? This article will provide you with a set of practical guidelines that can be directly implemented from material properties, process parameters, industry applications to problem solving.

1. Polycarbonate Material Properties Demystified: Why is it Suitable for CNC Machining?

To do CNC machining well, you must first find out the "temper" of the material. The core properties of polycarbonate (PC) directly determine the choice of processing process, and here are the key parameters that senior engineers pay the most attention to:

| Feature category | Core indicators | Industry standard values | Impact on CNC Machining |

| Mechanical properties | Impact strength | 65kJ/m²(ISO 179) | Far better than ABS plastic, it is not prone to brittleness during processing, but the cutting force needs to be controlled |

| Tensile strength | 60MPa(ISO 527) | Supports the structural stability of precision parts and is suitable for high-load components | |

| Thermal performance | Thermal deflection temperature | 130℃(0.45MPa) | Withstands slight temperature rises during machining without complex cooling |

| Glass temperature | 145℃ | Avoid the processing temperature close to this value, otherwise it is easy to deform | |

| Processing characteristics | Melt index | 10g/10min(300℃/1.2kg) | Moderate fluidity for precision forming and cutting |

| Water absorption | 0.3%(23℃/24h) | It needs to be dried before processing, otherwise bubbles and cracks will appear |

Real case: An electronic equipment manufacturer once ignored the water absorption rate of PC materials and directly processed undried raw materials, resulting in surface bubbles and internal cracks in 30% of the electronic shells, resulting in a rework loss of more than 100,000 yuan. Later, the 80°C/4h drying process was used to completely solve this problem.

In short, the core advantage of PC plastic's mechanical properties is "both strength and toughness", and the heat-resistant properties of engineering plastics make them less likely to soften during high-speed cutting, which is the key to making them the preferred material for CNC precision machining.

2. Key points of CNC machining technology and technology: full analysis of parameters, tools, and techniques

After mastering the material properties, precise control of the processing process is the core of success or failure. Here's a hands-on dry product for polycarbonate, from parameter setting to tool selection:

1. Core processing parameter recommendation (measured optimization version)

Different equipment and part requirements will vary slightly, but the following parameters can be used as initial settings (based on φ10mm end mills):

| Processing method | Cutting speed (m/min) | Feed Rate (mm/tooth) | Depth of Cutting (mm) | Cooling method |

| CNC milling polycarbonate | 120-150 | 0.15-0.25 | 1-3 (Roughing) | Air cooling + micro cutting fluid |

| 180-220 | 0.08-0.12 | 0.2-0.5 (Finishing) | Air-cooled only | |

| PC Plastic CNC Machining (Drilling) | 80-100 | 0.1-0.15 | 2-3mm each time | Intermittent feed + air cooling |

Key reminder: At the heart of plastic CNC machining parameters is "high speed and low load" – avoiding material tearing due to high feeds while controlling the cutting temperature to prevent softening and deformation. An automotive parts factory increased the cutting speed from 100 m/min to 180 m/min, increased machining efficiency by 40%, and reduced the surface roughness from Ra1.6 μm to Ra0.8 μm.

2. Tool selection and cutting skills

- Tool material: Prefer carbide tools (TiAlN is recommended for coating) to avoid the decline in machining accuracy caused by insufficient wear resistance of high-speed steel tools. For precision machining plastics, the cutting edge of the tool needs to be passivated (edge radius 0.02-0.05mm) to prevent scratching the surface of the material.

- CNC Cutting Tips:

- The grinding method is used to reduce the burrs caused by material rebound;

- Deep cavity machining adopts layered cutting, and the depth of each layer does not exceed 1/3 of the tool diameter;

- Avoid cutting the same position continuously for a long time to prevent the local temperature rise from being too high.

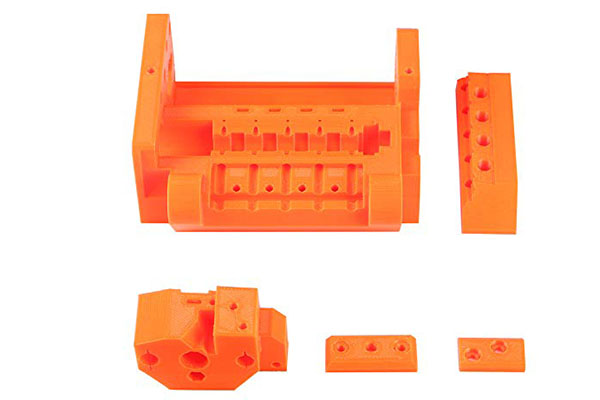

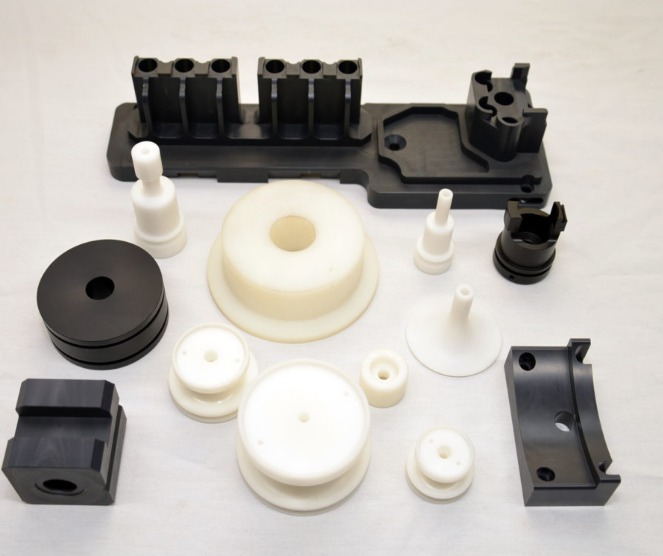

3. Design applications and industry cases: These scenarios are being widely used

The combination of polycarbonate's excellent properties and CNC machining precision allows it to be used on a large scale across multiple industries, here are 3 typical cases:

1. Electronic enclosure CNC machining

Case: A laptop enclosure for a consumer electronics brand using CNC milling + engraving from a 3mm thick PC sheet. Design essentials include:

- Reserve an assembly clearance of 0.2mm to accommodate the slight shrinkage of PC materials;

- The corners are designed with R3mm rounded corners, which take advantage of the characteristics of impact-resistant plastics to improve drop resistance.

- The surface is reserved for frosting and subsequent post-processing to enhance the feel.

The processing yield of this case reached 98.5%, and the processing time per piece was controlled at 12 minutes, and the mass production efficiency was significantly higher than that of traditional injection molding processes.

2. Medical device plastic parts

Case study: A medical device company's infusion set flow controller has a CNC-machined PC spool as its core component. Because medical products have extremely high requirements for precision and cleanliness, attention should be paid to during processing:

- Food-grade PC raw materials are used, and the processing environment is a clean workshop of 10,000 levels;

- The valve spool bore tolerance is controlled at ±0.01mm, which is achieved by precision CNC lathe machining;

- Avoid using chlorine-containing cutting fluids to prevent material contamination.

The part has passed ISO 13485 medical certification and has an annual production capacity of 5 million pieces, which is a testament to the reliability of polycarbonate in the medical field.

3. Automotive plastic parts

Case: The observation window of the battery pack of a new energy vehicle is CNC cutting + edge chamfering processing of PC sheets. Design considerations:

- For heat resistance requirements (-40°C to 85°C), choose high-temperature resistant modified PC materials;

- Anti-UV coating reserves the position to improve the outdoor service life;

- The mounting hole adopts countersunk design to avoid stress concentration during assembly.

4. Surface Treatment and Post-processing: Make PC parts more valuable

For CNC machined polycarbonate parts, post-processing to improve performance and appearance, the following common processes are used:

1. Comparison of core post-processing technology

| Process name | Main role | Operational points | Applicable scenarios |

| PC plastic polished | Improves surface finish | Wool wheel + polishing paste (grit size W5-W10) with a speed of 1500-2000rpm | Transparent parts, appearance parts |

| Polycarbonate coating | Anti-scratch and UV resistant | Spray PU coating with a thickness of 20-50μm and a curing temperature of 60°C/30min | Parts for outdoor use |

| Plastic bonding and assembly | Parts spliced | Prefer UV glue (curing time 3-5s) and avoid acetone solvent glue | Precision assembly |

2. Practical precautions

- Avoid excessive force when polishing, otherwise high temperature will cause the material to turn yellow;

- Before coating, the oil stains on the surface of the parts should be cleaned, otherwise the coating will fall off;

- The sequence of post-processing of CNC machining is recommended: deburring→ cleaning→ drying→ polishing→ coating→ assembly.

Experience sharing: When a lighting company processes PC lampshades, they have been coated without drying thoroughly after polishing, resulting in pinholes in the coating. Later, the process was optimized and a drying step of 120°C/1h was added, and the problem was completely solved.

5. Common problems and effective solutions: avoid these pitfalls

The following problems are most likely to arise during the CNC machining process of polycarbonate, and the corresponding solutions are proven in practice:

1. Polycarbonate processing cracking

- Reasons: the material is not dried, the cutting force is too large, and the sharpness of the tool edge is too low;

- Solution:

- Drying before processing (80°C/4h), moisture content controlled below 0.1%;

- Reduced feed (30% reduction) with layered cutting;

- Replace the tool with a new tool or re-sharpen the tool to ensure the edge is sharp.

2. CNC machining deformation control

- Reasons: high cutting temperature, excessive clamping force, unreasonable part structure;

- Solution:

- Air cooling + intermittent cutting is used to avoid continuous processing;

- Use vacuum suction cups or elastic clamps to reduce clamping stress;

- When designing, stiffeners should be added to avoid large areas of thin-walled structures.

3. Machining accuracy improvement skills

- Core measures:

- The tool should be preheated for 10 minutes before reprocessing to reduce the impact of thermal expansion and contraction.

- Pause for 30 minutes before finishing to stabilize the temperature of the machine and part.

- CNC equipment with closed-loop control system, the repeat positioning accuracy is controlled within ±0.005mm.

6. Yigu Technology's views

As a technical team focusing on precision machining of engineering plastics, Yigu Technology believes that the core of CNC machining polycarbonate is "the precise matching of material properties and process parameters". With the increasing demand for precision components in 3C, automotive, medical and other industries, the market application of polycarbonate will continue to expand due to its advantages of "strength, heat resistance, and easy processing". In the future, we recommend that companies prioritize modified PC materials (such as glass fiber reinforced, flame retardant grade) and combine them with automated CNC equipment to improve efficiency. At the same time, it pays attention to the optimization of post-processing processes and further expands product application scenarios through coating, bonding and other technologies. Only by deeply integrating material cognition, process control, and post-processing technology can we truly give full play to the value of CNC machined polycarbonate.

FAQ

- Which is better for CNC machining, polycarbonate or acrylic?

A: Polycarbonate is more suitable, its impact resistance is 10 times higher than acrylic, it is not easy to crack when processed, and it has better heat resistance, making it suitable for precision parts production.

- When CNC machining PC materials, is it necessary to use cutting fluids?

Answer: A trace amount of oily cutting fluid can be used for roughing (to avoid water absorption caused by water-soluble cutting fluid), and it is recommended to use only air cooling for finishing to prevent cutting fluid residue from affecting surface accuracy.

- How can you tell if PC material is dry in place?

Answer: It can be detected by weighing method (weight difference before and after drying ≤0.1%), or observe whether bubbles and silver wire patterns appear during processing, and if so, it means that the drying is insufficient.

- How accurate can the machining of polycarbonate parts be?

A: Using precision CNC equipment and optimized processes, the dimensional tolerance can be controlled as ±0.01mm and the surface roughness Ra≤0.4μm.

- How much can the hardness of PC materials be improved after scratch-resistant surface treatment?

A: After being treated with PU coating, the surface hardness can be increased from HB to 2H (Pencil Hardness Test), which can effectively resist daily scratches.