1. Introduction

1.1 Introduce the basic concepts of VMC and HMC

In the field of precision machining, VMC (Vertical Machining Center) and HMC (Horizontal Machining Center).It is two core equipment, and many friends engaged in the processing industry will be troubled by these two when selecting models. In simple terms, the spindle of VMC is vertically arranged, the workpiece is placed horizontally during machining, and the tool cuts from top to bottom; The main axis of the HMC is horizontal, and the workpiece is usually mounted on a rotary table, and the tool completes the machining action from the side. Although both devices are used for cutting complex parts, the difference in core structure determines their applicable scenarios and machining capabilities.

1.2 Discuss the importance of the differences

Understanding the differences between VMC and HMC is crucial for enterprise production planning, cost control, and product quality. To give a real case: a small parts processing factory mistakenly handed over box parts that needed multi-faceted processing to VMC production, and the result was that it needed to be clamped and adjusted multiple times, which not only had low production efficiency, but also had a scrap rate of up to 15%; Later, it was replaced with HMC processing, and multi-sided processing could be completed in one clamping, and the scrap rate was directly reduced to less than 2%. In addition, the procurement cost and operation and maintenance cost of the two are quite different, and the entry cost of VMC is usually 30%-50% lower than that of HMC of the same specification. On the other hand, using VMC to undertake complex multi-sided processing will affect production efficiency and delivery time.

2. Definition and characteristics of VMC

2.1 Full name and function of VMC

VMC stands for Vertical Machining Center, that is, vertical machining center, its core function is to drive the tool through the vertical spindle to mill, drill, boring, tapping and other cutting processes on the workpiece. It is equipped with an XYZ three-axis linkage system, and some high-end models also support four-axis linkage, which can realize the processing of complex curved surfaces. The structure of VMC is relatively simple, the headstock is fixed on the column, the worktable can move along the X and Y axes, and the spindle is lifted and lowered along the Z axis, which is intuitive and easy to understand, and it is easy for novices to get started.

2.2 Application scenarios of VMC

VMC is suitable for machining single-sided or simple multi-faceted parts, and common application scenarios include:

- Electronics industry: milling of mobile phone shells and computer chassis parts;

- Mold industry: cavity and core processing of simple plastic molds;

- Auto parts industry: processing of flat parts such as automobile dashboard brackets and door hinges;

- General machinery: drilling and tapping processes for small gears, flanges and other parts.

For example, an electronics factory produces mobile phone middle frames, using VMC for milling and chamfering, with its highly rigid spindle and precise positioning system, it can achieve a machining accuracy of ±0.005mm, which fully meets the precision requirements of electronic parts.

2.3 Advantages and disadvantages of VMC

The advantages of VMC are very prominent: first, the procurement and operation and maintenance costs are low, the market price of entry-level VMC is about 15-300,000 yuan, and the daily maintenance only needs to regularly check the spindle lubrication and guide rail cleaning, and the maintenance cost is only 2-30,000 yuan per year; second, the operation threshold is low, and ordinary operators can operate independently after 1-2 months of training; Third, the footprint is small, and the VMC with the same processing stroke saves about 40% of the workshop space compared with the HMC.

Its disadvantages are also obvious: first, multiple clamping is required when processing multi-faceted parts, which is not only time-consuming, but also easy to affect the machining accuracy due to clamping errors; second, the chip removal effect is poor, and the iron filings generated by cutting are easy to accumulate on the worktable and the surface of the workpiece, and additional chip removal devices are required, otherwise it will scratch the surface of the workpiece; Third, the spindle has a single force direction, and the stability is not as good as that of HMC when processing large and heavy parts.

3. Definition and characteristics of HMC

3.1 Full name of HMC and its function

HMC stands for Horizontal Machining Center, that is, horizontal machining center, the core feature is the horizontal arrangement of the spindle, usually equipped with a rotary table (4th or 5th axis). Its core function is to realize the multi-faceted and multi-process integrated processing of parts, through the rotation of the rotary table, it can drive the workpiece to switch different processing surfaces, and with the cutting action of the spindle, it can complete the milling, drilling, boring and other processes of multiple surfaces in one clamping. HMCs have more complex transmission systems and support structures, usually driven by servo motors, with higher positioning accuracy and repeatable positioning accuracy.

3.2 Application scenarios of HMC

HMC is mainly used for machining complex and multi-faceted parts that require high-precision integrated machining, and common application scenarios include:

- Automobile manufacturing industry: core components processing such as engine blocks, gearbox housings, and crankshafts;

- Aerospace industry: processing of high-precision parts such as aircraft landing gear parts and engine blades;

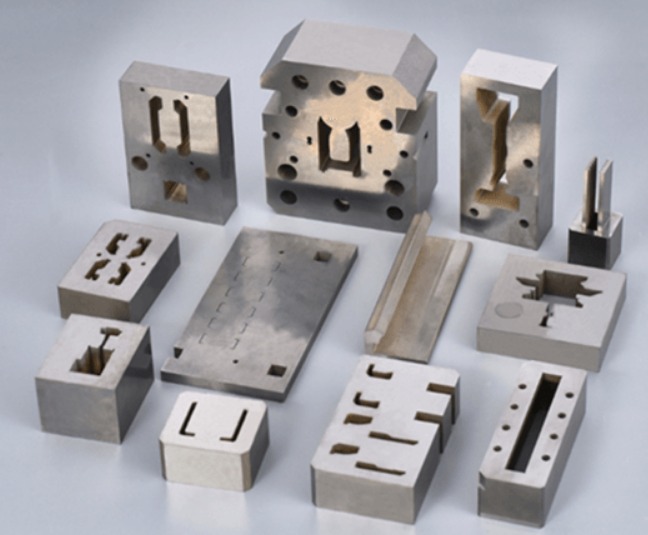

- Construction machinery industry: hydraulic valve blocks, excavator slewing bearings and other complex box parts processing;

- High-end equipment manufacturing: processing of shells and core transmission components of precision instruments.

Taking an automobile engine factory as an example, the engine block produced by it needs to process multiple faces of hole system and plane, after using HMC processing, one clamping can complete all processes, the processing efficiency is more than 60% higher than that of traditional VMC, and the position accuracy of the hole system can be controlled within ±0.003mm, meeting the strict requirements of engine core components.

3.3 Advantages and disadvantages of HMC

The core advantages of HMC: First, it has high processing efficiency, suitable for batch processing of complex and multi-faceted parts, and can complete multi-process processing with one clamping, reducing clamping time and error; second, the chip removal effect is good, the iron filings generated by the horizontal spindle can fall naturally with the help of gravity, without the need for additional complex chip removal devices, which can effectively protect the surface of the workpiece; third, the processing stability is strong, the spindle is arranged horizontally, the force is more uniform, and the rigidity and stability are better than VMC when processing large and heavy parts; Fourth, the degree of automation integration is high, and it is easy to cooperate with robots and automatic loading and unloading systems to achieve unmanned production.

The disadvantages of HMC are mainly high cost: first, the procurement cost is high, the market price of entry-level HMC is about 50-1 million yuan, and high-end models can reach millions of yuan; second, the operation and maintenance cost is high, and the complex structure requires professional maintenance personnel, and the annual maintenance cost is about 5-80,000 yuan; third, the operation threshold is high, and the operating tools need to have rich programming and debugging experience, and the training period is as long as 3-6 months; Fourth, it occupies a large area and has high requirements for workshop space.

4. Comparison of VMC vs HMC

4.1 Functional differences

The core functional differences between VMC and HMC focus on machining dimensions and process integration capabilities, as follows:

| Contrast dimensions | VMC (Vertical Machining Center) | HMC (Horizontal Machining Center) |

|---|---|---|

| Spindle layout | Vertical layout | Horizontal layout |

| Processing dimensions | It mainly supports XYZ three-axis, and some can expand four-axis | Generally supports four-axis/five-axis linkage, and the processing dimensions are richer |

| Process integration capabilities | Single process or simple multi-process, multi-sided processing requires multiple clamping | Multi-process integration, one clamping can complete multi-faceted and multi-process processing |

| Automation adaptability | Automation integration is difficult, and most of them are semi-automatic production | It is easy to cooperate with the automation system to achieve fully automated and unmanned production |

4.2 Performance Differences

From the comparison of the three core performance dimensions of machining accuracy, efficiency and stability, the differences between the two are obvious:

- Machining accuracy: The positioning accuracy of ordinary VMC is usually ±0.005-0.01mm, and high-end VMC can reach ±0.003mm; The positioning accuracy of HMC is generally ±0.003-0.005mm, and high-end models can reach ±0.001-0.002mm, which has more obvious precision advantages in the processing of complex parts.

- Machining efficiency: For simple single-sided parts, VMC and HMC have similar efficiency; For complex multi-faceted parts, HMC is 3-5 times more efficient than VMC due to reduced multiple clamping and adjustment times.

- Stability: VMC has good stability when processing small and light parts, but when processing large and heavy parts, the spindle is prone to deformation under vertical force; The HMC spindle is subjected to uniform horizontal force, and with a more rigid bed structure, it is more stable when machining large and heavy parts.

4.3 Differences in applicable scenarios

VMC and HMC are clearly divided into applicable scenarios, and the core depends on part complexity, batch and cost budget, which can be specified in the following principles:

When processing simple single-sided/few-sided parts, small batches, and limited cost budget, VMC is preferred. HMCs are preferred when machining complex and multifaceted parts, large batch sizes, high requirements for precision and efficiency, and sufficient budgets.

Supplement the comparison of two typical scenarios: small hardware factories process simple flanges (batch of 500 pieces/month), VMC can meet the needs, and the comprehensive cost is 60% lower than HMC; When processing engine blocks (batch sizes of 10,000 pieces/month) in large auto parts factories, HMC must be selected to ensure processing efficiency and accuracy, while reducing labor costs.

5. Conclusion

5.1 Summarize differences between VMC and HMC

To sum up, the core differences between VMC and HMC can be summarized as the following four points: first, the structural difference, the VMC spindle is vertical, and the HMC spindle is horizontal, which is the root cause of all differences; second, the function difference, HMC has richer processing dimensions and stronger process integration capabilities, while VMC is relatively simple; third, the performance difference, HMC is better in machining accuracy, efficiency and stability, especially suitable for complex parts; Fourth, the cost difference, the procurement and operation and maintenance cost of HMC is much higher than that of VMC.

When selecting a model, enterprises do not need to blindly pursue high-end HMCs, but should make comprehensive judgments based on the complexity, batch and cost budget of their own products: choose VMC for simple parts, small batches, and low budgets; Choose HMC for complex parts, large quantities, and high requirements. Only by correctly distinguishing and selecting the two can we achieve the optimal balance between production efficiency and cost.

Yigu Technology view

As an enterprise deeply involved in the field of precision machining equipment, Yigu Technology believes that VMC and HMC are not substitutions, but complementary relationships. At present, the manufacturing industry is transforming to intelligence and high precision, and small and medium-sized enterprises can first consolidate their basic production capacity through VMC, and then gradually introduce HMC with business upgrades. Large enterprises can achieve efficient coverage of simple and complex parts through the combined layout of "VMC+HMC". In the future, the integration trend of the two will be more obvious, such as VMC with rotary workbench, miniaturized HMC and other models will continue to emerge to better meet the segmented needs of different scenarios. The core of enterprise selection is to match its own production needs, rather than simply pursuing high-end equipment.

FAQ

Q1: Which is more accurate in machining VMC or HMC?

Overall, HMC has higher machining accuracy. The positioning accuracy of ordinary HMCs can reach ±0.003-0.005mm, and high-end models can even reach ±0.001-0.002mm; The positioning accuracy of ordinary VMCs is mostly ±0.005-0.01mm, and only high-end VMCs can approach the accuracy level of ordinary HMCs. However, for simple parts machining, VMC's precision is already sufficient.

Q2: Is it suitable for novice companies to purchase VMC or HMC first?

Novice enterprises give priority to purchasing VMCs. On the one hand, the procurement and operation and maintenance costs of VMC are lower and the financial pressure is small; On the other hand, VMC has a low threshold for operation and is easy for novice operators to get started, which can help enterprises quickly establish production capacity. When the business of the enterprise is stable and needs to process complex parts, consider introducing HMC.

Q3: Do I have to use HMC to process box parts?

Not necessarily. If it is a simple box part (only 1-2 sides need to be processed), VMC can be used for multiple clamping processing; However, if it is a complex box part (3 or more needs to be processed, and the hole system position accuracy is required), it is recommended to use HMC, which can be completed in one clamping, which can effectively ensure accuracy and efficiency.

Q4: What is the difference in maintenance focus between VMC and HMC?

The maintenance of VMC focuses on spindle lubrication and chip evacuation systems, and regular inspection of spindle oil quality, cleaning of rails and workbench filings; The maintenance of the HMC focuses on the rotary table, hydraulic system, and transmission system, and the positioning accuracy of the rotary table, the cleanliness of the hydraulic oil, and the wear of the transmission gears need to be checked regularly.