In the world of product design and manufacturing, bridging the digital and the physical is critical. A CNC model serves as this essential bridge, transforming a virtual concept into a precise, tangible object for validation, testing, and presentation. Unlike rapid prototypes, CNC models are prized for their superior accuracy, material integrity, and surface finish, often serving as the final proof-of-concept before mass production. This article delves into the intricacies of CNC models, exploring their creation, optimization, and finishing, providing a comprehensive guide for engineers and designers seeking to leverage this powerful technology for flawless product development.

What is a CNC Model?

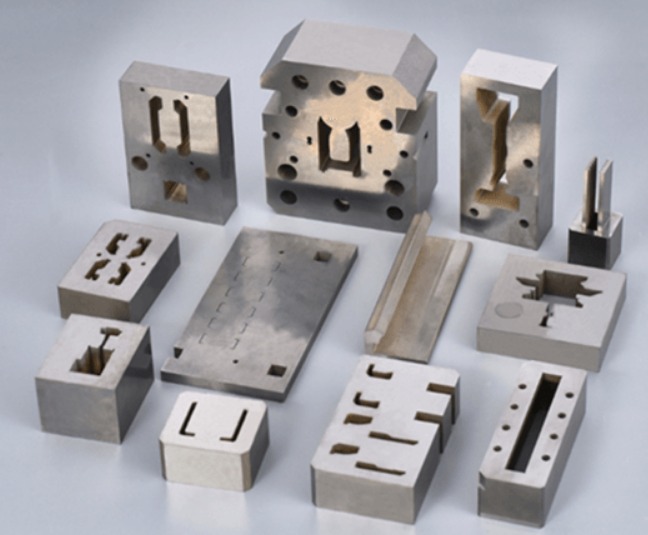

A CNC model is a physical representation of a product or component, machined directly from a solid block of material using Computer Numerical Control (CNC) technology. It starts life as a precise digital 3D model, typically a CAD file. This file's instructions guide cutting tools to subtractively remove material with exceptional precision and repeatability. The result is a high-fidelity part that can be functionally tested, used for fit checks, or presented as a high-end sales sample.

How Do CNC Models Differ from Traditional Prototypes?

While both are prototypes, CNC models occupy a distinct niche. They differ significantly from methods like 3D printing (FDM, SLA) in several key aspects.

- Material Properties: CNC models are made from real, engineering-grade materials—metals, solid plastics, woods. A CNC-machined aluminum housing, for instance, has the identical thermal conductivity, strength, and feel as the final production part. A 3D-printed version in resin or plastic filament cannot match this.

- Accuracy and Tolerance: CNC machining achieves tolerances as tight as ±0.025mm or better, surpassing most desktop 3D printers. This is non-negotiable for components that must mate perfectly with existing assemblies.

- Surface Finish: Directly from the machine, a CNC model has an inherently superior surface quality. With minimal post-processing, it can achieve a production-ready aesthetic.

- Cost & Speed for Low Volumes: For one-off or very low-volume prototypes of dense, solid parts, CNC can be faster and more cost-effective than setting up molding tools. However, for highly complex, hollow geometries, 3D printing often holds the advantage.

Table: CNC Models vs. Traditional 3D Printed Prototypes

| Feature | CNC Model | FDM/SLA 3D Printed Prototype |

|---|---|---|

| Primary Process | Subtractive Manufacturing | Additive Manufacturing |

| Material Reality | Real, isotropic engineering materials | Plastic polymers, resins (often anisotropic) |

| Dimensional Accuracy | Very High (±0.025mm typical) | Moderate to Good (±0.1-0.5mm typical) |

| Strength & Durability | Equal to final production material | Material-dependent, often lower |

| Best For | Functional testing, fit checks, high-end visuals | Form studies, very complex geometries, rapid iteration |

Which Software Creates the Most Accurate CNC Models?

Accuracy begins with the digital twin. The most suitable software depends on the industry and part complexity.

- Engineering & Mechanical Design: SolidWorks, Autodesk Inventor, and Siemens NX are industry standards. They excel at creating parametric, feature-based models with precise geometric constraints and history trees. Their strength lies in modeling manufacturable parts with clear design intent, making the translation to CNC toolpaths logical.

- Complex Surfacing & Automotive/Aerospace: CATIA and Creo (Pro/ENGINEER) are dominant for Class-A surfacing and managing extremely complex assemblies. They provide unparalleled control for aerodynamic or ergonomic forms where surface continuity is critical.

- Aesthetic & Organic Design: Rhino 3D, especially with its Grasshopper plugin, is powerful for free-form, organic shapes common in architecture, jewelry, and consumer product design. Its NURBS-based modeling ensures smooth, accurate surfaces.

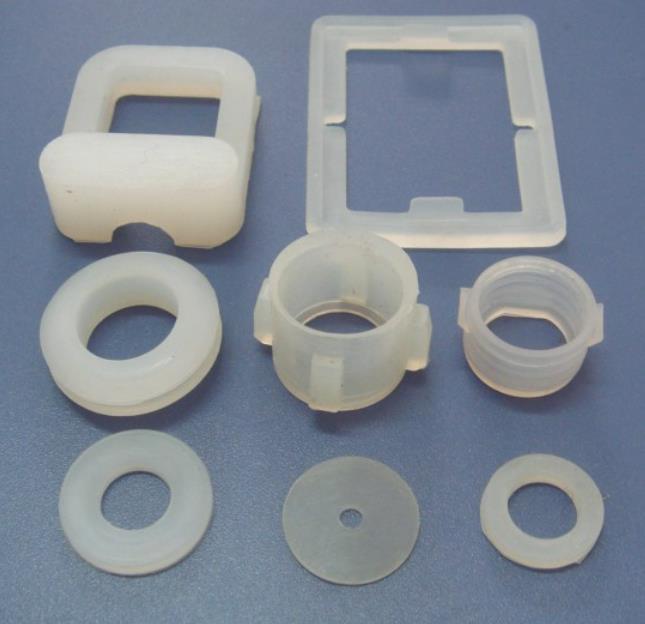

What Materials Work Best for CNC Model Making?

The choice of material is driven by the model's purpose: form, fit, or function.

- For Visual & Fit Models (Non-Functional):

- Machinable Wax & Urethane Boards: Ideal for intricate details and easy machining. They are soft, produce fine features, and are perfect for mold patterns.

- Polyurethane (PU) Boards: Like Tufnol or Duraplex, they offer a good balance of machinability and a plastic-like finish. Available in various grades simulating ABS or Polypropylene.

- For Functional & Load-Bearing Models:

- Aluminum (6061, 7075): The workhorse of CNC prototyping. Offers an excellent strength-to-weight ratio, good machinability, and can be anodized or painted. Used for enclosures, brackets, and mechanical parts.

- POM (Delrin): A premium engineering plastic known for high stiffness, low friction, and excellent dimensional stability. Perfect for gears, bearings, and sliding parts.

- Stainless Steel (304, 316): Used when corrosion resistance, high strength, or high-temperature performance is required for testing.

How to Optimize CAD Data for CNC Model Production?

A perfect CAD model does not always mean a manufacturable CNC model. Optimization is key.

- Ensure "Watertight" Geometry: The model must be a single, cohesive solid or surface body with no gaps, overlaps, or stray edges. Use the "Check Entity" or "Validation" tools in your CAD software.

- Define Clear Tolerances: Apply realistic geometric dimensioning and tolerancing (GD&T) in the drawing or model properties. This guides the machinist on critical features.

- Consider Tool Access: Design with realistic tool diameters in mind. Avoid designing internal sharp corners smaller than the available cutting tools (e.g., a 1mm corner radius requires a ≤2mm end mill).

- Simplify Where Possible: Remove unnecessary cosmetic textures, decals, or extremely fine details that are smaller than the CNC tool's capability. These can be added later via etching or laser marking.

- Export in a Neutral Format: While native CAD files are best, a STEP (.stp) or Parasolid (.x_t) file is the most reliable neutral format for transferring 3D geometry between different CAM software without losing data.

What Scaling Challenges Arise in CNC Model Machining?

Creating scale models (e.g., a 1:10 architectural model) introduces unique hurdles.

- Feature Resolution: Small-scale details can become smaller than the minimum tool diameter. A window frame detail that is 20mm wide at full scale becomes only 2mm at 1:10 scale, potentially requiring specialized micro-tools.

- Tool Deflection & Breakage: At reduced scales, the forces on tiny tools are proportionally high, leading to deflection (reducing accuracy) or breakage. Machining strategies must use lighter cuts and higher spindle speeds.

- Material Grain & Texture: The inherent grain of a material like wood or the texture of a foam board can become disproportionately large and visually dominant on a small model, ruining the aesthetic.

Solution: From a project for an architectural firm, we needed a 1:50 scale model of a complex facade. We switched from the specified timber to a fine-grained modeling board (PU foam) and used a 0.5mm diameter ball-nose end mill with high-speed machining (HSM) toolpaths. This allowed us to capture the delicate mullion details without tool failure.

How to Achieve Fine Surface Details on a CNC Model?

Achieving meticulous surface details requires a combination of strategic machining and tool selection.

- Toolpath Strategy: Use a roughing pass with a larger tool to remove bulk material, followed by multiple finishing passes with progressively smaller tools. Contour-parallel or scallop-height finishing toolpaths provide consistent surface quality.

- Tool Selection: Ball-nose end mills are essential for 3D contours and organic shapes. For very fine details like engraved text or textures, V-bit engraving tools or micro end mills (down to 0.1mm) are used.

- Machine Rigidity & Speed: A high-precision, rigid CNC machine with a high-frequency spindle is necessary to run tiny tools at the required RPMs (often 20,000+ RPM) without vibration, which causes chatter and ruins surface finish.

What Post-Processing Steps Refine a CNC Model?

The journey from machined part to polished model is critical.

- Support Removal & Deburring: Carefully remove any tabs or support structures used during machining. Use hand files, scrapers, or sandpaper to remove all sharp edges (burrs).

- Sanding & Polishing: Begin with coarse grit sandpaper to remove tool marks, moving progressively to finer grits (up to 2000+ grit). For plastics and metals, mechanical polishing with compounds can achieve a mirror-like finish.

- Priming and Painting: Apply a filler primer to reveal any microscopic imperfections for final sanding. Use model-specific paints applied in light, even coats. For metals, anodizing or powder coating provides a durable, professional finish.

- Adding Final Details: Apply decals, labels, or cosmetic textures using pad printing or waterslide decals. For metallic logos, electroplating or physical vapor deposition (PVD) coating on specific areas adds a premium touch.

Conclusion

A CNC model is far more than just a prototype; it is a tangible validation of design, engineering, and manufacturability. By understanding the entire ecosystem—from selecting the right CAD software and engineering-grade materials to optimizing geometry for machining and applying meticulous post-processing—teams can leverage CNC models to de-risk product development, impress stakeholders, and pave a smoother path to successful production. In an era of digital design, the physical truth offered by a precision CNC model remains indispensable.

FAQ

- What file format is best for CNC machining?

While native CAD files (e.g., .SLDPRT, .IPT) are ideal, STEP (.stp) and IGES (.igs) are the most universally accepted neutral formats that preserve solid geometry accurately. - Can a CNC model be made from the same material as mass production?

Yes, this is one of the primary advantages of CNC prototyping. You can machine the model from the exact aluminum, steel, or plastic specified for production, ensuring identical mechanical and thermal properties. - How expensive is a CNC model compared to a 3D-printed one?

Cost depends on size, material, and complexity. For simple, small parts, 3D printing is often cheaper. For larger, dense parts or those requiring engineering materials and tight tolerances, CNC can be comparable or even more cost-effective, especially when material properties are considered. - What is the typical lead time for a CNC model?

Lead time varies from 2-5 days for simple models to 2-3 weeks for highly complex, large, or finely finished pieces. It includes CAD preparation, CAM programming, machining, and post-processing.

Contact Yigu for Custom Manufacturing.

At Yigu Technology, we view the CNC model not merely as a step in the process, but as the cornerstone of successful manufacturing. It is the final, unforgiving test of a design's integrity. Our experience has shown that investing in a high-fidelity CNC prototype invariably saves substantial time and cost downstream by exposing fitment issues, material behavior, and machining challenges early. We combine state-of-the-art 5-axis CNC capabilities with deep engineering expertise to not just machine your model, but to collaboratively optimize your design for manufacturability (DFM). Let us help you transform your digital vision into a perfect physical reality. Reach out to discuss your next project.