Introduction

What is a CAD Model?

A CAD (Computer-Aided Design) model is a digital representation of a physical object or system, created using specialized CAD software. This model can be two-dimensional (2D) or three-dimensional (3D), depending on the complexity of the design and the requirements of the project. In 2D CAD models, you can create precise technical drawings, such as floor plans, blueprints, or mechanical part diagrams. These are often used for projects where a detailed view of a single plane or surface is sufficient. For example, in architectural design, 2D CAD models can represent the layout of rooms, the position of walls, doors, and windows in a building.

On the other hand, 3D CAD models are more comprehensive, as they add depth to the design, allowing for a more realistic visualization of the object from all angles. They are widely used in various industries like automotive, aerospace, and product design. For instance, when designing a car, a 3D CAD model can accurately represent the shape of the body, the interior components, and even simulate how different parts interact with each other.

CAD models are not just simple digital drawings; they contain a wealth of information, including geometric data (such as dimensions, shapes, and positions of components), material properties, and sometimes even information about the manufacturing process. This makes them an essential tool in modern design and engineering processes.

Why Design a CAD Model?

Designing a CAD model offers numerous advantages that have revolutionized the design and manufacturing industries.

Enhanced Design Precision: CAD software allows designers to input exact measurements and specifications, minimizing human error that is common in manual drafting. For example, in the design of a microchip, where the smallest deviation can lead to significant malfunctions, CAD models ensure that every circuit and component is placed with extreme accuracy. The precision of CAD models also enables designers to create complex shapes and geometries that would be nearly impossible to achieve by hand.

Accelerated Design Process: With CAD, designers can quickly make changes to their designs. Instead of having to redraw an entire design by hand when a modification is needed, a simple adjustment of parameters in the CAD software can update the entire model instantaneously. This rapid iteration speeds up the design process significantly. For instance, in the development of a new smartphone, designers can experiment with different shapes, sizes, and button placements in a CAD model within a short period, exploring multiple design concepts before finalizing one.

Cost Reduction: By identifying and rectifying design flaws in the virtual CAD model stage, companies can avoid costly mistakes during the physical production phase. In large - scale manufacturing, such as in the construction of an aircraft, a design error discovered after production has started can result in substantial rework costs. CAD models help in early detection of issues like component interference, ensuring that the final product is produced with fewer errors and at a lower cost.

Improved Visualization and Communication: A 3D CAD model provides a clear and realistic representation of the final product. This is beneficial for both the design team and clients. Designers can view the model from different angles, zoom in on details, and even create animations to demonstrate how a product will function. For clients, a 3D CAD model offers a better understanding of what the final product will look like, making it easier to provide feedback and approvals. For example, an interior designer can use a 3D CAD model to show a client how a redesigned living room will look, complete with furniture, lighting, and color schemes.

Easier Collaboration: CAD models can be easily shared among team members, regardless of their physical location. Multiple designers, engineers, and other stakeholders can work on the same project simultaneously, accessing and modifying the CAD model in real - time. This seamless collaboration improves the efficiency of the design process and ensures that everyone is working towards the same goal. In the development of a large - scale infrastructure project, such as a bridge, civil engineers, structural engineers, and architects can all contribute to the CAD model, sharing their expertise and ensuring the project's success.

Steps to Design a CAD Model

Step 1: Define the Requirements

Before starting any CAD design project, it is crucial to clearly define the requirements. This includes understanding the product's function, its intended use, and any specific performance criteria. For example, if you are designing a bicycle frame, you need to consider factors like load - bearing capacity, the type of riding it is designed for (mountain, road, etc.), and ergonomic requirements.

Size limitations also play a significant role. In a smartphone design, the overall dimensions must fit comfortably in a user's hand while accommodating all the internal components such as the battery, motherboard, and camera. Additionally, the choice of materials is essential. Different materials have different properties like strength, weight, and cost. Aeronautical components often use lightweight yet strong materials like titanium or carbon fiber to reduce weight and increase fuel efficiency.

To gather these requirements, you can conduct market research, study similar products in the market, and communicate closely with clients or end - users. Interviews, surveys, and focus groups can provide valuable insights into user needs and preferences.

Step 2: Select the Right CAD Software

Choosing the appropriate CAD software is a key decision. Here are some popular CAD software options and their features:

| CAD Software | Features | Suitable for | Approximate Price (Annual Subscription) |

| AutoCAD | Widely used for 2D drafting. It has a large library of pre - defined symbols and tools for precise 2D drawing. Also has basic 3D modeling capabilities. | Architecture, civil engineering, mechanical design (2D plans) | $1,775 |

| SolidWorks | Specializes in 3D mechanical design. It offers parametric modeling, which allows for easy modification of designs by changing parameters. Good for assembly design and interference checking. | Mechanical engineering, product design | $4,195 |

| CATIA | Known for its high - end 3D modeling and simulation capabilities. It can handle complex surface modeling, making it ideal for automotive and aerospace industries. | Aerospace, automotive, shipbuilding | Starting from around $10,000 |

The choice of software depends on your specific needs, budget, and the complexity of your projects. If you are mainly doing 2D architectural drawings, AutoCAD might be sufficient. However, for complex 3D mechanical designs, SolidWorks or CATIA could be more suitable.

Step 3: Create a Sketch

Sketching is the initial step in the CAD design process. It serves as a rough draft of your final design, allowing you to explore different ideas and concepts quickly. A sketch helps in visualizing the basic shape, layout, and dimensions of the object. For instance, when designing a furniture piece, you can start with a simple 2D sketch to determine the overall shape of the tabletop, the number and position of legs, and their relative proportions.

In CAD software, you can use basic drawing tools like lines, circles, rectangles, and arcs to create the sketch. You don't need to be overly precise at this stage; the goal is to get your ideas down on the digital canvas. This sketch will form the foundation for the more detailed 3D modeling that follows.

Step 4: 3D Modeling

Once you have a satisfactory sketch, you can start the 3D modeling process. This involves converting the 2D sketch into a three - dimensional object. There are several techniques for 3D modeling:

- Extrusion: This is used to add depth to a 2D shape. For example, if you have a circular 2D sketch, extruding it will create a cylinder.

- Revolution: By rotating a 2D profile around an axis, you can create objects with rotational symmetry, such as a shaft or a vase.

- Lofting: Lofting is useful when you want to create a 3D object by connecting multiple 2D cross - sections. It can be used to create complex shapes like the body of an airplane.

When performing these operations, it's important to pay attention to details such as the orientation of the axes, the accuracy of the dimensions, and the smoothness of the transitions between different parts of the model. Using snap and grid features in the CAD software can help improve the accuracy of your 3D modeling.

Step 5: Apply Materials and Textures

Adding materials and textures to your 3D model makes it more realistic and visually appealing. Different materials have unique optical and physical properties that can be simulated in CAD software. For example, a metal material will have a different reflectivity and color compared to a plastic material.

To apply materials, you can use the material libraries provided in the CAD software. These libraries usually contain a wide range of materials such as aluminum, steel, wood, and various types of plastics. You can also customize the material properties to match your specific requirements.

Textures can further enhance the realism of the model. A wooden texture can make a model look like it's made of real wood, with grain patterns and imperfections. Some CAD software allows you to import custom textures, giving you even more control over the appearance of your model. Here is a simple comparison of how a cube looks with different materials:

Step 6: Assembly and Interference Checking

If your design consists of multiple components, you need to assemble them in the CAD environment. Assembly in CAD allows you to simulate how the different parts fit together in the real world. This is an important step to ensure that the design is feasible and that all components can be properly assembled.

After assembling the components, it's crucial to perform interference checking. Interference occurs when two or more components occupy the same space in the assembly. For example, in the design of an engine, if the piston and the valves are not properly designed, they could interfere with each other during operation.

CAD software usually has built - in tools for interference checking. These tools can quickly identify areas of interference and provide information on which components are involved. Once an interference is detected, you can go back to the design and make adjustments to fix the problem. For example, in a recent project where we were designing a complex robotic arm, interference checking revealed that a newly added sensor was colliding with one of the moving joints. By modifying the position of the sensor in the CAD model, we were able to eliminate the interference before starting the physical production.

Step 7: Analysis and Simulation

CAD software also offers powerful analysis and simulation capabilities. You can use these features to test the performance of your design under different conditions without having to build a physical prototype.

- Structural Analysis: This type of analysis helps you determine how your design will respond to different loads. For example, if you are designing a bridge, you can use structural analysis to calculate the stress and strain on different parts of the bridge under the weight of traffic and environmental forces.

- Fluid Analysis: Fluid analysis is useful when dealing with designs that involve the flow of fluids, such as pipes, ducts, or the aerodynamics of a vehicle. It can help you optimize the design to reduce pressure drops, improve flow efficiency, or analyze the aerodynamic drag of a car.

Based on the analysis and simulation results, you can make informed decisions to optimize your design. If the analysis shows that a particular part of the design is experiencing high stress, you can modify the shape, thickness, or material of that part to improve its strength.

Step 8: Finalize and Document the Design

Once you are satisfied with the design after all the previous steps, it's time to finalize and document it. Documentation is an essential part of the design process as it provides a record of the design decisions, specifications, and manufacturing instructions.

- Design Specification: This includes details about the product's function, performance requirements, materials used, and any relevant standards or regulations that the design must comply with.

- Technical Drawings: Create detailed 2D technical drawings with accurate dimensions, tolerances, and annotations. These drawings are used by manufacturers to produce the physical product.

- Bill of Materials (BOM): A BOM lists all the components required to build the product, including their part numbers, descriptions, and quantities.

Proper documentation ensures that everyone involved in the production process, from manufacturers to quality control teams, has a clear understanding of the design requirements. It also serves as a reference for future modifications or improvements to the design.

Yigu Technology's Perspective

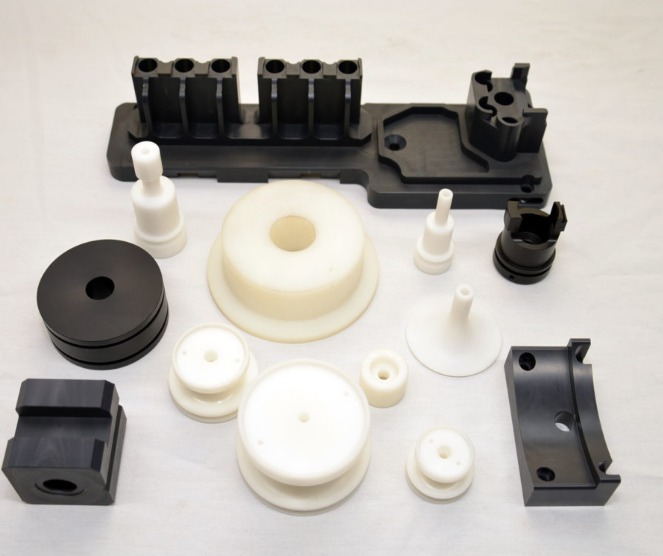

As a non - standard plastic and metal products custom supplier, Yigu Technology deeply understands the significance of CAD models in the manufacturing process.

In our experience, a well - designed CAD model is the bridge that seamlessly connects the design concept with the actual production. By integrating design and manufacturing from the CAD model stage, we can significantly enhance production efficiency. For example, when designing a custom - made plastic housing, we use CAD models to accurately define the shape, dimensions, and wall thickness. This allows us to directly transfer the design data to our manufacturing equipment, reducing the need for manual measurements and interpretations, which in turn minimizes errors during production.

CAD models also play a crucial role in optimizing our production processes. Through the interference checking and analysis functions in CAD software, we can identify potential design flaws early on. In a recent project involving the production of a complex metal - plastic composite component, CAD - based interference checking revealed that the initial design of the plastic insert would cause problems during the injection - molding process due to its interaction with the metal frame. By modifying the CAD model, we were able to adjust the design of the plastic insert, ensuring a smooth production process and high - quality end - products.

Moreover, the ability to simulate different manufacturing scenarios in the CAD environment helps us make informed decisions about material selection, manufacturing methods, and production sequences. This not only improves the quality of our products but also reduces production costs and lead times.

FAQ

Q1: What is the best CAD software for beginners?

For beginners, Fusion 360 and Tinkercad are excellent choices. Fusion 360, an integrated CAD, CAM, and CAE cloud - based platform, offers an intuitive user interface. It simplifies the design - to - production process, allowing users to handle multiple tasks in one application. Autodesk provides a wealth of online tutorials and a supportive community, which is great for those new to CAD. Tinkercad, on the other hand, is a free and easy - to - use online 3D design tool. It uses a drag - and - drop interface, making it accessible even to those with no prior CAD experience. Its library is filled with numerous pre - designed objects, enabling users to quickly assemble complex designs.

Q2: How can I improve the accuracy of my CAD model?

To enhance the accuracy of your CAD model, start with precise drawing. Use the snap and grid features in your CAD software to ensure that lines, shapes, and points are placed exactly where you intend them to be. For example, when drawing a mechanical part, snapping to grid points can help maintain the correct dimensions. Set appropriate tolerances according to the requirements of your design. If you're designing a component for a high - precision mechanical device, tight tolerances are crucial. Regularly check and verify the dimensions and geometric relationships in your model. You can use the measurement and analysis tools in the CAD software to ensure that everything is as it should be.

Q3: Can I use a CAD model for 3D printing?

Yes, you can use a CAD model for 3D printing, but there are some important considerations. First, you need to convert the CAD model to a suitable file format for 3D printing, usually STL (Stereolithography). Before conversion, ensure that your model is a watertight and manifold solid, without any holes or non - manifold geometry, as these can cause issues during 3D printing. You may also need to design support structures in your CAD model, especially for overhanging parts. These support structures help keep the model stable during the 3D printing process and can be removed later. For example, if you're 3D printing a model with a large overhanging roof, support structures will prevent the roof from collapsing during printing.