Introduction: Why is manufacturing processing technology at the heart of industrial production?

In modern manufacturing, the manufacturing machining process directly determines the precision, cost, and production efficiency of products. Whether it's the mass production of auto parts or the processing of precision components in the aerospace field, selecting the right processing technology, equipment, and parameters can increase production efficiency by more than 30% (data source: China Society of Mechanical Engineering 2023 Industry Report). This article will take you from basic classification to cutting-edge technology, take you to systematically grasp the core knowledge of manufacturing and processing technology, and solve the problems of selection and optimization in actual production.

1. The collision of tradition and modernity: the basis and classification of processing technology

1.1 The core classification logic of the processing process

Manufacturing processing technology is essentially a process of changing the shape and properties of materials through physical or chemical means, and the core can be divided into three categories:

- Subtractive manufacturing: Molding by removing materials is the most widely used process at present, including turning, milling, drilling, grinding and other traditional cutting processes;

- Additive manufacturing: commonly known as 3D printing, it is formed by stacking materials layer by layer, suitable for complex structures and customized products;

- Molding process: Through plastic deformation or flow forming of materials, such as forging, casting, injection molding, etc., the near-net forming technology can reduce the subsequent processing allowance and reduce the cost.

1.2 Application scenarios of core traditional cutting processes

| Process type: | core role | Typical applications: | Advantages: |

| turning | Machining rotary body parts | Shaft and disc parts (such as motor shafts, gear blanks) | High efficiency and suitable for mass production |

| Milling | Machining flats, grooves, and complex surfaces | Machine tool bed, mold cavity | It is flexible and can process complex shapes |

| Drilling | Machining round holes | Parts assembly holes, oil circuit holes | It is simple to operate and highly versatile |

| Grinding | High-precision surface finishing | Precision bearings, machine tool guides | The accuracy can reach IT5 level or above, and the surface roughness Ra≤0.8μm |

Case sharing: When an auto parts factory produces engine crankshafts, it adopts the combined process of "turning roughing + grinding finishing", which not only ensures mass production efficiency, but also controls the journal roundness tolerance within 0.005mm to meet the high-speed operation needs of the engine.

2. Heroes behind the scenes: processing equipment and tools

2.1 Core processing equipment: from ordinary machine tools to intelligent equipment

- Machine tool type: According to the control method, it can be divided into ordinary machine tools (manual operation) and CNC machine tools (computer numerical control), and the penetration rate of CNC machine tools in the manufacturing industry has reached 75% (data source: International Machine Tool Manufacturers Association);

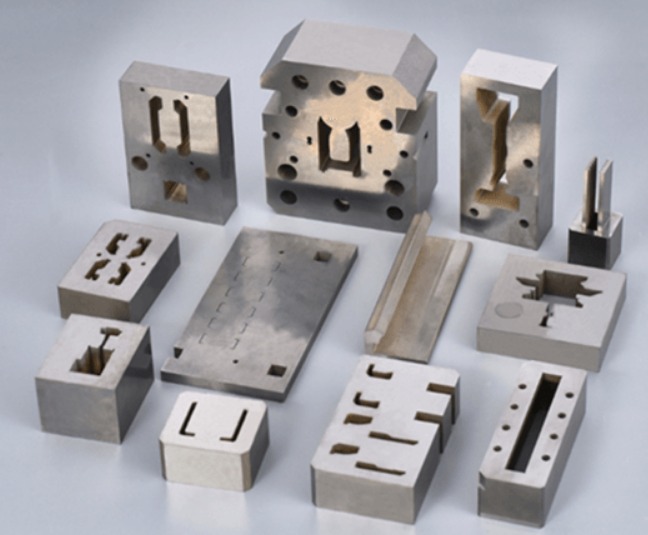

- Key equipment highlights: Multi-axis machining centers (such as five-axis linkage) can complete complex parts at one time, reducing clamping errors, especially suitable for aerospace parts; EDM EDM corrodes materials through EDM, suitable for processing hard-to-cut materials such as mold steel and carbide with a hardness of HRC60 or more.

2.2 The key role of tools and tooling

- Cutting tools: As "machining teeth", their materials directly affect the processing efficiency and quality, commonly used materials include high-speed steel, cemented carbide, PCD (polycrystalline diamond), of which PCD tools have a lifespan of 5-10 times that of cemented carbide when processing aluminum alloys;

- Fixtures and tooling: Used to fix the workpiece to ensure the consistency of machining datum, excellent fixture design can shorten the clamping time by 40% while reducing human error;

- Auxiliary components: The speed and rigidity of the spindle determine the machining accuracy, and the high-speed spindle (rotation speed ≥ 10000rpm) can achieve high-speed cutting; the tool magazine improves the automation of CNC machines and reduces tool change time.

3. Precise control: process parameters and quality control

3.1 Optimization logic of core process parameters

Cutting parameters are the key to affecting machining quality, efficiency and cost, mainly including cutting speed, feed rate, and back eating capacity:

- Too high a cutting speed will lead to aggravated tool wear, and too low a low speed will lead to low efficiency;

- The feed rate affects the surface roughness, and the smaller the feed rate, the smoother the surface, but the efficiency decreases.

- The amount of back eating cutter determines the thickness of the material removed in a single time, which needs to be reasonably selected according to the power of the machine tool and the strength of the tool.

Practical tip: When machining 45 steel, the optimal combination of parameters for carbide tools is: cutting speed 100-150m/min, feed rate 0.1-0.2mm/r, and back feed volume 2-5mm, which can achieve a balance between efficiency and tool life.

3.2 Core indicators and methods of quality control

- Key quality indicators: tolerance and fit (determine the assembly accuracy of parts), surface roughness (affect the wear resistance and sealing of parts), shape and position tolerance (such as straightness, parallelism, to ensure the function of the part);

- Inspection technology: Commonly used tools include coordinate measuring instrument (accuracy ±0.001mm), roughness meter, projector, etc.;

- Process control: SPC statistical process control monitors data fluctuations during the processing process and warns of quality risks in advance, and the defect rate is reduced from 1.2% to 0.3% after an electronic parts factory applies SPC.

4. Interaction between materials and processing: materials and processing characteristics

4.1 Influence of material properties on processing

- Metal machinability: refers to the difficulty of the material being cut, mild steel has the best machinability, stainless steel, superalloys, etc. are difficult materials;

- Material hardness: The higher the hardness, the greater the cutting resistance, and the faster the tool wears, for example, when machining hardened steel of HRC55, CBN (cubic boron nitride) tools need to be selected;

- Heat treatment impact: The hardness of the parts after quenching increases, but the machinability decreases, usually adopts the process of "machining first and then heat treatment", if it needs to be processed after heat treatment, the cutting parameters need to be adjusted.

4.2 Tool wear and chip control

- Causes of tool wear: mainly including mechanical wear and thermochemical wear, with thermochemical wear accounting for 60% of high-speed cutting;

- Countermeasures: choose the appropriate tool material, optimize the cutting parameters, and use the cutting fluid (can reduce the tool temperature by 30-50°C);

- Chip control: By adjusting the tool geometry (such as rake angle, edge inclination) and cutting parameters, it avoids chips from wrapping around the workpiece or tool, ensuring machining safety.

Example: When machining titanium alloy (difficult-to-machine material), low cutting speed (30-50m/min), large feed, high pressure cooling (pressure ≥10MPa) is adopted, and special titanium alloy tools are selected to extend the tool life from the original 20 minutes to 80 minutes.

5. Towards the future: advanced and special processing technology

5.1 Mainstream advanced processing technology

- High-speed machining: The cutting speed is 5-10 times that of traditional machining, which can improve the efficiency by 30-50%, and the processing surface quality is good, suitable for aluminum alloy and composite material processing;

- Precision machining and micromachining: precision machining accuracy up to the micron level, micromachining accuracy up to nano level, used in the fields of semiconductors and medical devices;

- Special processing technology: laser processing (cutting, welding, marking) is flexible and non-contact processing; water jet cutting (high-pressure water + abrasive) is suitable for processing brittle materials (such as glass, ceramics) and heat-sensitive materials; ultrasonic processing can process hard and brittle materials with little surface damage.

5.2 Development trend of hybrid manufacturing technology

Hybrid manufacturing technology is a combination of additive manufacturing and subtractive manufacturing, such as "3D printing molding + CNC refinement", which not only gives full play to the advantages of additive manufacturing complex structure molding, but also ensures precision through subtractive manufacturing, which is gradually widely used in the production of aerospace parts, which can reduce manufacturing costs by 20-30%.

6. Yigu Technology's views

The core value of manufacturing processes lies in "accurately matching needs and resources". With the advancement of Industry 4.0, processing technology is developing in the direction of intelligence, efficiency and greening, and enterprises need to choose the appropriate process combination based on their own product characteristics (precision requirements, batch, materials), while paying attention to the application scenarios of advanced technologies. In the future, intelligent optimization of process parameters and collaborative upgrading of equipment and tools will become the key to enhancing the competitiveness of the manufacturing industry. For enterprises, instead of blindly pursuing cutting-edge technology, it is better to first consolidate the optimization of basic processes and achieve double improvement in efficiency and quality through low-cost methods such as parameter adjustment and tool upgrades.

7. FAQ

- Q: How to choose between additive manufacturing and subtractive manufacturing?

A: Mass production of simple parts is preferential to subtractive manufacturing (high efficiency and low cost); Optional additive manufacturing for complex structures, customized products, and small-batch production; Hybrid manufacturing is available for high precision requirements.

- Q: What are the core considerations when machining difficult-to-machine materials?

A: Select special tools (such as CBN, PCD tools), reduce cutting speed, increase feed, strengthen cooling lubrication, and optimize tool geometric angles.

- Q: How can production costs be reduced through process optimization?

A: 1) Adopt near-net forming technology to reduce the processing allowance; 2) Optimize cutting parameters to improve efficiency; 3) Choose high-life tools to reduce tool change costs; 4) Apply SPC to reduce the defective product rate.

- Q: What is the core difference between a CNC machine and a regular machine?

A: CNC machine tools automatically control machining through computer programs, with high precision and efficiency, suitable for complex parts and mass production; Ordinary machine tools rely on manual operation and are suitable for simple parts, small batch production, or repairs.