The Current Landscape of Mechanical Parts Manufacturing

In the ever - evolving world of manufacturing, mechanical parts manufacturing forms the bedrock of countless industries. From the automotive sector to aerospace, and from industrial machinery to consumer electronics, the demand for high - quality mechanical parts is insatiable. However, the current landscape of mechanical parts manufacturing is a complex tapestry woven with both traditional challenges and emerging opportunities.

Traditional Manufacturing Methods and Their Limitations

For decades, traditional manufacturing methods have been the mainstay of the mechanical parts industry. These methods, such as subtractive manufacturing techniques like machining (milling, turning, drilling), have been reliable in producing parts with a certain level of accuracy. But they are not without their drawbacks.

Inefficiency in Production

Traditional manufacturing often involves multiple sequential steps. For example, in machining a complex mechanical part, the process might start with rough - cutting the raw material, followed by several finishing operations. Each step requires careful setup and adjustment of the machinery, which consumes a significant amount of time. In a study by the Manufacturing Institute, it was found that in traditional machining processes, up to 30% of the total production time is spent on non - value - added activities such as tool changes, machine setup, and workpiece handling. This inefficiency not only slows down the production rate but also increases the overall cost of production.

High Costs

The costs associated with traditional mechanical parts manufacturing are multi - faceted. First, there is the cost of raw materials. Since traditional methods often involve subtracting material from a larger block to create the desired part, there is a high rate of material waste. For instance, when manufacturing a small, intricate part from a large billet of metal, a substantial amount of the original material is cut away and discarded. Additionally, the cost of maintaining and operating the machinery is significant. Sophisticated machining tools require regular maintenance, replacement of worn - out parts, and skilled operators, all of which contribute to the high production costs. A report by McKinsey estimated that in some traditional manufacturing plants, the cost of machinery maintenance alone can account for 15 - 20% of the total production cost.

Limited Precision

Despite the advancements in traditional machining technologies, there are still limitations in achieving ultra - high precision. Minute variations in the cutting process, thermal expansion of the machinery during operation, and the wear and tear of cutting tools can all lead to deviations from the desired specifications. In industries such as aerospace, where parts need to be manufactured with tolerances in the micron range, traditional manufacturing methods often struggle to meet these stringent requirements consistently. For example, in the production of turbine blades for jet engines, even a slight deviation in the blade's shape can significantly affect the engine's performance and efficiency.

In conclusion, while traditional mechanical parts manufacturing methods have served the industry well for a long time, the inefficiencies, high costs, and limited precision are pushing manufacturers to explore innovative solutions to meet the demands of the future.

Technological Innovations Transforming the Field

In the face of the limitations of traditional manufacturing, mechanical parts manufacturers are turning to technological innovations to reshape the industry. These innovations are not only addressing the existing challenges but are also opening up new possibilities for the future.

Advanced Materials: A Paradigm Shift

The use of advanced materials in mechanical parts manufacturing represents a significant paradigm shift. High - strength, lightweight alloys, such as aluminum - lithium alloys in the aerospace industry and high - strength steel alloys in the automotive sector, are becoming increasingly popular. For example, aluminum - lithium alloys, which are used in the construction of aircraft fuselages and wings, offer a weight reduction of up to 10 - 15% compared to traditional aluminum alloys, according to a study by Boeing. This weight reduction directly translates to improved fuel efficiency, as lighter aircraft require less energy to operate. In the automotive industry, high - strength steel alloys are being used to manufacture vehicle frames. These alloys can withstand higher stress levels, enhancing the safety of the vehicle. At the same time, they can be formed into complex shapes, allowing for more aerodynamic designs.

High - performance plastics are another category of advanced materials making waves in the industry. Materials like polyetheretherketone (PEEK) are being used in applications where high - temperature resistance, chemical resistance, and excellent mechanical properties are required. PEEK has a high melting point of around 343 °C and can maintain its mechanical integrity even in harsh environments. It is being used in the production of engine components in the automotive industry and in precision parts for medical devices. The use of these advanced materials not only improves the performance of mechanical parts but also reduces the overall cost of production in the long run by increasing the lifespan of the parts and reducing maintenance requirements.

Precision Manufacturing Technologies

Advanced precision manufacturing technologies are revolutionizing the way mechanical parts are produced. Computer - numerical - control (CNC) machining has been a game - changer for decades. CNC machines can be programmed to perform highly precise operations, with tolerances as low as ±0.001 mm in some high - end applications. This level of precision allows for the production of complex parts with intricate geometries that were previously impossible to achieve with traditional machining methods. A study by the American Precision Machined Products Association found that CNC machining has increased the productivity of precision part manufacturing by up to 50% compared to traditional machining, mainly due to reduced setup times and the ability to perform multiple operations in a single setup.

3D printing, also known as additive manufacturing, is another technology that is rapidly gaining traction in the mechanical parts manufacturing industry. 3D printing allows for the creation of parts by adding material layer by layer, as opposed to subtracting material in traditional manufacturing. This technology enables the production of parts with complex internal structures, such as lattice - based designs that are both lightweight and strong. For example, in the aerospace industry, 3D - printed parts can reduce the weight of components by up to 40% while maintaining or even improving their performance. A report by Wohlers Associates estimated that the global market for 3D - printed parts in the manufacturing industry is expected to grow at a compound annual growth rate (CAGR) of over 20% in the next five years, highlighting its increasing importance.

Automation and Robotics: Streamlining Production

Automation and robotics have become integral to modern mechanical parts manufacturing. Automated production lines can operate 24/7, significantly increasing production output. For instance, in a large - scale automotive parts manufacturing plant, an automated production line can produce thousands of parts per day, compared to the limited output of a manually - operated line. A study by the International Federation of Robotics found that the use of industrial robots in manufacturing has led to a 20 - 30% increase in productivity on average.

Robots are also reducing the margin of error in production. In tasks such as precision assembly, robotic arms can achieve much higher levels of accuracy than human operators. For example, in the electronics industry, robots are used to assemble tiny components with a precision of a few microns. They can work tirelessly without fatigue, ensuring consistent quality in the production process. A case study of a smartphone manufacturing company showed that after implementing robotic assembly, the defect rate of the assembled products dropped from 5% to less than 1%. This not only improves the quality of the final products but also reduces the cost of rework and waste.

Design and Engineering Innovations

CAD/CAM/CAE: Empowering Designers

In the realm of mechanical parts design, Computer - Aided Design (CAD), Computer - Aided Manufacturing (CAM), and Computer - Aided Engineering (CAE) software have become indispensable tools.

CAD: Precision in Design

CAD software allows designers to create highly detailed 2D and 3D models of mechanical parts with precision. For example, with software like SolidWorks or AutoCAD, designers can define every dimension, curve, and surface of a part. A study by the Design Engineering Institute found that CAD - based design processes can reduce design errors by up to 70% compared to traditional manual drafting. This is because CAD software enforces geometric constraints and allows for easy modification of designs. If a designer needs to change the dimensions of a part, they can simply input the new values, and the software will automatically update the entire model, including all related views and drawings.

CAM: Bridging Design to Production

CAM software takes the design created in CAD and generates the instructions for manufacturing processes. It is closely integrated with CNC machines. For instance, Mastercam is a popular CAM software that can generate tool paths for machining operations such as milling, turning, and drilling. By using CAM, manufacturers can achieve higher production accuracy and efficiency. A case study of a medium - sized mechanical parts manufacturer showed that after implementing CAM, the production time for complex parts was reduced by 35%, mainly due to the elimination of manual programming errors and the optimization of machining sequences.

CAE: Analyzing and Optimizing Designs

CAE software, such as ANSYS, is used for engineering analysis. It can simulate various physical phenomena like stress, strain, heat transfer, and fluid flow in a mechanical part. In the design of a high - pressure valve, CAE analysis can predict how the valve will perform under different pressure loads, temperatures, and flow rates. This helps designers optimize the part's structure, select the right materials, and ensure its reliability. According to a report by the American Society of Mechanical Engineers, products designed with CAE analysis have a 40 - 50% higher chance of meeting performance requirements on the first production run, reducing costly re - design and re - testing cycles.

Simulation and Virtual Prototyping

Simulation and virtual prototyping are revolutionary techniques that are transforming the mechanical parts design and development process.

Virtual Testing of Part Performance

Before a mechanical part is physically manufactured, simulation software can be used to test its performance in a virtual environment. For example, in the design of a gear for a transmission system, simulation software can simulate the meshing of gears, analyze the stress distribution on the teeth, and predict the wear and fatigue life of the gear. This allows designers to identify potential problems early in the design phase. A research by the Gear Manufacturers Association revealed that virtual testing of gears can reduce the number of physical prototypes needed by up to 80%, as many design flaws can be detected and corrected in the virtual world.

Cost and Time Savings

The use of simulation and virtual prototyping leads to significant cost and time savings. Creating a physical prototype of a complex mechanical part can be extremely expensive, especially when considering the cost of materials, machining, and assembly. Additionally, testing physical prototypes takes time, as each iteration of design changes requires the creation of a new prototype. With virtual prototyping, multiple design variations can be tested and optimized in a short period. A study by McKinsey estimated that companies that adopt virtual prototyping can reduce their product development time by 30 - 50% and cut development costs by 20 - 40%. For example, an aerospace company developing a new engine component was able to reduce its development time from 18 months to 10 months and save $2 million in development costs by using virtual prototyping and simulation technologies.

Yigu Technology's Perspective

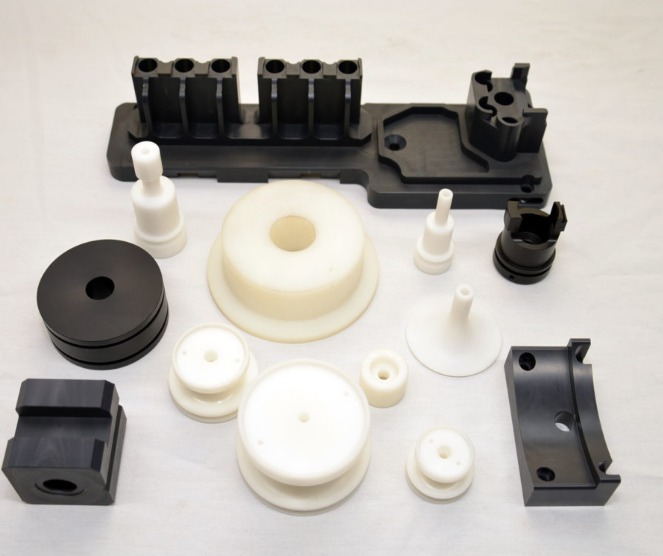

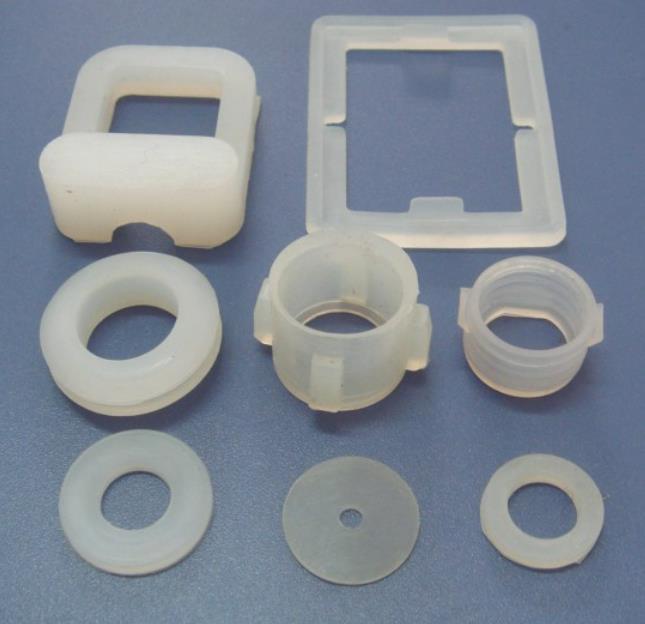

As a non - standard plastic metal custom products Supplier, Yigu Technology firmly believes that innovation in mechanical parts manufacturing is the key to staying competitive in the market. We understand that the future of this industry lies in the seamless integration of materials, processes, and design.

Material Innovation

Yigu Technology is constantly exploring new materials to meet the diverse needs of our customers. We believe that the choice of materials can significantly impact the performance, durability, and cost - effectiveness of mechanical parts. For example, we are increasingly using high - performance plastics in combination with metal inserts to create parts that are both lightweight and strong. These materials can withstand harsh environments and offer excellent corrosion resistance, making them ideal for applications in industries such as automotive, aerospace, and marine.

Process Optimization

In terms of manufacturing processes, we are committed to implementing the latest technologies to improve efficiency and precision. Our state - of - the - art CNC machines and advanced 3D printing equipment enable us to produce complex parts with tight tolerances. We also focus on reducing waste and energy consumption during the manufacturing process. By optimizing our processes, we can not only meet the high - quality requirements of our customers but also contribute to sustainable development.

Design - Driven Innovation

Design is at the heart of our innovation strategy. We have a team of experienced engineers who use the latest CAD/CAM/CAE software to design parts that are not only functional but also optimized for manufacturability. We work closely with our customers from the initial design concept to the final product, ensuring that their specific requirements are met. Our design - driven approach allows us to create unique solutions that can give our customers a competitive edge in the market.

In conclusion, Yigu Technology believes that by focusing on material innovation, process optimization, and design - driven innovation, we can continue to provide high - quality non - standard plastic metal custom products and contribute to the development of the mechanical parts manufacturing industry. We are excited about the future and look forward to collaborating with more customers to create innovative solutions.

FAQ

Q1: How do new materials impact the performance of mechanical parts?

New materials can significantly enhance the performance of mechanical parts. For example, high - strength, lightweight alloys like aluminum - lithium alloys in aerospace can reduce the weight of parts by 10 - 15% compared to traditional aluminum alloys, as Boeing's study shows. This weight reduction leads to improved fuel efficiency. High - performance plastics such as polyetheretherketone (PEEK) can withstand high temperatures up to around 343 °C and are highly resistant to chemicals. They are used in automotive engine components and medical device parts, increasing the lifespan of the parts and reducing maintenance needs.

Q2: What are the main benefits of automation in mechanical parts manufacturing?

Automation in mechanical parts manufacturing offers multiple benefits. It can increase production efficiency significantly. An automated automotive parts production line can produce thousands of parts per day, much more than a manual line. According to the International Federation of Robotics, the use of industrial robots has led to a 20 - 30% increase in productivity on average. Automation also reduces costs by minimizing human errors, which can lead to costly rework. For instance, in smartphone manufacturing, robotic assembly reduced the defect rate from 5% to less than 1%. Moreover, automated systems can operate 24/7, maximizing production output.

Q3: How does 3D printing revolutionize mechanical parts production?

3D printing revolutionizes mechanical parts production in several ways. It allows for the creation of complex - shaped parts that are difficult or impossible to manufacture with traditional methods. In aerospace, 3D - printed parts can reduce component weight by up to 40% while maintaining or improving performance. The production cycle is shortened as 3D printing can quickly turn digital models into physical parts. Wohlers Associates estimated that the global market for 3D - printed parts in manufacturing will grow at a CAGR of over 20% in the next five years. It also reduces material waste since it adds material layer by layer instead of subtracting from a larger block. Additionally, 3D printing enables customized production, meeting specific requirements for different applications.