As a complex and precise high-end equipment, the requirements for precision, strength and reliability of aircraft parts processing have reached the industry's top level. From engine blades to fuselage skin, every link is inseparable from the collaborative support of core technology, special equipment and special materials. This article will start from practical applications, dismantle the key pain points and solutions of aircraft processing, and help you fully grasp the core logic of this high-end manufacturing field.

1. Core technology and technology: cracking the "precision code" of aircraft processing

1. Five-axis linkage machining: a "one-time forming" tool for complex parts

Five-axis linkage machining is the core technology of aircraft complex structural parts processing, through the coordinated movement of three linear axes and two rotary axes of X, Y and Z to realize the multi-faceted and multi-angle clamping processing of the workpiece. Compared with traditional three-axis machining, it can greatly reduce the number of clamping times, avoid positioning errors, and control the machining accuracy within ±0.005mm.

Practical case: An aviation manufacturing company used five-axis linkage machining technology to reduce the processing process from 8 processes to 3, increasing production efficiency by 60% and reducing the scrap rate from 5% to 0.8%. This technology is especially suitable for parts with complex curved surfaces and special space structures, such as aircraft landing gear brackets, fuselage frames, etc.

2. High-speed cutting technology: "double improvement" in efficiency and quality

High-speed cutting technology is characterized by high cutting speed (usually 5-10 times that of conventional cutting) and high feed, which can effectively reduce cutting force and reduce thermal deformation. In the processing of aircraft aluminum alloy parts, the cutting speed can reach 1000-5000m/min, which is 3-5 times higher than the traditional cutting efficiency.

Technical points: This technology needs to solve the problems of fast tool wear and difficult chip discharge. By optimizing the cutting parameters (cutting speed of 3200m/min, feed rate of 0.2mm/r) and using a high-pressure cooling system, an enterprise successfully shortened the machining cycle of an aviation aluminum alloy beam from 4 hours to 1.5 hours, with a surface roughness of Ra≤0.8μm.

3. Composite processing: "technological breakthroughs" under the lightweight trend

Composite materials commonly used in aircraft (such as carbon fiber reinforced composites) have the advantages of high strength, light weight, and corrosion resistance, but they have high hardness, strong toughness, and are extremely difficult to process. Traditional machining can easily lead to defects such as material delamination, burrs, and fiber tearing.

Solution: Using laser cutting + water jet processing composite process, laser pretreatment of the material surface, water jet (pressure up to 300MPa) precise cutting, can control the processing defect rate below 1%. After using this process for the fuselage skin of a civil airliner, the weight of the parts is reduced by 25%, and the fatigue strength is increased by 30%.

4. Titanium alloy precision milling: Overcoming the challenges of "difficult metals"

Titanium alloy is widely used in key parts such as aircraft engines and landing gear due to its high strength and excellent high and low temperature resistance, but its low thermal conductivity (only 1/5 of steel) and easy to stick to knives during cutting are known as "metal stubborn stones".

Professional analysis: PCBN (polycrystalline cubic boron nitride) tools need to be selected, using low-temperature cooling (-50°C liquid nitrogen cooling) and milling strategies with small cutting depth and high feed. When a military enterprise machining titanium alloy landing gear piston rods, it extended the tool life from 20 minutes to 80 minutes by optimizing the tool angle (rake angle 5°, trailing angle 12°) and cutting parameters, and the machining accuracy reached H7 level.

5. Adaptive machining technology: "real-time adjustment capability" for the machine

Adaptive machining technology monitors cutting force, temperature, vibration and other data in real time through sensors, and the system automatically adjusts the cutting parameters (rotation speed, feed, cutting depth) to make up for errors caused by uneven material allowance and tool wear.

Application value: In the mass production of aircraft structural parts, this technology can control the fluctuation of processing size within ±0.01mm, which is 15%-20% higher than the traditional processing pass rate. When processing wing girders, an aviation factory corrects the elastic deformation of materials in real time through an adaptive system, improving the assembly accuracy of parts by 25%.

6. Ultra-precise surface treatment: Giving parts "ultimate performance"

Ultra-precision surface treatment is the last critical process in aircraft parts processing, which requires controlling the surface roughness to Ra≤0.02μm while ensuring surface hardness, wear resistance, and corrosion resistance.

Comparison of common methods:

| Treatment method | Applicable scenarios | Surface roughness | Hardness increased |

| Ion beam processing | Engine blades | Ra≤0.01μm | 30%-40% |

| Magnetorheological polishing | Optical components | Ra≤0.005μm | 15%-20% |

| Chemical-mechanical grinding | fuselage structural parts | Ra≤0.02μm | 20%-25% |

2. Equipment and tools: "hard-core support" for aircraft processing

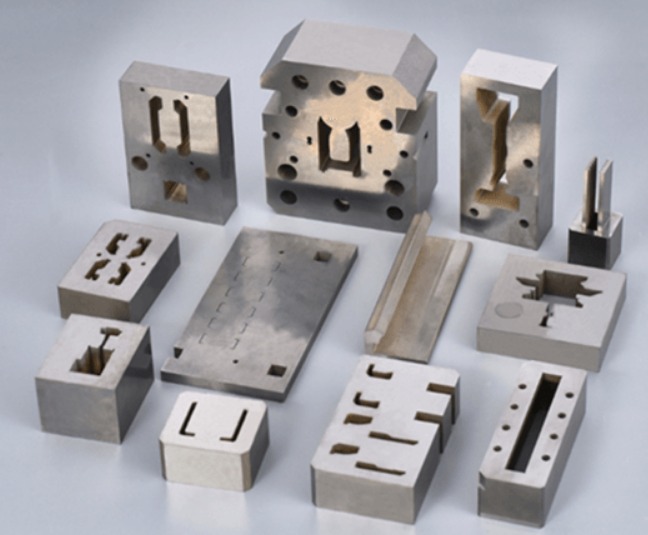

1. CNC machine tools for aviation: the "core carrier" of high-precision machining

The aviation CNC machine tool has the characteristics of high rigidity, high precision, and high stability, with a positioning accuracy of up to ±0.001mm and a repeat positioning accuracy of ±0.0005mm. Its multi-axis linkage capability (up to 9 axes) meets the machining needs of complex parts.

Key parameters: The spindle speed of a brand of aviation special machine tool can reach 20000rpm, the rapid traverse speed is 60m/min, and it is equipped with a grating ruler closed-loop feedback system, which can compensate for positioning errors in real time, and is suitable for the processing of engine blades, precision gears and other parts.

2. Highly rigid machining centers: "Solid backing" for large cutting forces

The machining of large structural parts of aircraft (such as wing beams and fuselage frames) needs to withstand huge cutting forces, and the highly rigid machining center ensures that there is no vibration deformation during the machining process by optimizing the bed structure (using cast iron + granite composite bed) and enhancing the rigidity of the spindle (spindle diameter ≥ 100mm).

Actual case: A heavy aviation machining center has a bed weight of 50 tons, a spindle rigidity of 200N/μm, and when processing aviation aluminum alloy structural parts weighing 3 tons, the machining accuracy fluctuates ≤ 0.008mm, which fully meets the strict requirements of aircraft structural parts.

3. Specialized cutting tools: the "sharp edge" of aircraft machining

Aircraft processing tools need to be adapted to different materials (titanium alloys, composite materials, superalloys), common ones include PCBN tools, diamond-coated tools, carbide tools, etc.

Selection principle: PCBN tools are preferred for machining titanium alloys (high temperature resistance up to 1200°C); diamond-coated tools (hardness HV≥8000) are used for processing composite materials; Ceramic tools are used for machining superalloys (wear resistance is 5 times higher than that of cemented carbide). A tool company has developed a special ball head milling cutter for aero engine blade processing, which has a lifespan of 3 times that of traditional tools, and the processing efficiency has been increased by 40%.

4. On-machine measurement system: "smart eye" that controls accuracy in real time

The in-machine measurement system is integrated into the processing equipment, through the contact probe or laser sensor, the size and shape of the workpiece are measured in real time, and the processing parameters are automatically corrected after the data is fed back to the control system to avoid the secondary clamping error caused by offline measurement.

Technical advantages: The measurement accuracy of an on-board measurement system reaches ±0.002mm, and the measurement efficiency is 50% higher than that of traditional coordinate measuring machines, and the dimensional out-of-error rate can be reduced from 3% to 0.5% in the processing of aircraft landing gear parts.

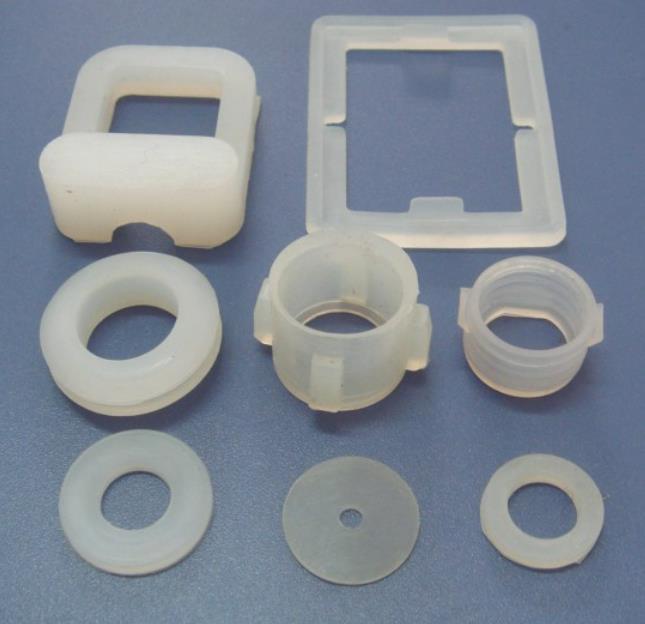

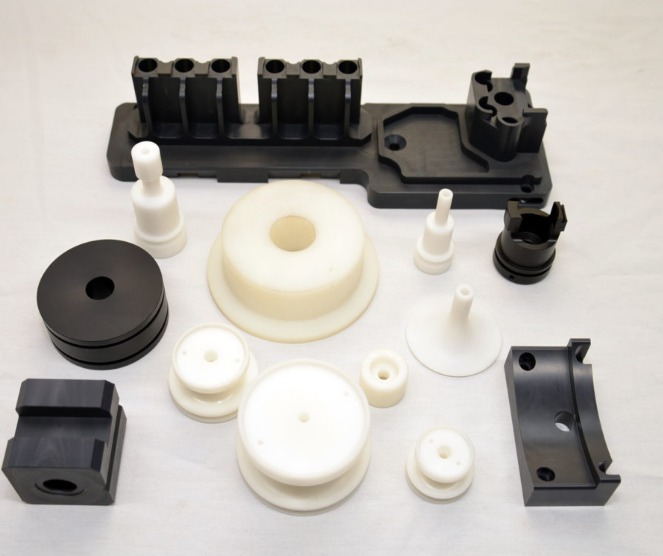

5. Aviation tooling fixtures: the "key guarantee" for precise positioning

Aviation tooling fixtures need to meet the requirements of high-precision positioning (positioning error ≤0.005mm), fast clamping, and high repeatable positioning accuracy. Common types include modular clamps, vacuum clamps, hydraulic clamps, etc.

Application scenarios: When processing the skin of the fuselage, use vacuum adsorption fixtures (adsorption force ≥0.08MPa) to avoid damage to the skin surface caused by the fixtures; When processing engine blades, use hydraulic grippers (repeat positioning accuracy ±0.003mm) to ensure that the blade processing standards are consistent.

6. Intelligent Tool Management System: The "Digital Butler" for Efficiency

The intelligent tool management system records tool information (model, life, wear status) through RFID technology to realize automatic tool scheduling, life prediction and fault alarm.

Data support: An aviation factory has seen a 30% reduction in tool utilization from 75% to 92%, a 30% reduction in tool loss costs, and an 18% increase in production plan completion.

3. Materials and components: the "core cornerstone" of aircraft manufacturing

1. Processing of aerospace structural parts: balancing strength and lightweight

Aviation structural parts (such as wing girders and fuselage frames) need to meet the requirements of high strength, lightweight, and fatigue resistance, and the commonly used materials are aviation aluminum alloy, titanium alloy, and composite materials.

Machining points: Adopting the three-stage process of "roughing - semi-finishing - finishing", roughing removes more than 80% of the margin (cutting speed 500-800m/min), semi-finishing corrects the shape (accuracy ±0.05mm), and finishing ensures surface quality (Ra≤0.8μm). When a company processes carbon fiber-reinforced composite structural parts, it optimizes the milling path to increase the strength of the machined structural parts by 15% and reduce the weight by 20%.

2. Engine Blade Manufacturing: The precision of the "heart" of the aircraft

Engine blades are the core of the aircraft power system, with an operating temperature of more than 1500°C, and need to withstand the rigors of high temperature, high pressure and high-speed rotation.

Manufacturing process: Using the "casting - forging - CNC machining - surface treatment" process, casting ensures the blade blank forming (dimensional tolerance ±0.1mm), forging improves material strength (tensile strength ≥1200MPa), CNC machining ensures profile accuracy (profile error ≤ 0.03mm), and surface treatment enhances wear resistance (hardness ≥HRC55). An aero engine blade is made of monocrystalline alloy and has a service life of 8,000 flight hours, which is 50% higher than conventional blades.

3. Landing gear component machining: "critical components" for carrying safety

Landing gear parts (such as piston rods, shock absorbing struts) need to have high strength, high toughness and corrosion resistance, and the commonly used materials are 300M steel and titanium alloy.

Machining difficulties and solutions: 300M steel has high hardness (HRC30-35) and severe work hardening, requiring the use of carbide tools + high-pressure cooling (pressure 20MPa), and the cutting speed is controlled at 100-150m/min. Titanium alloy parts are prone to cracks at the weld, and electron beam welding technology (welding deformation ≤ 0.02mm) is used to ensure that the welding strength meets the standard.

4. Aerospace aluminum alloy processing: the "main material" of lightweight

Aviation aluminum alloys (such as 7075, 2024 aluminum alloys) have a density of only 1/3 of steel and a strength of up to 80% of ordinary steel, making them widely used in fuselage skins, wings, tails, and other components.

Machining precautions: Aluminum alloy is easy to stick and easy to produce edges, so it is necessary to choose a sharp tool (rake angle 15°-20°), high cutting speed (1000-3000m/min) and large feed rate (0.2-0.5mm/r), with emulsion cooling (cooling pressure 5MPa). When processing the skin of the 7075 aluminum alloy body, the surface roughness reached Ra≤0.4μm through the above process, and the processing efficiency was increased by 3 times.

5. Superalloy Components: The "Steel Warrior" Resistant to Extreme Environments

Superalloys (such as Inconel 718, GH4169) maintain high strength and stability in 600-1200°C environments and are the core materials for high-temperature components such as engine combustion chambers and turbine blades.

Machining challenges and breakthroughs: Superalloys have low thermal conductivity, high cutting force, and fast tool wear. An enterprise uses ceramic tools + ultrasonic assisted machining technology, which reduces the cutting force by 30%, extends the tool life by 2 times, and the performance of the processed superalloy parts is reduced by 5% after working ≤for 1000 hours in a 1000°C environment.

6. Fuselage Skin Forming Technology: Shaping Smooth "Aircraft Coat"

The fuselage skin needs to have good aerodynamic shape and structural strength, and commonly used forming technologies include stretch forming, shot peening, creep aging forming, etc.

Technical comparison:

| Forming technology | Applicable materials: | Forming accuracy | Production efficiency |

| Stretch molding | Aviation aluminum alloy | ±0.5mm | high |

| Shot peening | Composite materials, titanium alloys | ±0.3mm | middle |

| Creep aging takes shape | High-strength aluminum alloy | ±0.2mm | low |

Application case: The fuselage skin of a large passenger aircraft adopts the composite process of "stretch forming + shot peening", and the size error of the skin after forming is ≤0.3mm, and the fatigue life is increased by 40%, which fully meets the requirements of aerodynamic shape and structural strength.

4. Yigu Technology's view

Aircraft processing is the "pearl" of high-end manufacturing, and its core competitiveness lies in the deep synergy of technology, equipment and materials. At present, intelligence, lightweight and high precision have become the development trend of the industry, and the application of adaptive machining, intelligent tool management and other technologies is breaking the bottleneck of traditional machining. As an enterprise deeply involved in the field of high-end manufacturing, Yigu Technology believes that future aircraft processing needs to focus on two major directions: one is to achieve full-process quality traceability through digital technology, and the other is to develop more efficient composite processing technology and special materials. Only by continuously breaking through technical barriers can we meet the core needs of the aviation industry for higher precision, higher efficiency and lower cost.

5. FAQ

- Q: What are the core advantages of five-axis linkage machining compared with three-axis machining?

A: The core advantage is that it completes multi-sided processing in one clamping, reduces positioning errors, improves machining accuracy by more than 30%, and increases production efficiency by 50%-80%, especially suitable for complex curved parts.

- Q: How to solve the problem of sticking knives when machining titanium alloys?

A: PCBN or diamond-coated tools are optional, using low-temperature cooling (liquid nitrogen or low-temperature emulsion), controlling the cutting speed at 100-200m/min, increasing the rake angle of the tool (5°-10°), and avoiding chip accumulation.

- Q: What are the main differences between aviation CNC machines and ordinary CNC machines?

A: The aviation CNC machine tool has higher rigidity, accuracy and stability, positioning accuracy up to ±0.001mm, supports multi-axis linkage (up to 9 axes), can adapt to aviation special material processing, and is equipped with on-machine measurement, intelligent compensation and other functions.

- Q: How to avoid delamination and fiber tearing in composite processing?

A: Laser pretreatment + water jet cutting compound process is used to control the cutting speed (10-30mm/min) and water pressure (200-300MPa), and diamond-coated tools are selected to reduce cutting force and avoid material damage.

- Q: What is the core role of ultra-precision surface treatment in aircraft parts?

A: Reduce surface roughness (Ra≤0.02μm), improve wear resistance, corrosion resistance, and fatigue resistance, extend the service life of components, and ensure the reliability of aircraft in extreme environments.