Introduction: Why is choosing the right machining tool so crucial?

In the world of machining, knives are like "craftsmen's hands" – they directly determine the precision of the workpiece, production efficiency, and manufacturing costs. Whether it's mass production of automotive parts or custom machining of precision molds, choosing the right tool type can often increase machining efficiency by more than 30% and extend tool life by 50%. But in the face of a variety of tool types, from traditional turning tools to intelligent CNC tools, many engineers will be confused: which tool to choose in different scenarios? What are their core differences? This article will comprehensively dismantle the "multiverse" of machining tools from infrastructure to practical application to help you accurately match your needs.

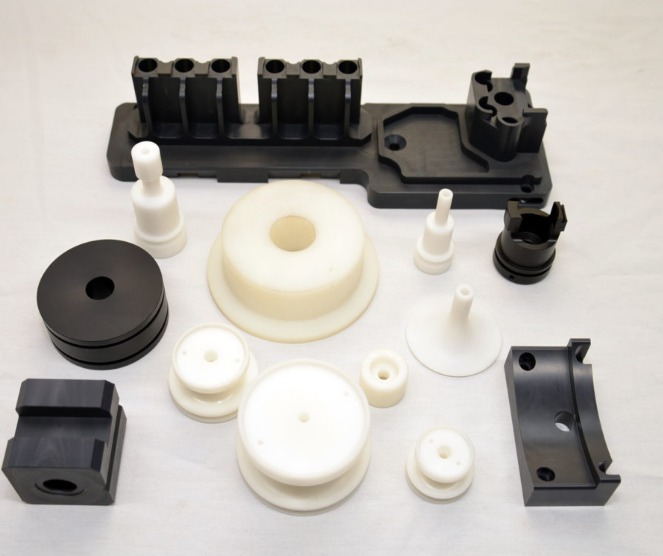

1. The core password of the tool: structure and material classification

The essential differences in machining tools stem first from the core structure and the material of manufacture – the "genes" that determine their cutting performance.

1. Structure type: one-piece vs indexable

- Integral tools: The tool and tool holder are integrated into the molding, commonly found in drills, end mills, etc. The advantage is strong rigidity and high precision, suitable for high-precision machining of small and medium-sized workpieces. For example, in the machining of mobile phone middle frames, solid carbide end mills can achieve a profile accuracy of 0.01mm.

- Indexable tool: consists of a tool holder and a replaceable blade, the blade is fixed by screws, according to ISO 1832 standards. The core advantage is economy, when the blade wears out, there is no need to replace the entire tool, only the blade needs to be replaced. An auto parts factory reduced tool costs by 40% after using indexable turning tools.

- Supplement: The choice of tool holder is also crucial, and common HSK, CAT, BT tool holders will be detailed in the subsequent "CNC Tool System".

2. Tool Materials: "Performance Adaptation" for Different Scenarios

| Material type | Hardness (HRC) | Heat resistance temperature (°C) | Core application scenarios | Typical case |

| High-speed steel | 62-65 | 550-600 | General machining, low-speed cutting | Handmade taps, drills |

| Carbide | 89-93 | 800-1000 | High-speed cutting, difficult-to-machine materials (stainless steel) | CNC turning tool inserts, end mills |

| Ceramics | 94-96 | 1200-1400 | Ultra-high-speed cutting, high-temperature alloy processing | Aero engine blade grinding tools |

| Cubic Boron Nitride (CBN) | 97-98 | 1300-1500 | Hard material processing (HRC55 and above) | Gears are hardened and then finished |

| diamond | 99 | 700-800 | processing of non-ferrous metals and non-metallic materials | Aluminum profile high-gloss cutting tools |

3. Surface Coating and Geometry: A "plus" for improved performance

- Surface Coating: Common titanium nitride (TiN) coatings can improve tool wear resistance, diamond-like carbon (DLC) coatings reduce cutting resistance, and alumina (Al₂O₃) coatings enhance high-temperature resistance. For example, TiN-coated taps have 2-3 times longer tap life than uncoated products.

- Geometric angle: rake angle affects the cutting force (the larger the rake angle, the faster the cut, but the rigidity is reduced), the rake angle reduces the friction between the tool and the workpiece, and the edge radius determines the surface finish. When processing soft materials (such as aluminum), a large rake angle (15°-20°) is recommended; When machining hard steel, choose a small rake angle (5°-10°).

2. The "sharp edge" of traditional cutting: the conventional tool family

Traditional cutting tools remove material through the shear deformation of sharp edges, which can be divided into three categories according to the number of cutting edges and processing technology:

1. Single-edged cutters: the precise and efficient "lone ranger"

- Turning tools: used in turning processing, can process outer circles, end faces, and threads. For example, when machining shaft parts, carbide turning tools can achieve high-speed cutting of 500m/min.

- Boring tools: Focusing on internal hole machining, divided into rough boring tools and fine boring tools. A mold factory uses a fine boring tool to process the mold cavity, and the internal hole accuracy reaches IT7 level.

- Planing cutter: used for planing processing, suitable for low-speed machining of flat surfaces and grooves, commonly used in ordinary machine tools.

2. Multi-edge Tools: The "King of Efficiency" for Mass Production

- End mills: including flat bottom milling cutters (machining flat surfaces), ball nose milling cutters (machining curved surfaces), and round nose milling cutters (taking into account both flat and curved surfaces), are the core tools of CNC milling machines. For example, when machining curved surfaces of mobile phone shells, ball nose milling cutters can guarantee a surface roughness of Ra≤0.8 μm.

- Face milling cutter: Used for large-area flat surface machining, with a large number of cutting edges (4-12 flutes), high machining efficiency. When a machine tool factory processes a worktable, the material removal rate of the face mill reaches 100cm³/min.

- Drill tools for hole machining: drill (drilling), reamer (reaming, accuracy IT6-IT8), tap (tapping thread). For example, the machining of M10 threads is drilled first and then tapped, and carbide taps can process more than 5,000 holes.

- Broach: Used for high-precision machining of inner holes and keyways, which can be completed with one feed, suitable for mass production.

3. Grinding tools: the "last step" for improved precision

- Grinding wheel: divided into alumina grinding wheel (processing steel parts) and silicon carbide grinding wheel (processing cast iron), used for grinding processing, the accuracy can reach IT5 level.

- Honing tools: Used for internal hole finishing, with a surface roughness of Ra≤0.2μm.

- Grinding tools: Manual or semi-automatic grinding for the final machining of ultra-precision parts.

3. Intelligent pioneers: CNC and advanced manufacturing tools

With the transformation of the manufacturing industry to automation and intelligence, CNC and advanced manufacturing tools have become the core support, emphasizing automation, compounding, and intelligence.

1. CNC machines: the "intelligent carrier" of tools

- CNC lathe, CNC milling machine: basic CNC equipment, with CNC tools to achieve high-precision machining.

- Machining center, turning center: Integrated automatic tool change function, can realize multi-process compound machining. For example, when machining complex parts, the machining center can automatically complete milling, drilling, boring and other processes, reducing the number of clamping times.

- Data support: The tool utilization rate of the machining center is 60% higher than that of ordinary machine tools, and the production efficiency is increased by more than 40%.

2. Tool systems: the "core link" of automation

- Automatic Tool Changer (ATC) + Tool Magazine: The tool magazine can store 16-60 tools, and the ATC tool change time is only 1-3 seconds, enabling unmanned machining.

- Tool holder system: HSK tool holder (high-speed machining, speed up to 30000rpm), CAT tool holder (European and American standard), BT tool holder (Japanese standard), which need to be selected according to the machine tool interface. For example, when milling dies at high speeds, the HSK tool holder has significant advantages in rigidity and precision.

3. Advanced machine tools and manufacturing systems

- Parallel (hexapod) machine tool: suitable for complex curved surface processing, highly flexible, often used in aerospace parts production.

- Reconfigurable machine tools: The structure can be adjusted according to the processing needs and adapted to the production of multiple varieties and small batches.

- Industrial Robot + Flexible Manufacturing System (FMS): Robots are responsible for loading and unloading, FMS realizes multi-machine tool collaboration, and tools are optimized for use through intelligent scheduling systems. An FMS production line in an automobile factory has a tool life management accuracy of ±5%.

4. Stable cornerstone: tooling and fixture system

The tooling fixture is the "guarantee line" of machining accuracy, and its core role is to position the workpiece, clamp firmly, and avoid displacement or deformation during processing.

1. Core principle: 3-2-1 positioning principle

That is, 3 points limit the movement of the X, Y, Z axes, 2 points limit rotation, and 1 point limit the last degree of freedom, ensuring that the workpiece is uniquely positioned in the machining. This is the basic principle of all fixture design.

2. Fixture classification: general vs. specialized

| Fixture type | Features: | Applicable scenarios | Case |

| Universal fixtures | Highly versatile, no customization required | Small batch production of single pieces | Vise (clamping plate), chuck (clamping shaft) |

| Special fixtures | Customized design and precise positioning | Mass production | Special clamp for automobile engine block |

| Advanced fixtures | Modular, automated | Flexible production and high-precision processing | Vacuum suction cups (thin-walled parts), hydraulic clamps (heavy duty parts) |

3. Choose key factors

- Workpiece deformation: Vacuum suction cups or elastic fixtures should be selected for thin-walled parts to avoid deformation caused by excessive clamping force. For example, when processing aluminum alloy thin-walled sleeves, the deformation of the vacuum suction cup ≤ 0.02mm.

- Tool Accessibility: The fixture cannot obstruct the machining area, ensuring that the tool can reach all machining surfaces smoothly.

5. Practical guide: scientific selection and application of knives

The core of choosing the right tool is "matching demand", which needs to comprehensively consider factors such as workpiece material, processing technology, and precision requirements, and the following are practical suggestions:

1. Selection basis: 6 core dimensions

- Workpiece material: soft materials (aluminum, copper) choose tools with large rake angle and sharp cutting edge; For hard materials (steel, cast iron), choose carbide or CBN tools.

- Machining accuracy: high rigidity and large feed tools for rough machining; Finishing selects high-precision, sharp cutting edge tools.

- Production batch: select the overall tool in small batches (low cost); Large batches of indexable tools (easy to replace).

- Machine tool capacity: ordinary machine tools are selected for general tools; The machining center selects high-precision, quick-changing tools.

- Design complexity: curved surface processing ball head milling cutter; Drill bit + reamer combination for hole processing.

- Surface finish: When the requirements are high, choose small feed and sharp edge tools, with appropriate coatings.

2. Performance indicators: interpretation of key parameters

- Material removal rate: The larger the volume of material removed per unit time, the higher the efficiency (roughing is preferred).

- Cutting speed, feed: It is necessary to match the tool material and workpiece material, such as when processing steel parts with carbide, the cutting speed can reach 200-300m/min.

- Tool life: Usually measured by the number of machined parts or cutting time, a reasonable setting of life can avoid scrap caused by tool failure.

3. Machining strategy: the process adapts to the tool

- Rough machining: Give priority to removing the allowance, and choose high-rigidity, large-feed tools (such as rotatable surface milling cutters).

- Semi-finishing: Correct the shape and select tools with medium accuracy and sharp edges.

- Finishing: To ensure accuracy and surface quality, select high-precision, small-feed tools (such as fine boring tools, ball head milling cutters).

- High-speed milling: Choose HSK tool holders, carbide or ceramic tools with a rotation speed ≥ 10000rpm, suitable for mold processing.

6. Yigu Technology's views

As an enterprise focusing on advanced manufacturing technology, Yigu Technology believes that the development of machining tools is evolving in three major directions: material upgrading, structural optimization, and intelligent interconnection. In the future, tools will no longer be isolated machining tools, but "data nodes" integrated into intelligent manufacturing systems - real-time monitoring of cutting force, temperature and other parameters through sensors, combined with AI algorithms to optimize tool life and machining parameters. For enterprises, the selection of tools should not only focus on a single performance, but also build a collaborative system of "tool-machine-fixture-process" to maximize production efficiency. At the same time, under the trend of green manufacturing, efficient, long-lasting, and environmentally friendly tool materials (such as new cemented carbide and ceramic composite materials) will become the mainstream of the market.

7. FAQ

- Q: Which tool material is most suitable for machining stainless steel?

A: Stainless steel has high toughness and is easy to stick, and it is recommended to use carbide (TiAlN coating optional) or cubic boron nitride (CBN) tools, with a large rake angle and sharp edge design to reduce cutting resistance.

- Q: What is the cost difference between indexable tools and overall tools?

A: Initial purchase cost: indexable tools are 30%-50% higher than integral tools; However, with long-term use (machining more than 1000 pieces), the comprehensive cost of indexable tools (including replacement inserts) is 40%-60% lower than that of the overall tool.

- Q: How to choose a tool holder for CNC machining center?

A: For high-speed machining (rotation speed ≥ 15000rpm), choose HSK tool holder (good rigidity, high concentricity); BT or CAT tool holders are available for general machining, which need to be matched to the machine spindle interface (BT40, BT50, etc.).

- Q: How to avoid workpiece deformation and tool collision when machining thin-walled parts?

A: Choose vacuum suction cup or flexible fixture for the fixture to reduce the clamping force; Tool selection of small diameter and multi-flute end mills, adopting the machining strategy of small feed and high speed; At the same time, the clamp structure is optimized to ensure tool accessibility.

- Q: What is the general lifespan of tool coatings?

A: The lifespan of different coatings varies greatly: TiN coatings have a lifespan of about 500-1000 pieces; DLC coatings have a lifespan of about 800-1500 pieces; TiAlN coatings have a lifespan of about 1000-2000 pieces, depending on the processing material and cutting parameters.