When your project demands high-precision components, finding the right manufacturing partner is critical. Machining Services Inc. is a term you'll often encounter in this search. But what truly defines such a company, and how can its capabilities translate into tangible success for your product? This article goes beyond the company name to explore the core offerings, technological backbone, and collaborative expertise that a top-tier machining service provider delivers. We'll break down what you should expect, from foundational capabilities and industry-specific applications to advanced technologies and material mastery, helping you understand how a professional machining partner can become an integral extension of your engineering team.

What Core Machining Capabilities Does the Company Provide?

A reputable machining services provider acts as a one-stop hub for transforming raw materials into finished, functional parts. Their core competencies typically span several essential processes.

CNC Milling and Turning

These are the foundational pillars. Computer Numerical Control (CNC) machining offers unparalleled repeatability and complexity. CNC milling uses rotary cutting tools to shape stationary workpieces, ideal for creating pockets, slots, and complex 3D contours. CNC turning, on the other hand, rotates the workpiece against a stationary tool, perfect for producing cylindrical parts like shafts, bolts, and fittings. Modern multi-axis CNC centers combine these operations, allowing a part to be completed in a single setup, which dramatically improves accuracy and reduces lead times.

Precision Grinding and Finishing

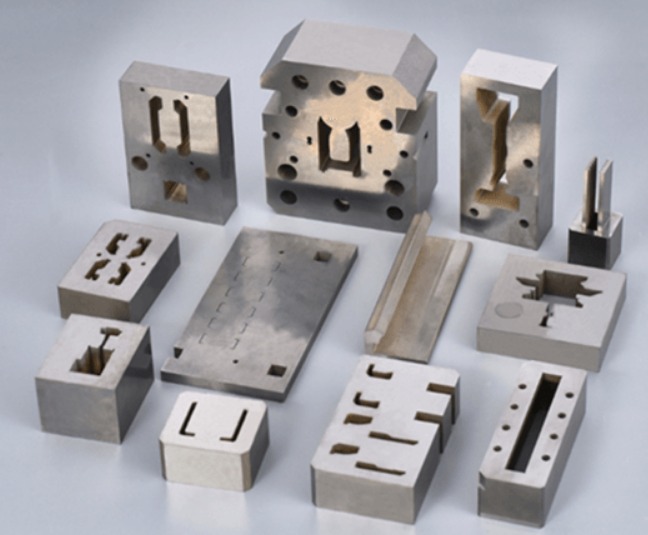

When tolerances become extremely tight—think within microns—precision grinding services are essential. This process uses an abrasive wheel to achieve superior surface finishes and exacting dimensional accuracy on hardened metals. It’s crucial for components like injection molds, aerospace bearings, and medical implant surfaces. Complementary finishing processes, including deburring, polishing, and various surface treatments (like anodizing or plating), ensure the final part meets not only dimensional specs but also aesthetic and functional requirements for corrosion resistance or wear properties.

Which Industries Rely on Professional Machining Services?

The demand for precision spans virtually every sector that involves physical products. A versatile machining services provider must understand the unique regulatory, material, and performance requirements of each.

- Aerospace & Defense: This sector demands absolute reliability. Parts must withstand extreme stresses, temperatures, and environments. Machining for aerospace involves exotic alloys like Inconel and titanium, adhering to strict certifications like AS9100, and producing complex structural components, engine parts, and landing gear assemblies with flawless traceability.

- Medical & Life Sciences: Here, precision is directly linked to patient safety. Medical device machining requires biocompatible materials (e.g., stainless steel 316L, titanium, PEEK), exceptionally smooth surfaces to prevent bacterial adhesion, and validation for cleanroom production. Examples include surgical instruments, orthopedic implants, and components for diagnostic equipment.

- Automotive & Transportation: From prototyping to high-volume production, this industry leverages machining for both innovation and efficiency. Applications range from precision engine blocks and transmission components to custom parts for electric vehicle battery packs and advanced sensor housings, often requiring robust supply chain management.

- Industrial Machinery & Robotics: This broad sector needs durable, reliable components that ensure uptime. Custom machining produces gears, hydraulics, actuator bodies, and robotic end-effectors that operate with high precision in demanding factory environments, often from tough tool steels or aluminum.

What Advanced Equipment and Technologies Are Employed?

Staying competitive means investing in state-of-the-art technology. Leading shops utilize equipment that pushes the boundaries of what's possible.

Multi-Axis CNC Machining Centers

The move from 3-axis to 5-axis CNC machining is a game-changer. It allows the cutting tool to approach the workpiece from nearly any direction in a single operation. This eliminates multiple setups, reduces errors, and enables the machining of incredibly complex geometries—such as turbine blades, impellers, and monolithic aerospace structures—that are impossible with simpler machines. This capability directly translates to faster production times and higher design freedom for engineers.

Automation and Smart Manufacturing

To ensure consistency and scale production, advanced providers integrate automation. This includes:

- Robotic Part Loading/Unloading: For lights-out production runs.

- Pallet Systems: Allowing one setup to be prepared while another is running.

- Real-Time Monitoring (IoT): Sensors track tool wear, vibration, and temperature, predicting maintenance needs and preventing defects before they occur.

Complementary Technologies

A full-service provider often complements CNC machining with other technologies to offer a complete solution.

| Technology | Key Benefit | Common Application with Machining |

|---|---|---|

| Coordinate Measuring Machine (CMM) | Verifies part dimensions with micron-level accuracy for quality assurance. | First-article inspection and statistical process control. |

| Wire Electrical Discharge Machining (EDM) | Cuts intricate shapes and hard materials using electrical sparks. | Creating precision molds, fine gears, and features in hardened steel. |

| Additive Manufacturing (3D Printing) | Builds complex prototypes or hybrid parts layer-by-layer. | Rapid prototyping for validation, creating conformal cooling channels in tooling. |

Material Expertise and Processing Options

The best design is only as good as the material it's made from. An expert machining services partner provides guidance on material selection and processing.

Metals: This includes everything from common aluminum and steel alloys to challenging stainless steels, titanium, and high-temperature superalloys like Inconel. Each has unique machining characteristics—for instance, aluminum machines quickly but requires sharp tools to avoid built-up edge, while titanium is strong but has poor thermal conductivity, demanding specific speeds and coolants.

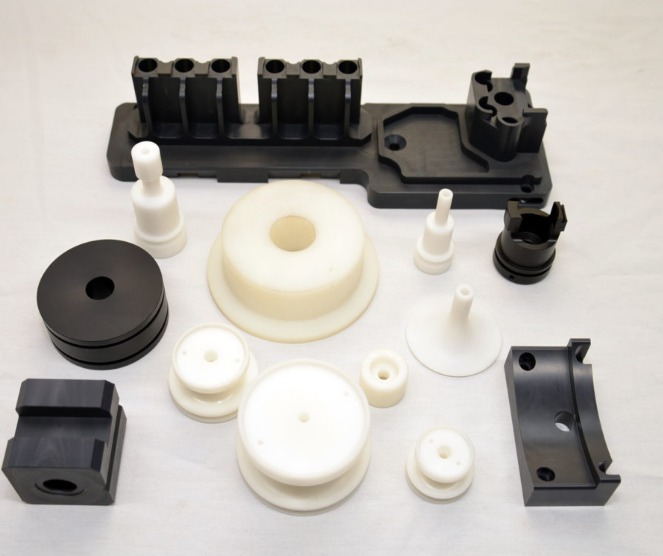

Plastics & Composites: For applications requiring lightweight, corrosion resistance, or electrical insulation. Machining plastics like PEEK, UHMW, and Delrin requires different strategies to manage heat and prevent deformation.

Material Properties Guide for Common Choices:

- Aluminum 6061-T6: Excellent strength-to-weight, good machinability. Ideal for: Aerospace frames, automotive parts, consumer electronics.

- Stainless Steel 304/316: High corrosion resistance, durable. Ideal for: Medical devices, food processing equipment, marine components.

- Titanium (Grade 5/Ti-6Al-4V): Exceptional strength, lightweight, biocompatible. Ideal for: Aerospace structural parts, medical implants, high-performance automotive.

- PEEK (Polyetheretherketone): High-performance thermoplastic, chemical and heat resistant. Ideal for: Semiconductor components, medical sterilization trays, aerospace interiors.

Custom Machining Solutions and Engineering Support

The true differentiator of a top Machining Services Inc. is its ability to collaborate. It's not just about making a print; it's about making the part work optimally and cost-effectively.

Design for Manufacturability (DFM) Analysis

This is where engineering support adds immense value. Upon receiving a design, experienced engineers perform a DFM review. They might suggest subtle changes—like adjusting a corner radius to allow for a standard tool size, adding a slight draft to ease part ejection, or modifying a tolerance that is unnecessarily tight—that can significantly reduce machining time and cost without compromising function.

From Prototype to Full Production

A strong partner guides you through the entire product lifecycle.

- Rapid Prototyping: Using quick-turn CNC machining or 3D printing to get functional parts in hand for testing and design iteration.

- Low-Volume Production: Perfect for bridge tooling, pilot runs, or products that don't justify expensive injection molds.

- High-Volume & Sustained Production: Leveraging automated cell production and stringent quality control systems for efficient, long-term supply.

A Case in Point:

An automotive startup designed a complex sensor housing with deep, thin-walled pockets. Their initial quotes were high, and lead times were long. By partnering with a machining services provider for DFM, they redesigned the part to be manufactured as two simpler components that could be efficiently machined and then joined. This design optimization reduced the machining cost by 35%, improved structural integrity, and cut the lead time in half, accelerating their path to market.

Conclusion

Choosing a machining services provider is a strategic decision that impacts your product's quality, cost, and time-to-market. It involves more than just selecting a shop with machines; it's about partnering with a team that brings core machining expertise, industry-specific knowledge, advanced technological capabilities, deep material science understanding, and proactive engineering support to the table. By looking for a partner that excels in these areas, you secure not just a vendor, but a collaborative extension of your own capabilities, ensuring your most challenging designs are realized with precision and reliability.

FAQ

What file formats do I need to provide for a machining quote?

Most machining services providers require a 3D CAD model (e.g., STEP, IGES, SLDPRT) along with a 2D drawing (PDF or DWG) that specifies critical dimensions, tolerances, material, and finish requirements.

What is the typical lead time for machined parts?

Lead time depends on part complexity, quantity, and material availability. Simple prototypes can often be shipped in 3-5 days, while complex, low-volume production runs may take 2-4 weeks. Always discuss timeline requirements upfront.

How do you ensure the quality of machined parts?

Quality is assured through a multi-step process: First-Article Inspection using tools like CMMs, in-process checks by machinists, and final inspection against your drawings. Reputable providers are often certified to standards like ISO 9001 or AS9100, which mandate documented quality systems.

Can you work with both metric and imperial units?

Yes, professional precision machining shops are equipped and experienced in working with both metric (mm) and imperial (inches) measurement systems. Clearly specify your preferred unit on all drawings.

What are the minimum and maximum part sizes you can machine?

This varies by shop capacity. Typically, shops can handle parts from tiny components under 1 mm in size to large fabrications measuring several feet. It's best to inquire about a specific provider's machine envelope capabilities.

Contact Yigu for Custom Manufacturing.

Ready to bring your precision components to life? At Yigu, we combine state-of-the-art CNC machining services with deep engineering expertise to deliver unparalleled quality and reliability. From your initial prototype to full-scale production, our team is dedicated to providing custom machining solutions that meet your exact specifications, timeline, and budget.

Submit your CAD files today for a fast, detailed quote and expert DFM feedback. Let's build something exceptional together.