In the competitive world of manufacturing, speed is synonymous with efficiency, cost-effectiveness, and market agility. Fast machining, or High-Speed Machining (HSM), stands at the forefront of this pursuit. But it's far more than just running a spindle faster. It represents a sophisticated, system-wide approach to material removal that fundamentally changes production dynamics. This article delves into the core principles, enabling technologies, and practical applications of fast machining. We'll move beyond basic definitions to explore how it differs from traditional methods, which materials and strategies unlock its true potential, and the tangible benefits it delivers to modern manufacturing.

What Defines Fast Machining?

Fast machining is not merely defined by a single high spindle speed. It is a comprehensive machining strategy characterized by exceptionally high spindle speeds, significantly increased feed rates, and very light depths of cut. The core objective is to achieve a much higher material removal rate (MRR) while simultaneously improving surface finish, reducing machining forces, and dissipating heat more effectively through the ejected chips, not the workpiece.

True HSM operates within specific parameters that often push machines beyond 10,000 RPM, with feed rates potentially exceeding 1,000 inches per minute (IPM), depending on the material and tooling. The science behind it hinges on a critical relationship: as cutting speed increases, the heat generated during the cut is carried away by the chip before it can transfer into the workpiece or tool, leading to better part integrity and longer tool life under optimal conditions.

How Does It Differ from Traditional Methods?

The difference is paradigm-shifting. Traditional machining relies on heavier cuts at lower speeds and feeds. This often induces significant vibration, heat buildup in the part, and higher mechanical stresses.

| Feature | Traditional Machining | Fast Machining (HSM) |

|---|---|---|

| Primary Strategy | Deep cuts, low speed/feed | Light cuts, very high speed/feed |

| Heat Management | Heat sinks into workpiece/tool | Heat evacuates with the chip |

| Cutting Forces | Higher radial forces | Lower radial forces, reduced vibration |

| Typical Application | Roughing, heavy stock removal | Finishing, complex contours, hard materials |

| Surface Finish | Often requires secondary finishing | Can achieve excellent finish directly |

In practice, a traditional method might use a 1/2-inch end mill taking a 0.150-inch depth of cut at 100 IPM. A fast machining approach for the same final result might use a 1/4-inch end mill taking a 0.020-inch depth of cut at 800 IPM, drastically reducing load on the tool and machine while maintaining or even increasing overall throughput for finishing operations.

What Technologies Enable High-Speed Cutting?

Achieving reliable fast machining requires a synergistic integration of advanced technologies:

- Machine Tool Design: The foundation is a highly rigid, dampened machine structure (often polymer-concrete or heavily ribbed cast iron) to absorb vibrations. It requires high-speed spindles (20,000-60,000 RPM is common for HSM) with precise cooling and lubrication systems, and ultra-fast, high-acceleration servo drives on linear axes to handle rapid direction changes.

- CNC Controller & Look-Ahead: This is critical. The CNC must have powerful look-ahead processing (sometimes 1000+ blocks) to anticipate sharp corners and complex paths, dynamically adjusting feed rates to maintain accuracy and prevent "jerky" motion that can damage tools.

- Tooling: Specialized balanced toolholders (like HSK or shrink-fit) ensure minimal runout at high RPM. Advanced cutting tool materials, such as micro-grain carbide and silicon nitride ceramics, coated with Titanium Aluminum Nitride (TiAlN) or similar, are essential to withstand the thermal and mechanical shocks.

- CAM Software: The programming backbone must generate smooth, flowing toolpaths with constant engagement angles. Trochoidal milling and adaptive clearing strategies are staples in HSM CAM, allowing the tool to move in constant-arc engagements, avoiding full-width cuts that would generate excessive heat and force.

Which Materials Are Suitable?

Contrary to intuition, fast machining is highly effective across a broad spectrum, but the parameters change drastically.

- Non-Ferrous Metals (Aluminum, Copper, Brass): These are the classic candidates. High-speed spindles excel here, allowing for extremely high feed rates and mirror-like finishes. For instance, machining aluminum aerospace components at 25,000 RPM and 500+ IPM is standard.

- Steels & Cast Iron: Successful HSM in these materials typically occurs in a lower speed band (8,000-20,000 RPM) but still with elevated feeds. It's particularly beneficial for die and mold machining, where it can drastically reduce hand polishing time on hardened steels (up to 45-55 HRC).

- High-Temperature Alloys (Inconel, Titanium): Here, the goal is not ultra-high RPM but using the HSM principle of light, fast cuts to manage heat. By keeping the chip load light and the feed high, heat is pulled into the chip, preventing work hardening and extending tool life significantly compared to conventional methods.

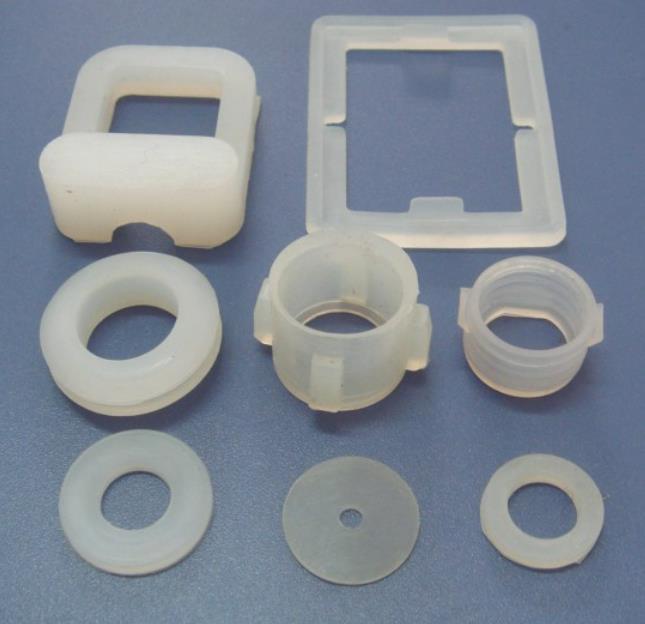

- Composites & Plastics: Fast machining with sharp, specialized tool geometry is key to prevent delamination in composites or melting in thermoplastics. The high speed provides a clean shear cut.

How to Optimize Feed Rates?

Optimization is the heart of fast machining. It's a balancing act between spindle speed (RPM), feed per tooth, and radial/axial depth of cut.

- Start with Manufacturer Data: Always consult cutting tool supplier charts for recommended surface feet per minute (SFM) and chip load (feed per tooth) for your specific material and tool.

- Calculate Baseline Parameters: Use the formulas:

RPM = (SFM x 3.82) / Tool DiameterFeed Rate (IPM) = RPM x Number of Flutes x Chip Load

- Adopt Adaptive Strategies: For roughing, use adaptive toolpaths in your CAM software. These maintain a constant tool engagement (e.g., 10-15% of tool diameter), allowing you to safely increase the programmed feed rate by 150-300% without overloading the tool, as the actual material removal is controlled.

- Implement High-Efficiency Milling (HEM): A subset of HSM, HEM focuses on roughing with larger radial step-overs (up to 15% of tool diameter) but very light axial cuts (5-10% of diameter) and high feeds. This spreads wear evenly along the tool's cutting edge.

- Test, Monitor, and Refine: Begin at 70-80% of the calculated maximum feed. Use spindle load monitoring and listen to the cut. A consistent, high-frequency "hiss" is good; a low-frequency "growl" or chatter indicates a problem.

What Are the Key Benefits?

When implemented correctly, the advantages are transformative:

- Drastically Reduced Cycle Times: Especially for finishing operations and complex 3D contouring, material removal rates can be significantly higher.

- Superior Surface Quality: The high speed and light cut often produce surface finishes so good that secondary polishing or grinding is eliminated, a major cost and time saver in mold making.

- Reduced Machine & Tool Wear: Lower radial forces mean less stress on spindle bearings and machine structure. The favorable heat transfer can also lead to longer tool life in many materials.

- Ability to Machine Thin Walls & Delicate Features: The minimal cutting force allows for the successful machining of fragile aerospace or medical components that would deflect under traditional loads.

- Improved Part Accuracy & Geometry: With less tool pressure and better heat management, part distortion is minimized, and geometric tolerances are easier to hold.

Applications in Modern Manufacturing

- Aerospace: Precisely machining complex, integrated structural components from aluminum billets and titanium forgings.

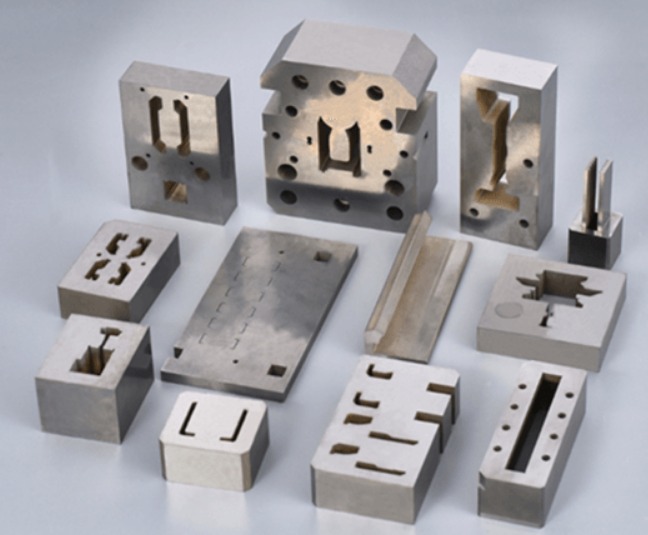

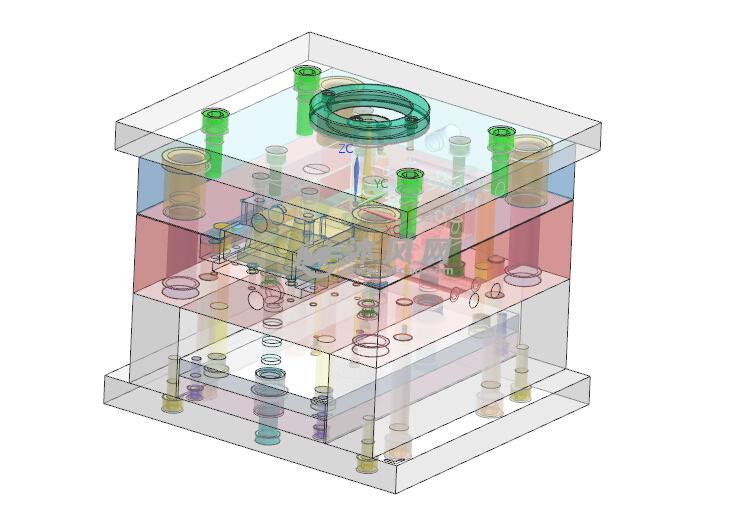

- Die/Mold Making: The quintessential application. HSM is used to directly machine hardened steel molds and electrodes with near-net-shape accuracy, slashing lead times from weeks to days.

- Medical Device Manufacturing: Producing intricate, high-tolerance components from titanium (implants) and specialized plastics (surgical instruments).

- Automotive & Electronics: Creating prototype parts rapidly and producing high-volume precision components like engine blocks or semiconductor fixture plates.

Conclusion

Fast machining is a mature yet continuously evolving discipline that redefines manufacturing efficiency. It is not a simple "turn up the speed" switch but a holistic integration of machine capability, intelligent programming, and process knowledge. By understanding its principles—leveraging high spindle speeds, optimized feed rates, and advanced toolpaths—manufacturers can unlock unprecedented levels of productivity, quality, and capability, staying competitive in an era that demands both speed and precision.

FAQ

Q: Is fast machining only suitable for finishing operations?

A: No. While extremely effective for finishing, the principles are also applied in roughing through strategies like High-Efficiency Milling (HEM), which uses light axial depths and high feed rates to remove material quickly while preserving tool and machine health.

Q: Does fast machining require special coolant?

A: Not always, but effective heat management is key. Many fast machining operations use minimum quantity lubrication (MQL) or even compressed air for non-ferrous metals. For hard materials, high-pressure through-spindle coolant is often critical to break the chip and evacuate heat from the cut zone.

Q: Can my older CNC machine be used for fast machining?

A: It depends. The machine needs a sufficiently high-speed spindle, a fast controller with look-ahead, and excellent rigidity. Retrofitting an old machine for true HSM is often less economical than investing in a dedicated HSM center. However, some fast machining principles, like lighter depths of cut and optimized feeds, can improve performance on many machines.

Q: Is tooling cost much higher for HSM?

A: Initial tooling investment is higher, as it requires precision-balanced holders and premium-grade carbide tools. However, due to often extended tool life and the dramatic reduction in cycle times, the cost per part is typically lower, justifying the upfront expenditure.

Contact Yigu for Custom Manufacturing

At Yigu Technology, we view fast machining not as an isolated technique, but as a core component of our intelligent manufacturing philosophy. We integrate state-of-the-art high-speed machining centers with advanced in-process monitoring and adaptive control systems. This allows us to not only execute complex programs with unmatched precision and speed but also to dynamically adjust parameters in real-time for optimal results.

Our expertise is particularly valuable for projects involving complex geometries, difficult-to-machine materials, and stringent lead-time requirements. We specialize in transforming your most challenging designs into high-integrity components efficiently. Whether you are developing a prototype for the aerospace sector or need production runs for critical medical devices, our fast machining capabilities, backed by deep engineering experience, ensure your project achieves the perfect balance of quality, performance, and speed.

Let's discuss how we can optimize your next manufacturing project. Contact Yigu Technology today for a custom quotation and engineering review.