If you’ve ever needed a part, component, or structure that can’t be bought off the shelf—whether it’s a specialized machine part for your factory, a unique metal frame for a construction project, or a custom enclosure for industrial equipment—custom fabrication services are the solution. At their core, these services involve designing, cutting, shaping, assembling, and finishing materials (like metal, plastic, or wood) to create one-of-a-kind or small-batch products tailored exactly to your specifications. Unlike mass-produced items, custom fabrication prioritizes your unique needs: size, function, durability, and even aesthetic preferences. For businesses, this means no more compromising on ill-fitting standard parts or wasting time modifying off-the-shelf products—custom fabrication delivers a precise fit from day one.

What Materials Are Used in Custom Fabrication Services?

Custom fabrication isn’t limited to one material; the best providers work with a range of substrates to match your project’s requirements. The choice of material depends on factors like strength, weight, corrosion resistance, temperature tolerance, and cost. Below’s a breakdown of the most common options, along with their use cases and real-world examples:

| Material Type | Key Properties | Typical Applications | Real-World Example |

| Carbon Steel | High strength, affordability, easy to weld | Structural frames, machinery bases, shipping containers | A manufacturing plant needed a 12-foot-tall machine base to support a heavy conveyor system. Carbon steel was chosen for its load-bearing capacity, and the fabricator added reinforced welds to handle 5,000+ lbs of weight. |

| Stainless Steel | Corrosion-resistant, hygienic, durable | Food processing equipment, medical tools, outdoor structures | A restaurant chain required custom stainless steel prep tables that could withstand daily cleaning with harsh chemicals. The fabricator used 304 stainless steel (a food-grade alloy) to prevent rust and meet health code standards. |

| Aluminum | Lightweight, corrosion-resistant, malleable | Aerospace components, automotive parts, signage | An aerospace startup needed custom aluminum brackets for a small drone. Aluminum’s low weight (1/3 the density of steel) helped keep the drone’s total weight under 5 lbs, while its strength supported the drone’s camera system. |

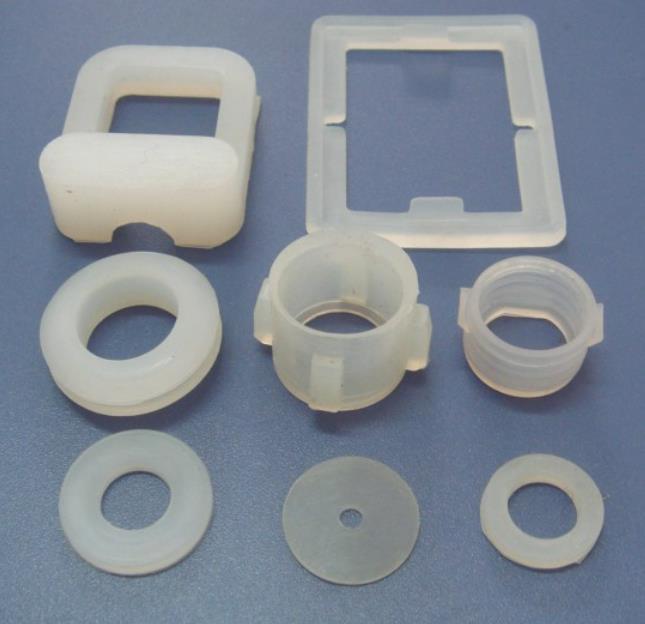

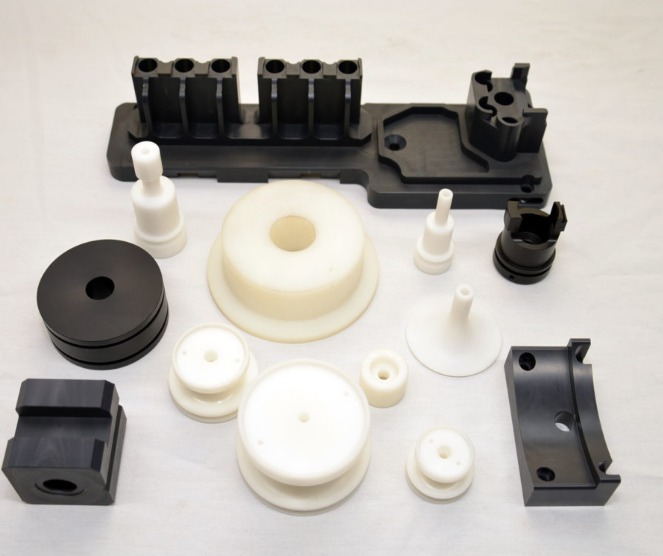

| Plastics (e.g., PVC, HDPE) | Chemical-resistant, low cost, lightweight | Chemical storage tanks, electrical enclosures, consumer goods | A water treatment plant ordered custom HDPE (high-density polyethylene) tanks to store chlorine. HDPE’s resistance to chemical degradation ensured the tanks wouldn’t leach toxins or break down over time. |

| Wood (e.g., plywood, hardwood) | Aesthetic appeal, renewable, easy to shape | Retail displays, furniture, architectural accents | A boutique clothing store wanted custom wooden display racks that matched its rustic brand. The fabricator used reclaimed oak, adding custom notches to hold hangers and LED lighting for product visibility. |

Common Custom Fabrication Processes Explained

Fabricators use a mix of traditional and advanced techniques to turn raw materials into finished products. The process depends on the material, design complexity, and volume, but most projects follow a similar workflow: design → cutting → shaping → assembling → finishing. Here’s a closer look at the key processes, with insights into when each is used:

1. Design & Engineering

Before any physical work begins, fabricators create a detailed design using CAD (Computer-Aided Design) software. This step ensures your vision is translated into precise measurements (down to 0.001 inches for high-precision projects) and that the final product will meet safety and performance standards. Many fabricators also offer DFM (Design for Manufacturability) reviews—this is where their expertise shines. For example, a client once came to us with a CAD design for a metal bracket with a narrow, 0.5-inch slot. Our team noticed the slot would weaken the bracket under load, so we suggested widening it to 0.75 inches and adding a fillet (rounded edge) to distribute stress. The client agreed, and the final bracket lasted 3x longer than their original design would have.

2. Cutting

Cutting is the first step in shaping raw materials. Common methods include:

- Laser Cutting: Uses a high-powered laser to make precise, clean cuts in metal, plastic, or wood. Ideal for complex shapes (like intricate patterns) and thin materials (up to 1 inch for steel).

- Plasma Cutting: Uses a plasma torch to cut through thick metals (up to 6 inches for steel). Faster than laser cutting for heavy materials but leaves a slightly rougher edge.

- Waterjet Cutting: Uses a high-pressure stream of water mixed with abrasives to cut almost any material (even glass or stone). Perfect for heat-sensitive materials (like plastic) that would warp with laser or plasma cutting.

A recent project for a construction company required cutting 200 steel plates into custom hexagonal shapes for a building facade. We used laser cutting for the plates (1/4-inch thick) because it delivered consistent, burr-free edges—saving the client time on post-cutting sanding.

3. Shaping & Forming

Once cut, materials are shaped to match the design. For metals, this often involves:

- Bending: Using a press brake to fold metal into angles (e.g., 90-degree bends for brackets).

- Rolling: Curving metal into cylinders or arcs (e.g., for pipes or tank walls).

- Stamping: Pressing metal into a mold to create 3D shapes (common for small parts like washers).

Plastics might use injection molding (for high-volume projects) or thermoforming (for larger parts like plastic enclosures). For example, a tech startup needed 50 custom plastic enclosures for a new sensor. We used thermoforming instead of injection molding because it required less upfront tooling cost (\(500 vs. \)5,000 for molds)—a critical saving for a small business.

4. Assembly & Welding

After shaping, parts are assembled into the final product. Welding is the most common method for metal:

- MIG Welding: Fast and versatile, used for carbon steel and aluminum.

- TIG Welding: More precise, used for stainless steel and thin materials (e.g., medical equipment).

- Spot Welding: Joins two metal sheets at specific points (common for automotive parts).

For non-metals, assembly might involve gluing (e.g., plastic parts) or screwing (e.g., wooden displays). A furniture manufacturer once hired us to assemble 10 custom reception desks. Each desk had a wooden top, metal legs, and a glass partition—we welded the legs for stability, then glued and clamped the wooden top to ensure it didn’t shift over time.

5. Finishing

Finishing protects the product and enhances its appearance. Common treatments include:

- Painting/Powder Coating: Adds color and corrosion resistance (powder coating is more durable than paint for outdoor use).

- Sandblasting: Removes rust or rough edges, creating a smooth surface.

- Anodizing: For aluminum—creates a hard, protective layer that can be dyed (used for aerospace parts or consumer goods).

A farm equipment company needed custom metal plow blades that could withstand mud and rain. We sandblasted the blades to remove surface imperfections, then applied a powder coating with a matte black finish. The blades resisted rust for 2+ years, compared to 6 months for uncoated blades.

Who Needs Custom Fabrication Services? (Industry Use Cases)

Custom fabrication isn’t just for big manufacturers—it serves businesses across nearly every industry. Below are the most common sectors, with specific examples of how fabrication solves their unique challenges:

Manufacturing & Industrial

Factories often need custom parts to repair or upgrade machinery. For example, a textile mill’s conveyor belt broke, and the original part was discontinued. A fabricator created a custom metal roller (matching the original’s diameter and shaft size) in 3 days—getting the mill back to full production 2 weeks faster than waiting for a generic replacement.

Construction & Architecture

Builders and architects use custom fabrication for structural elements and design features. A luxury hotel under construction wanted a curved stainless steel staircase (a key design focal point). The fabricator used 3D modeling to test the curve’s stability, then rolled and welded stainless steel plates to create the steps. The final staircase met building codes and exceeded the architect’s aesthetic expectations.

Automotive & Aerospace

These industries demand high-precision parts. An electric vehicle (EV) startup needed custom aluminum battery trays that fit into a tight undercarriage space. The fabricator used CNC machining (a computer-controlled process) to cut the trays to 0.005-inch precision, ensuring they held the batteries securely without adding extra weight (critical for EV range).

Food & Beverage

Hygiene and compliance are top priorities here. A craft brewery needed custom stainless steel fermentation tanks with built-in temperature sensors. The fabricator used food-grade 316 stainless steel (resistant to beer’s acidic properties) and welded the sensors into the tank walls—eliminating gaps where bacteria could grow.

Healthcare & Medical

Medical equipment requires biocompatible materials and strict precision. A hospital needed custom plastic trays to hold surgical tools (each tray had to fit a specific set of instruments). The fabricator used FDA-approved plastic and laser-cut the trays to exact dimensions, ensuring tools stayed organized and sterile during procedures.

How to Choose the Right Custom Fabrication Partner (Step-by-Step Guide)

Choosing a fabricator is one of the most important decisions for your project—pick the wrong one, and you could end up with delayed timelines, low-quality work, or unexpected costs. Follow these steps to find a partner that aligns with your needs:

Step 1: Define Your Project Requirements Clearly

Before reaching out to fabricators, answer these questions:

- What’s the final product (e.g., “custom metal bracket for a pump”)?

- What material do you need (or do you need help choosing one)?

- What are the key specs (size, weight, load capacity, tolerances)?

- What’s your timeline (e.g., “3 weeks from design to delivery”)?

- What’s your budget range?

A clear brief helps fabricators give accurate quotes and avoids miscommunication. For example, a client once told us they needed “a custom metal box”—we had to follow up with 10+ questions (size? material? waterproof? locking mechanism?) before we could provide a quote. This added a week to the project timeline—something you can avoid with a detailed brief.

Step 2: Check Their Expertise in Your Material/Industry

Not all fabricators specialize in every material. A shop that excels at wood fabrication might not have the equipment or experience for stainless steel welding. Ask:

- Do you have experience working with [your material, e.g., “aluminum”]?

- Have you done projects for [your industry, e.g., “food processing”]?

- Can you share examples of similar projects (portfolios or case studies)?

For high-stakes projects (like medical equipment), look for certifications: ISO 9001 (quality management) or AS9100 (aerospace standards). A fabricator with these certifications has proven processes to ensure consistency and compliance.

Step 3: Evaluate Their Technology & Capacity

Advanced equipment leads to better quality and faster turnaround. Ask:

- Do you use CAD/DFM software for design?

- What cutting/shaping tools do you have (e.g., laser cutters, press brakes)?

- Can you handle your project volume (e.g., “100 parts” vs. “1 part”)?

A small shop with a single laser cutter might struggle to meet a 2-week deadline for 500 parts, while a larger shop with multiple machines can scale up easily.

Step 4: Review Customer Feedback & References

Don’t just take the fabricator’s word for it—check their reputation:

- Look for reviews on Google, Yelp, or industry forums (e.g., Fabricator.com).

- Ask for 2-3 customer references and call them. Ask:

- Did the fabricator meet the timeline and budget?

- Was the quality up to your standards?

- How did they handle issues (e.g., design changes, delays)?

A fabricator we worked with once had great online reviews, but when we called a reference, we learned they often missed deadlines for large projects. We adjusted our timeline accordingly—and avoided a costly delay.

Step 5: Compare Quotes (But Don’t Just Pick the Cheapest)

Quotes will vary based on material, complexity, and shop overhead. When comparing, look beyond the total cost:

- Does the quote include all steps (design, cutting, finishing, delivery)?

- Are there any hidden fees (e.g., for design revisions, rush orders)?

- What’s the warranty on the work (e.g., “1 year for welding defects”)?

The cheapest quote might cut corners—for example, using a lower-grade material or skipping a finishing step. A slightly higher quote that includes DFM reviews and a warranty is often a better long-term investment.

Key Benefits of Custom Fabrication (vs. Off-the-Shelf Products)

Why choose custom fabrication over buying standard parts? Here are the biggest advantages, backed by data and examples:

1. Perfect Fit for Your Unique Needs

Off-the-shelf products are designed for “average” use cases—they might be too big, too small, or lack a feature you need. Custom fabrication eliminates this problem. A study by the Fabricators & Manufacturers Association (FMA) found that 78% of businesses that use custom fabrication report fewer equipment breakdowns, because parts fit exactly and work as intended. For example, a packaging company was using a standard conveyor belt that kept jamming (the belt was 2 inches wider than needed). A custom belt (cut to the exact width of their machines) reduced jams by 90%—saving them 10 hours of downtime per week.

2. Improved Durability & Longevity

Custom fabricators can select materials and processes to match your product’s operating conditions. For example, if your part will be exposed to saltwater (e.g., marine equipment), a fabricator can use marine-grade stainless steel (316) instead of standard stainless steel (304). The FMA study also found that custom-fabricated parts last 2-3x longer than off-the-shelf alternatives, because they’re built to withstand specific wear and tear.

3. Cost Savings Over Time

Custom fabrication often has a higher upfront cost than off-the-shelf parts—but it saves money long-term. Here’s why:

- No need to modify standard parts (e.g., cutting, drilling, or sanding) to make them fit—saves labor time.

- Fewer breakdowns (thanks to better fit and durability)—reduces repair costs and downtime.

- No wasted inventory (you only order what you need)—avoids storing unused standard parts.

A construction company we worked with calculated that custom steel beams cost 15% more upfront than standard beams—but they saved 30% over 5 years because the custom beams didn’t need repairs and the company didn’t have to store extra standard beams.

4. Flexibility for Design Changes

Off-the-shelf products can’t be modified—if you need a slightly different size or feature, you’re out of luck. Custom fabricators can adjust designs quickly, even mid-project. For example, a tech company was having a custom plastic enclosure made for a new router. Halfway through production, they realized the enclosure needed an extra vent to prevent overheating. The fabricator adjusted the CAD design and laser-cut the vents into the remaining enclosures—adding just 1 day to the timeline and $50 to the cost.

5. Competitive Advantage

Custom fabrication lets you create unique products or processes that your competitors can’t replicate. A bakery used custom fabrication to build a one-of-a-kind dough mixer that could handle 50% more dough than standard mixers. This let them increase production without hiring extra staff—helping them capture 20% more market share in their region.

Potential Challenges of Custom Fabrication (and How to Avoid Them)

While custom fabrication offers many benefits, it’s not without challenges. Here are the most common issues and how to mitigate them:

Challenge 1: Longer Lead Times

Custom projects take time—design, material sourcing, and production can take 2-6 weeks (vs. 1-2 days for off-the-shelf parts). To avoid delays:

- Plan ahead: Start the fabrication process 4-6 weeks before you need the final product.

- Prioritize design approvals: Review CAD designs quickly (within 1-2 days) to keep the project on track.

- Choose a fabricator with in-house material sourcing: Shops that stock common materials (like carbon steel or aluminum) can start production faster than those that need to order materials.

Challenge 2: Higher Upfront Costs

As mentioned earlier, custom fabrication has a higher initial cost. To manage budgets:

- Be clear about your “must-haves” vs. “nice-to-haves”: For example, a powder coat finish might be a “nice-to-have” if your part is indoors and won’t be exposed to moisture.

- Ask for a detailed quote breakdown: This lets you see where costs are coming from (e.g., “\(500 for laser cutting, \)300 for welding”) and identify areas to save.

- Consider small-batch production: If you don’t need 100 parts right away, order 20-30 first to test the design—then scale up later.

Challenge 3: Design Miscommunication

A misinterpreted design can lead to wasted materials and time. To avoid this:

- Use 3D renderings: Ask the fabricator to provide a 3D model of your design—this makes it easier to visualize the final product than a 2D CAD drawing.

- Request a prototype: For complex projects, order a single prototype before full production. This lets you test the fit and function and make changes before investing in large-scale manufacturing.

- Have regular check-ins during the design phase: Schedule short calls (15-20 minutes) to review progress and address questions. This prevents small misunderstandings from turning into big problems later.

Yigu Technology’s Perspective on Custom Fabrication Services

At Yigu Technology, we believe custom fabrication services are no longer a “nice-to-have” but a strategic necessity for businesses aiming to stay agile and competitive. In our work with clients across manufacturing, aerospace, and healthcare, we’ve seen firsthand how off-the-shelf products often limit innovation—forcing teams to adapt their processes to fit standard parts, rather than building parts that fit their unique workflows.

What sets effective custom fabrication apart, in our view, is the fusion of technical expertise and collaborative design. Many businesses overlook the value of DFM (Design for Manufacturability) reviews, but these are where true efficiency is unlocked. For example, we recently partnered with a EV component maker that initially designed a battery housing with multiple small, hard-to-weld sections. Our team suggested simplifying the design to reduce weld points, cutting production time by 25% and improving structural integrity.

We also emphasize transparency—especially around costs and timelines. Clients shouldn’t have to guess what’s included in a quote or why a project is delayed. By sharing detailed breakdowns (e.g., material costs, machine time) and providing weekly progress updates, we help businesses plan with confidence. Ultimately, custom fabrication should solve problems, not create new ones—and that’s the standard we hold ourselves to.

FAQ About Custom Fabrication Services

1. How long does a typical custom fabrication project take?

Timelines vary based on complexity, material availability, and volume, but most projects take 2-6 weeks. Simple parts (e.g., a custom metal bracket) might be ready in 2 weeks, while complex projects (e.g., a custom stainless steel staircase) could take 4-6 weeks. To speed up the process, have a clear design brief ready and choose a fabricator with in-house material stock.

2. Can custom fabrication handle small-batch orders (e.g., 5-10 parts)?

Absolutely. Unlike mass production, which requires expensive tooling for large volumes, custom fabrication is ideal for small batches. Many fabricators even offer “low-volume” discounts for orders between 5-50 parts. This makes it perfect for startups testing a new product or businesses needing replacement parts for older machinery.

3. What if I don’t have a CAD design for my project?

Most fabricators offer design services—they can turn your sketches, photos, or verbal descriptions into a detailed CAD design. Be prepared to share specifics: dimensions, intended use, material preferences, and any safety standards (e.g., FDA for medical parts). Some fabricators charge a small design fee, but this is often worth it to ensure the final product meets your needs.

4. Are there materials that can’t be used in custom fabrication?

Virtually any solid material can be fabricated, but some are more challenging (and costly) than others. For example, exotic metals like titanium require specialized welding equipment and expertise, which not all fabricators have. Similarly, brittle materials like glass or ceramic need waterjet cutting (not laser or plasma) to avoid cracking. A good fabricator will tell you if a material is impractical for your project and suggest alternatives.

5. What kind of warranty do custom fabrication services offer?

Warranties typically cover defects in workmanship (e.g., weak welds, incorrect cuts) for 6 months to 1 year. Some fabricators offer longer warranties (2-3 years) for high-quality materials like stainless steel or aluminum. Be sure to ask for the warranty in writing—this should outline what’s covered (e.g., free repairs or replacements) and what’s not (e.g., damage from misuse).