1. Introduction

1.1 Definition of Beam Deposition Process in Additive Manufacturing

The beam deposition process in additive manufacturing, also known as Directed Energy Deposition (DED), is a revolutionary manufacturing technology. It involves the use of a high - energy beam, such as a laser beam, electron beam, or plasma arc, to melt and deposit materials layer by layer.

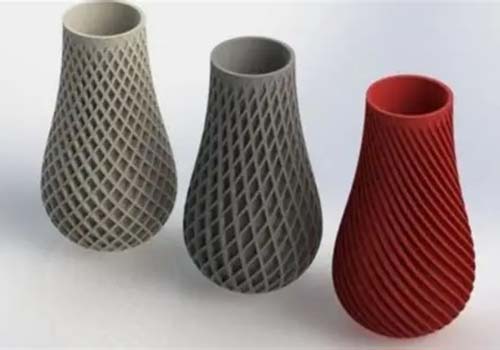

Typically, metal powders or wire materials are fed into the molten pool created by the energy beam. As the beam moves along a pre - defined path controlled by a computer - aided design (CAD) model, the melted material solidifies, gradually building up a three - dimensional object. This process allows for the creation of complex geometries that are difficult or impossible to achieve with traditional manufacturing methods. For example, internal channels, lattice structures, and intricate shapes can be fabricated directly, without the need for multiple assembly steps.

2. Working Principle

2.1 Basic Mechanism

The beam deposition process in additive manufacturing operates on a layer - by - layer material deposition principle. When using a laser beam deposition system, for example, a high - power laser is focused onto a substrate. The intense energy from the laser rapidly raises the temperature of the targeted area to the melting point or even the boiling point of the material.

Metal powders are then precisely delivered into the molten pool created by the laser beam. As the laser moves along a predefined path based on the CAD model, the molten metal solidifies almost immediately upon leaving the high - energy zone. This solidified material forms a thin layer, and subsequent layers are deposited on top of the previous ones. Each layer is typically in the range of 0.1 - 1 mm in thickness, depending on the specific requirements of the part being manufactured.

In the case of electron beam deposition, an electron gun generates a high - velocity beam of electrons. These electrons are accelerated to high speeds and focused onto the material. The kinetic energy of the electrons is converted into heat energy when they strike the material, melting it. Similar to laser beam deposition, the melted material solidifies as the electron beam moves, creating layers that build up the 3D structure.

2.2 Key Components and Their Functions

- Laser/ Electron Gun:

- Function in Laser Beam Deposition: The laser is the primary energy source in laser - based beam deposition. It provides the intense heat required to melt the material. High - power fiber lasers or CO₂ lasers are commonly used. For instance, a fiber laser can have a power output ranging from 100 W to several kilowatts, depending on the application. The higher the power, the faster the melting process and potentially the larger the volume of material that can be processed in a given time.

- Function in Electron Beam Deposition: The electron gun in electron beam deposition is responsible for generating and accelerating electrons. It consists of a cathode, which emits electrons when heated, and an anode, which accelerates the electrons to high velocities. The electron beam can be precisely controlled in terms of its position, intensity, and focus, allowing for accurate melting of the material.

- Powder Delivery System:

- This system is crucial for both laser and electron beam deposition processes. It precisely delivers the metal powder to the molten pool. There are two main types of powder delivery systems: co - axial and off - axis.

- Co - axial Powder Delivery: In a co - axial system, the powder is delivered through a nozzle that is concentric with the laser or electron beam. This ensures that the powder is evenly distributed around the beam and has a high probability of being melted. It is often used for complex geometries where uniform powder distribution is essential.

- Off - axis Powder Delivery: In an off - axis system, the powder is delivered from a side - mounted nozzle. This type of system is more suitable for certain applications where the geometry of the part or the process requirements make co - axial delivery less practical. The powder flow rate can be adjusted based on the speed of the beam and the thickness of the layer being deposited. For example, for a small, intricate part, a lower powder flow rate may be required to ensure precise deposition, while a larger part may need a higher flow rate to build up the layers more quickly.

- Substrate and Build Platform:

- The substrate provides a starting point for the deposition process. It is usually made of a material that is compatible with the deposited material, such as a metal plate for metal - based additive manufacturing. The build platform, on which the substrate is placed, is often movable and can be precisely controlled in the X, Y, and Z axes. This allows for the accurate positioning of the part during the deposition process. For example, the build platform may move downwards by a precise amount (equal to the thickness of a single layer) after each layer is deposited, ensuring that the next layer is deposited in the correct position.

3. Types of Beam Deposition Processes

3.1 Laser - based Beam Deposition

Laser - based beam deposition, also known as Laser Metal Deposition (LMD) or Laser Engineered Net Shaping (LENS), is one of the most common beam deposition processes in additive manufacturing.

Characteristics: In this process, a high - power laser beam is used as the energy source to melt the powder or wire feedstock. The laser beam has a high energy density, which allows for precise control of the melting process. The spot size of the laser beam can be adjusted to a very small diameter, typically in the range of 0.1 - 1 mm, enabling the deposition of very fine details.

Advantages:

- High Precision: It can achieve high - resolution and accurate deposition, making it suitable for manufacturing parts with complex geometries and tight tolerances. For example, in the production of micro - mechanical components, laser - based beam deposition can create features with dimensions as small as a few micrometers.

- Wide Material Compatibility: It can process a wide range of materials, including metals (such as titanium, aluminum, stainless steel, and nickel - based alloys), ceramics, and some polymers. A study showed that over 90% of the commonly used engineering materials can be processed using laser - based beam deposition techniques.

- Fast Deposition Rate: The high - energy laser can quickly melt the material, resulting in a relatively fast deposition rate. Depending on the power of the laser and the type of material, the deposition rate can range from several grams per minute to tens of grams per minute.

Applicable Materials:

- Metals: Titanium alloys are widely used in aerospace applications due to their high strength - to - weight ratio. Laser - based beam deposition can produce titanium alloy components with excellent mechanical properties, such as high fatigue resistance. Stainless steel is another common material processed by this method, which is used in applications where corrosion resistance is required, like in the medical and food industries.

- Ceramics: Ceramics processed by laser - based beam deposition have high hardness, wear resistance, and high - temperature resistance. They can be used in applications such as cutting tools, engine components in high - temperature environments, and thermal barrier coatings.

3.2 Electron Beam Deposition

Electron beam deposition, specifically Electron Beam Melting (EBM), is another important beam deposition process.

Principle: In electron beam deposition, a beam of high - energy electrons is generated by an electron gun in a vacuum environment. When the electron beam strikes the material, the kinetic energy of the electrons is converted into heat energy, melting the material. The vacuum environment is crucial as it reduces the scattering of electrons and prevents oxidation of the molten material.

Characteristics:

- High - Energy Source: The electron beam can provide a very high energy density, even higher than some laser beams in certain cases. This allows for rapid melting of the material, which can be beneficial for high - speed manufacturing.

- Vacuum - based Process: Operating in a vacuum, it reduces the risk of contamination from the atmosphere. This is particularly important for materials that are highly reactive with oxygen or other gases in the air, such as titanium.

Advantages in Specific Fields:

- Aerospace Applications: EBM is highly valued in the aerospace industry. For example, it can be used to manufacture large - scale, complex - shaped aerospace components. The high - energy electron beam can quickly melt and deposit materials, reducing manufacturing time. Also, the vacuum environment ensures the purity of the deposited material, which is essential for the high - performance requirements of aerospace components. Components made by EBM have shown excellent mechanical properties, with a 20% increase in tensile strength compared to some traditional manufacturing methods for certain aerospace - grade alloys.

- Medical Implant Manufacturing: In the medical field, EBM is used to create custom - made implants. The ability to precisely control the deposition process allows for the creation of implants with complex porous structures. These porous structures can promote tissue ingrowth, improving the integration of the implant with the surrounding tissue. For instance, EBM - made titanium hip implants have shown better long - term stability in patients, reducing the need for revision surgeries.

4. Materials Used in Beam Deposition Process

4.1 Metal Materials

- Titanium Alloys: Titanium alloys are highly favored in beam deposition processes due to their exceptional strength - to - weight ratio, corrosion resistance, and biocompatibility. For example, Ti - 6Al - 4V is one of the most commonly used titanium alloys in additive manufacturing. It has a density of about 4.43 g/cm³, which is much lower than that of steel, making it ideal for applications where weight reduction is crucial, such as in the aerospace industry. In beam deposition, titanium alloys can achieve high - strength components with a tensile strength of up to 900 - 1100 MPa, depending on the processing conditions and heat treatment. Their biocompatibility also makes them suitable for medical implants, where the beam deposition process can create complex, patient - specific implant shapes.

- Aluminum Alloys: Aluminum alloys are another important group of materials used in beam deposition. They are known for their low density (around 2.7 g/cm³), high thermal conductivity, and good formability. Alloys like 6061 and 7075 are popular. Aluminum 6061, which contains magnesium and silicon, has good corrosion resistance and moderate strength. In beam deposition, it can be used to manufacture lightweight components for the automotive and aerospace industries. The deposited aluminum alloy parts can have a yield strength of 240 - 310 MPa, and their high thermal conductivity is beneficial in applications where heat dissipation is required, such as in engine components.

- Stainless Steels: Stainless steels, such as 316L and 17 - 4PH, are used in beam deposition for their excellent corrosion resistance and mechanical properties. 316L, with its high chromium and nickel content, offers superior corrosion resistance in various environments, including marine and chemical processing environments. In beam deposition, it can be used to create components for the food and beverage industry, chemical plants, and medical equipment. The deposited 316L stainless steel parts can have a tensile strength of around 485 - 620 MPa. 17 - 4PH is a precipitation - hardened stainless steel, which can achieve high strength through heat treatment. It is often used in applications where high strength and corrosion resistance are both required, such as in aerospace fasteners and oil and gas industry components.

4.2 Non - metal Materials

- Ceramics: Ceramics are non - metallic, inorganic materials that can be processed using beam deposition techniques. They have high hardness, excellent wear resistance, and high - temperature resistance. For example, alumina (Al₂O₃) ceramics are widely used. In beam deposition, alumina ceramics can be used to create components for cutting tools, where their high hardness (Mohs hardness of around 9) allows for efficient material removal. They are also used in the production of thermal barrier coatings for engines. These coatings can withstand high temperatures up to 1500 °C or more, protecting the underlying metal components from heat damage. Another example is silicon carbide (SiC) ceramics, which have high thermal conductivity and good mechanical properties at high temperatures. They can be used in applications such as semiconductor manufacturing equipment, where their heat - dissipation and high - temperature stability are crucial.

- Polymers: Some polymers can also be processed by beam deposition. For instance, polyetheretherketone (PEEK) is a high - performance polymer with excellent chemical resistance, high - temperature stability, and good mechanical properties. In beam deposition, PEEK can be used to create components for the aerospace and medical industries. In aerospace, PEEK components can replace metal parts in some non - load - bearing applications, reducing weight while maintaining performance. In the medical field, PEEK is used to create custom - made prosthetics due to its biocompatibility. It can withstand sterilization processes and has a tensile strength of about 90 - 100 MPa, making it suitable for applications where mechanical strength is required in the human body environment.

5. Yigu Technology's View

As a non - standard plastic metal products custom Supplier, Yigu Technology highly values the beam deposition process in additive manufacturing. This technology has brought new vitality to the field of custom - made products.

For non - standard plastic and metal products, the beam deposition process allows for the creation of highly customized parts with complex geometries. It reduces the need for expensive molds and complex machining processes in traditional manufacturing, which is especially cost - effective for small - batch production. Yigu Technology believes that the high precision and material flexibility of beam deposition can meet the diverse needs of customers in different industries. For example, in producing custom - made plastic components with intricate internal structures for the electronics industry, or metal parts with unique shapes for the machinery industry, the beam deposition process enables faster production cycles and higher - quality products. By leveraging this technology, Yigu Technology aims to provide more innovative and high - quality solutions to its customers, further expanding the possibilities in the non - standard product customization market.