Introduction to Transparent 3D Printing

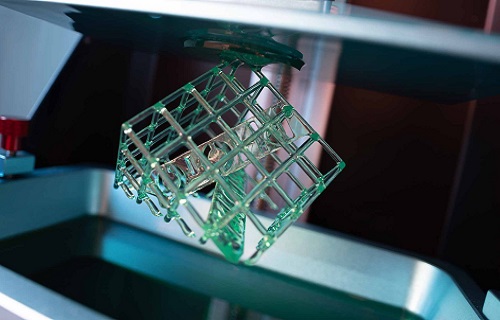

Transparent 3D printing marks a pivotal evolution in the realm of additive manufacturing, enabling the production of see-through objects with remarkable precision. This groundbreaking technology harnesses specialized materials and cutting-edge methods to craft intricate designs that reveal internal structures. By fabricating transparent objects, industries across various fields have unlocked new potential, offering both functional and aesthetic benefits.

Definition and Principles

Transparent 3D printing is a process that builds objects layer by layer, utilizing materials that permit light to pass through them. Unlike traditional opaque prints, achieving transparency requires specific resins or polymers that can be cured to attain optical clarity. The most common techniques used in transparent 3D printing include Stereolithography (SLA) and Digital Light Processing (DLP), both of which employ light to solidify photopolymer resins, enabling the creation of intricate, clear objects.

Evolution of 3D Printing Technology

The inception of 3D printing dates back to the mid-1980s, when Charles Hull invented stereolithography. Over time, this technology has undergone significant advancements, evolving to include diverse printing techniques and materials. Transparent 3D printing emerged as a natural extension of these developments, driven by a growing demand for more sophisticated, visually compelling models. While earlier attempts at transparency faced quality limitations, continuous improvements have now enabled the production of high-resolution, clear prints.

Materials Used in Transparent 3D Printing

Types of Transparent Resins and Polymers

A wide variety of transparent resins and polymers are utilized in 3D printing, each offering distinct characteristics suited for different uses:

- Acrylic-Based Resins: These are favored for their balance between clarity and mechanical strength, making them ideal for applications such as eyeglasses, lenses, and decorative items.

- Epoxy Resins: Renowned for their exceptional strength and heat resistance, epoxy resins find frequent use in industrial and functional applications.

- Polycarbonate (PC): Offering remarkable impact resistance, polycarbonate is commonly used in safety equipment like protective eyewear.

- Polymethyl Methacrylate (PMMA): Known as acrylic glass, PMMA is valued for its high optical clarity and weather resistance, often used in architectural displays and models.

- Silicone-Based Resins: These resins provide flexibility and softness, suitable for applications that require transparent, pliable components.

Material Properties and Behavior

The unique properties of each transparent material greatly influence its application. For example, acrylic resins are highly suitable for creating fine, detailed models due to their low viscosity, while polycarbonate offers superior durability for more functional parts. Understanding these material behaviors is key to selecting the best option for a given project.

Techniques and Processes

Layer-by-Layer Fabrication

Transparent 3D printing operates on the same fundamental principle as traditional 3D printing: the object is built layer by layer. However, achieving true transparency requires meticulous control over various parameters, such as layer thickness, exposure time, and curing conditions. The objective is to reduce visible layer lines and ensure uniform curing, which minimizes cloudiness and enhances clarity.

Post-Processing for Transparency

Post-processing plays a vital role in refining the clarity of transparent 3D prints. Key steps include:

- Support Removal: Removing supports with precision is crucial for preserving the clarity and integrity of the print.

- Sanding and Polishing: These processes eliminate surface imperfections and smooth out the print’s surface to enhance its transparency.

- Annealing: For certain materials, annealing helps alleviate internal stresses, further improving optical clarity.

- Coating: A clear protective coating can boost transparency while also shielding the surface from scratches and other damage.

Applications of Transparent 3D Printing

Medical and Scientific Visualization

In the medical sector, transparent 3D printing is transforming the way complex anatomical structures are visualized and studied. Surgeons can now practice on realistic, see-through models of organs, which improves surgical precision. Additionally, researchers utilize transparent models to study biological tissues and cellular structures, aiding in both educational and diagnostic purposes.

Architectural and Design Modeling

Architects and designers use transparent 3D printing to create visually compelling models that showcase both the external and internal features of structures and products. These models serve a dual purpose: they are not only visually striking but also highly functional, helping stakeholders better understand design concepts. The transparency allows for a more accurate representation of structural elements, lighting effects, and spatial relationships that would be difficult to depict with opaque models.

Entertainment and Visual Effects

The entertainment industry widely adopts transparent 3D printing to create eye-catching props and set pieces. From movie props to stage designs, the ability to produce see-through objects adds an exciting new dimension to storytelling and audience engagement. Special effects teams also rely on this technology to craft realistic illusions and enhance visual effects in both films and TV shows.

FAQs

What are the main advantages of using transparent 3D printing?

Transparent 3D printing offers numerous advantages, including the ability to visualize internal structures, enhanced visual appeal, and improved functionality in a variety of applications. It enables the creation of detailed, see-through models for educational, diagnostic, and design purposes. Additionally, transparent prints provide a unique way to highlight specific features and details that would otherwise be hidden in opaque models.

What materials are commonly used for transparent 3D printing?

The most common materials for transparent 3D printing include acrylic-based resins, epoxy resins, polycarbonate (PC), polymethyl methacrylate (PMMA), and silicone-based resins. Each of these materials boasts unique properties, such as high optical clarity, superior impact resistance, and flexibility, making them suitable for different applications.

How does post-processing affect the transparency of 3D prints?

Post-processing is crucial for enhancing the transparency of 3D prints. Steps like support removal, sanding, polishing, annealing, and applying a clear coating help reduce surface imperfections, minimize internal stresses, and improve the overall optical clarity of the print. Proper post-processing ensures that the final product achieves the desired level of transparency and visual appeal.