Introduction to MJF 3D Printing

Multi-Jet Fusion (MJF) 3D printing is a revolutionary additive manufacturing technology that has rapidly gained prominence in the industrial world. This advanced process offers exceptional speed, strength, and precision, making it a powerful tool for industries ranging from aerospace to automotive and healthcare. Unlike other 3D printing technologies, MJF uses a binder jetting process, creating complex geometries and functional prototypes with remarkable accuracy. In this article, we will examine how MJF 3D printing is transforming modern manufacturing practices and driving innovation in various sectors.

Definition and Principles

MJF 3D printing, developed by Hewlett Packard (HP), operates using a powder bed fusion technique. It involves applying a fusing agent and a detailing agent selectively to a bed of nylon powder, layer by layer. This binder jetting process fuses the powder particles together to create a solid structure, while the detailing agent ensures high-resolution details and finishes. The process continues layer by layer until the object is fully formed.

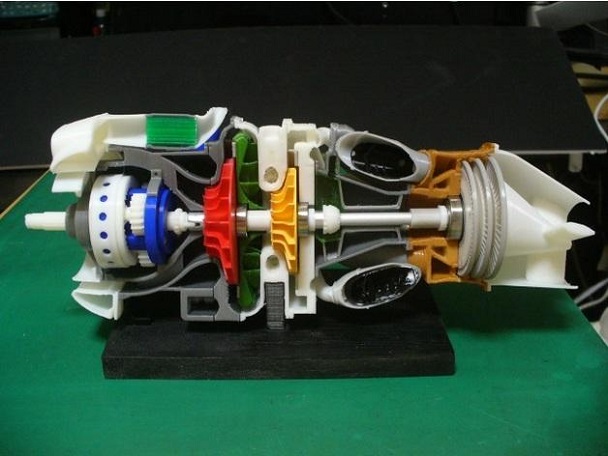

Key components of an MJF 3D printer include:

- Powder Bed: A flat platform where a layer of nylon powder is deposited.

- Inkjet Printhead: This applies the fusing and detailing agents to the powder.

- Spreading Mechanism: Ensures the even distribution of the powder.

- Heating Element: Heats the powder bed to enable bonding and sintering of the layers.

Comparison with Other 3D Printing Technologies

While MJF shares similarities with other 3D printing methods, such as Selective Laser Sintering (SLS) and Fused Deposition Modeling (FDM), it offers several notable advantages:

- Speed: MJF is faster than SLS because it prints multiple layers simultaneously using a wide array of inkjet nozzles, whereas SLS prints one layer at a time with a laser.

- Detail and Complexity: MJF can achieve finer details and more complex geometries than FDM, which struggles with intricate designs and overhangs.

- Surface Finish: Parts printed with MJF have a smoother finish, reducing the need for significant post-processing compared to SLS or FDM prints.

- Material Strength: MJF components offer higher mechanical properties and durability, making them suitable for functional prototypes and end-use parts.

Applications of MJF 3D Printing

Aerospace Industry

MJF 3D printing is making a substantial impact on the aerospace sector, where precision, weight reduction, and material efficiency are crucial. With MJF, manufacturers can produce lightweight yet strong components such as brackets, clips, and internal structures. The ability to quickly iterate on designs and produce customized parts accelerates the development of aircraft components, ultimately improving performance, fuel efficiency, and safety.

Automotive Sector

The automotive industry benefits greatly from MJF 3D printing by enabling the production of high-strength, high-precision components. For example, MJF can be used to create dashboard parts, engine components, and functional prototypes for rigorous testing. This ability to produce functional, tested prototypes in a fraction of the time compared to traditional methods enhances vehicle performance, safety, and reduces overall development time.

Medical Field

In healthcare, MJF is transforming the production of medical devices, implants, and prosthetics. MJF allows for the creation of custom prosthetics, orthotics, and surgical guides that are tailored to the specific needs of individual patients. Additionally, the biocompatible materials used in MJF ensure these medical products are safe for human use. The speed and precision of MJF also help accelerate the development of medical devices, leading to better patient outcomes and faster delivery of critical healthcare products.

Advantages of MJF 3D Printing

Speed and Efficiency

MJF is one of the fastest 3D printing technologies, capable of producing parts up to 10 times faster than traditional 3D printing methods. This efficiency is critical in industries where reducing time-to-market is essential. The speed of MJF makes it a highly attractive solution for companies looking to rapidly prototype and manufacture functional parts.

Strength and Durability

MJF printed parts are known for their exceptional mechanical strength and durability. The nylon-based materials used in MJF, combined with the precise application of the fusing agent, result in parts that can endure high stress and wear. This makes MJF ideal for functional prototypes and end-use parts in industries like aerospace and automotive, where part strength is crucial.

Detail and Complexity

MJF 3D printing allows the creation of highly detailed, intricate geometries that would be difficult or impossible to achieve with traditional manufacturing methods. The technology enables designers to explore new design possibilities and produce parts with complex internal features, reducing the need for assembly and improving the efficiency of the final product.

Challenges and Limitations

Material Constraints

While MJF is a versatile technology, it is currently limited primarily to nylon-based materials. This restriction can be a challenge for applications that require metals, high-temperature plastics, or other specialized materials. However, research is ongoing to expand the range of materials available for MJF, which may lead to broader applications in the future.

Cost Considerations

One of the challenges of adopting MJF 3D printing is the initial investment required for the equipment and materials. The cost of MJF machines and their maintenance can be substantial, making it less accessible for small businesses or startups. However, as the technology matures and production scales, costs are likely to decrease, making MJF more affordable for a wider range of companies.

Post-Processing Requirements

Despite the relatively smooth surface finish that MJF parts offer, some level of post-processing may still be required. This could include sanding, painting, or additional treatments to enhance the aesthetic or functional properties of the printed parts. The need for post-processing can add to the overall cost and time required to complete the production of the final part.

FAQs

What is Multi-Jet Fusion (MJF) 3D printing?

Multi-Jet Fusion (MJF) is an advanced 3D printing technology developed by Hewlett Packard (HP). It uses a binder jetting process to create parts by selectively applying fusing and detailing agents to a powder bed of nylon particles. The process builds objects layer by layer, with the ability to produce complex geometries, high strength, and fast production speeds.

What are the primary advantages of MJF 3D printing?

The primary advantages of MJF 3D printing include:

- Speed: MJF is up to ten times faster than traditional 3D printing methods.

- Strength and Durability: The printed parts exhibit exceptional mechanical properties, suitable for functional prototypes and end-use applications.

- Detail and Complexity: MJF enables the production of highly detailed and intricate designs with complex geometries.

In which industries is MJF 3D printing particularly beneficial?

MJF 3D printing is particularly beneficial in industries such as aerospace, automotive, and medical. These sectors require precision, strength, and the ability to quickly produce customized and complex parts. MJF enables faster development cycles and higher-quality components, improving performance and reducing time-to-market.