Stereolithography 3D printing, often referred to as SLA (Stereolithography Apparatus), is a widely used additive manufacturing technology that utilizes ultraviolet (UV) light to cure liquid resin into solid objects, layer by layer. This method is known for its high resolution, precision, and ability to produce intricate and detailed parts. SLA has a broad range of applications, including prototyping, creating complex parts in industries such as aerospace, automotive, medical, and dental, as well as in the creation of art and jewelry.

Introduction to Stereolithography 3D Printing

Stereolithography 3D printing has revolutionized industries by allowing the creation of highly accurate and detailed three-dimensional objects. Unlike traditional manufacturing processes that remove material from a larger block, SLA builds objects layer by layer through a process known as photopolymerization. This ability to create complex geometries, which are difficult or impossible to achieve with conventional methods, has made SLA a critical tool in many industries.

Definition and Basic Principles

SLA 3D printing was first coined by Charles Hull in the 1980s, and the technology is based on the principle of using a UV laser or projector to solidify photopolymer resin. The resin is contained in a vat and exposed to a light source that hardens it where illuminated. This process is repeated layer by layer to gradually form a complete three-dimensional object. The SLA printer controls the movement of the light source and the build platform to build parts with exceptional precision.

Comparison with Other 3D Printing Technologies

Compared to other 3D printing methods like Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and Digital Light Processing (DLP), SLA offers unique advantages and some limitations:

- Resolution and Detail: SLA printers provide much higher resolution and finer detail compared to FDM, making them ideal for highly detailed parts.

- Surface Finish: Parts produced through SLA have a smoother surface finish compared to FDM, reducing the need for post-processing.

- Material Properties: SLA resins are capable of exhibiting properties similar to engineering plastics, which make them suitable for both prototyping and functional parts.

However, SLA printing has its downsides, such as longer print times, higher material costs, and the need for support structures for complex designs.

The SLA 3D Printing Process

The SLA process can be broken down into several key stages:

Step-by-Step Explanation

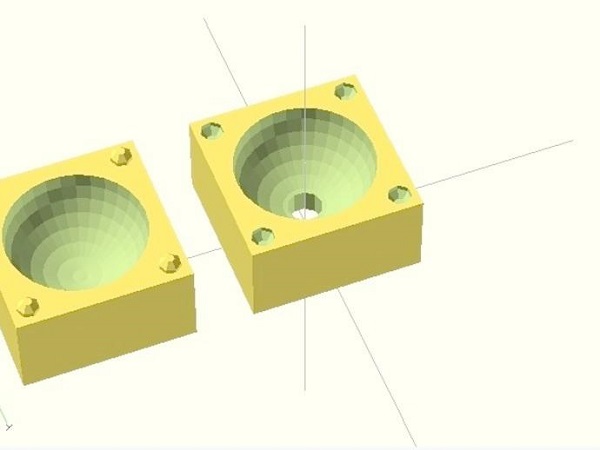

- Design Preparation: The first step involves creating a 3D model using Computer-Aided Design (CAD) software. This model is sliced into thin layers, and a toolpath file is generated to guide the printer.

- Resin Preparation: Photopolymer resin is poured into the resin vat of the SLA printer. The resin is sensitive to UV light and begins to cure when exposed.

- Build Platform Preparation: A build platform is set just below the surface of the resin, often coated with a release agent to prevent the object from sticking.

- Layer-by-Layer Curing: The UV laser or projector solidifies the resin layer by layer according to the toolpath file. After each layer is cured, the build platform moves slightly downward to accommodate the next layer.

- Support Structure Removal: Support structures are removed after printing, and the part is cleaned to eliminate uncured resin residue.

- Post-Processing: Depending on the application, the printed object may undergo additional post-processing steps like sanding, polishing, or coating to achieve the desired finish.

Materials Used: Resins and Their Properties

The choice of resin plays a significant role in the properties of the printed object. Some common types of resins used in SLA include:

- Standard Resins: General-purpose materials suitable for a variety of applications, offering good strength and flexibility.

- Engineering Resins: Designed for high mechanical strength, these resins are used for functional prototypes and end-use parts.

- Medical-Grade Resins: These biocompatible materials are intended for medical and dental applications, ensuring safety for human use.

- Castable Resins: These resins are developed for mold making and metal casting, useful for jewelry design and similar applications.

Each resin type has specific properties that make it suitable for various industries and applications.

Advantages and Limitations

Precision and Detail

One of the key advantages of SLA 3D printing is its ability to produce highly detailed and precise parts. The layer thickness can be as small as 0.025 mm, enabling the production of intricate geometries that are often not possible with other 3D printing methods. This makes SLA ideal for applications in fields like medical device manufacturing, where high precision is critical.

Speed and Cost Efficiency

While SLA is generally slower than processes like FDM, it provides a balance between print quality and speed. The print time depends on factors such as model complexity, layer height, and the curing time for each layer. Despite the longer printing times, SLA’s high quality and reduced need for post-processing can make it cost-efficient in the long term, especially for detailed prototypes and small production runs.

Limitations and Challenges

Despite its many advantages, SLA also has limitations:

- Material Costs: Photopolymer resins are more expensive than the thermoplastic filaments used in FDM, making SLA a costlier option for larger production runs.

- Support Structures: Complex models often require support structures during the print process, which must be removed afterward. This can add additional time and labor to the overall production process.

- UV Safety: Handling UV light and resins requires safety precautions to protect workers from harmful UV radiation and exposure to the chemicals in the resin.

Applications of SLA 3D Printing

SLA 3D printing has broad applications across various industries. Let's explore some key sectors that benefit from this technology.

Industrial and Manufacturing Uses

In industrial manufacturing, SLA is used for both rapid prototyping and low-volume production of parts. It allows for the fast iteration of designs and the creation of functional prototypes with tight tolerances. The aerospace and automotive industries, in particular, benefit from SLA's ability to produce lightweight, strong components and reduce development times.

Medical and Dental Applications

SLA 3D printing has become a game-changer in the medical and dental fields due to its ability to create custom, patient-specific devices. From anatomical models and surgical guides to custom prosthetics and dental implants, SLA enables healthcare professionals to deliver more personalized and precise treatments. The biocompatibility of certain resins makes SLA suitable for medical applications.

Art, Design, and Jewelry Creation

Artists and designers use SLA to create complex and intricate pieces that would be difficult to produce using traditional manufacturing methods. In jewelry design, for example, SLA allows for the rapid production of detailed prototypes or even final pieces. The precision and detail achievable with SLA have made it a favored technology in the creative industries, including sculpture, conceptual art, and more.

Conclusion

Stereolithography 3D printing has transformed modern manufacturing, design, and prototyping, offering unmatched precision and detail. While it faces challenges such as material costs and the need for support structures, its benefits—especially in producing high-quality, complex parts—have made it indispensable in industries ranging from medical to automotive to art. As the technology continues to evolve, SLA is poised to play an increasingly important role in shaping the future of product development and innovation.