Introduction to Selective Laser Melting

Selective Laser Melting (SLM) is a revolutionary 3D printing or additive manufacturing technology that enables the creation of complex, high-performance metal parts. By using a powerful laser to melt metal powders and fuse them together layer by layer, SLM can produce parts with intricate geometries that would be difficult or impossible to achieve with traditional manufacturing methods. This process is increasingly used in industries such as aerospace, automotive, medical, and tooling, where the demand for lightweight, strong, and highly customized components is growing.

Definition and Overview

Selective Laser Melting (SLM) is a type of additive manufacturing that uses a focused laser beam to melt and fuse metal powder particles. The process builds up parts layer by layer from a 3D digital model created in Computer-Aided Design (CAD) software. Unlike traditional subtractive manufacturing methods, which involve removing material from a solid block, SLM adds material one layer at a time, making it suitable for creating complex shapes, internal structures, and intricate details.

The SLM process starts with a digital 3D model, which is sliced into thin cross-sectional layers. The machine then uses a high-powered laser to selectively melt the metal powder on each layer according to the model's design. After one layer is completed, the build platform is lowered, and a new layer of metal powder is spread over the previous layer. This process repeats until the final part is built.

Historical Development

The concept of laser-based metal processing has existed since the 1980s, but Selective Laser Melting itself was developed more recently, in the 1990s. Early advancements in laser technology and computer control systems laid the groundwork for modern SLM machines. By the early 2000s, commercial SLM systems were available, and the technology began to gain widespread adoption, particularly in high-tech sectors that required high-precision, high-performance parts.

Continuous improvements in lasers, material formulations, and software have enhanced the precision, speed, and material options for SLM, making it a versatile manufacturing technique for producing high-quality, customized components.

How SLM Works

Laser Technology and Materials

The heart of the SLM process is a high-powered laser that melts metal powder particles to create a solid layer. The laser is typically a fiber laser or CO2 laser, which can generate high temperatures capable of melting metals like titanium, stainless steel, aluminum, cobalt-chrome, and more. The metal powder used in SLM must be carefully chosen based on its mechanical properties and compatibility with the laser.

Some of the most commonly used materials in SLM include:

- Titanium alloys: Known for their strength-to-weight ratio, commonly used in aerospace and medical implants.

- Stainless steel: Offers durability and resistance to corrosion, often used in tooling and automotive parts.

- Aluminum alloys: Lightweight and versatile, suitable for aerospace and automotive industries.

- Cobalt-chrome: Used in medical devices, particularly for parts that must withstand high stress.

Layer-by-Layer Construction

The process of SLM follows a precise, layer-by-layer approach to build a part:

- Powder Bed Preparation: A thin layer of metal powder is evenly spread across the build platform. This powder is usually supplied from a hopper and distributed by a recoater blade.

- Laser Scanning: The laser scans the powder bed, melting the metal powder according to the cross-sectional pattern defined by the digital 3D model. The laser energy causes the powder particles to fuse together, solidifying into a layer of the part.

- Platform Lowering: Once the first layer is complete, the build platform lowers by a small increment, typically around 20 to 50 microns, and a new layer of powder is spread over the previous one.

- Repetition: The process is repeated layer by layer, with each layer solidifying as the laser fuses the powder. Over time, the part is built up, from the bottom to the top, until the final part is completed.

- Post-Processing: Once the part is finished, post-processing steps such as heat treatment, surface polishing, and support removal are often required to improve mechanical properties and finish.

Applications of SLM

Aerospace Industry

SLM is widely used in aerospace for the production of complex parts such as:

- Turbine blades: These are often designed with intricate internal cooling channels that would be difficult to machine. SLM's ability to produce geometries with internal cavities provides a major advantage.

- Engine components: Lightweight, high-strength parts like brackets, nozzles, and structural elements benefit from the material efficiency and precision of SLM.

- Custom parts: SLM enables rapid prototyping and low-volume production of customized parts, which is crucial in the aerospace industry for ensuring optimal performance.

Automotive Sector

In the automotive industry, SLM is used for:

- Engine components: Components such as exhaust manifolds, cylinder heads, and turbochargers benefit from the weight reduction and enhanced performance enabled by SLM.

- Gears and housings: The ability to produce lightweight, complex parts improves the performance and fuel efficiency of vehicles.

- Prototyping and customization: SLM allows for rapid prototyping of new designs, enabling quicker innovation cycles and the ability to create custom parts for high-performance or luxury vehicles.

Medical Field

In the medical industry, SLM is used to produce:

- Custom implants and prosthetics: Personalized parts that fit a patient's unique anatomy can be designed and manufactured using SLM. These can include hip implants, dental crowns, and cranial implants.

- Surgical tools: The precision and customization capabilities of SLM enable the creation of highly specialized surgical instruments.

- Biocompatible materials: SLM can use materials that are biocompatible and allow for safe integration with the human body.

Advantages of SLM

Precision and Complexity

SLM excels in producing parts with high precision and the ability to create complex geometries. The layer-by-layer construction allows for detailed features like fine lattice structures, internal channels, and undercuts that traditional manufacturing methods (like machining or casting) cannot achieve. This is particularly valuable in industries such as aerospace and medical, where parts must meet exacting tolerances.

Material Efficiency

SLM is a material-efficient process. Unlike subtractive methods, which cut away material from a solid block and create significant waste, SLM only uses the material needed for the part. Unused metal powder can be recycled and reused, making it an environmentally friendly and cost-effective option for producing parts.

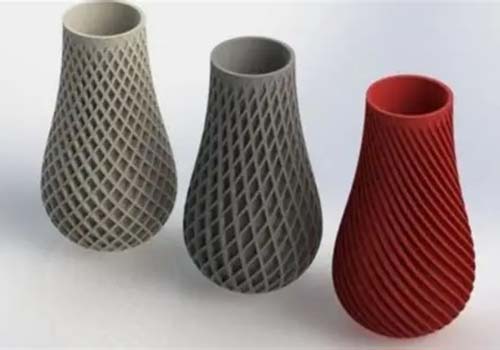

Design Freedom

One of the most significant benefits of SLM is the design freedom it provides. Engineers and designers can create parts with organic shapes, internal structures, and complex features that would be challenging or impossible with traditional methods. This flexibility enables innovations that improve performance, reduce weight, and enhance functionality.

Challenges and Limitations

Cost and Accessibility

Despite its advantages, SLM can be costly due to:

- High equipment costs: The machines themselves can be expensive, as are the specialized materials required for the process.

- Material costs: Metal powders used in SLM are often more expensive than traditional metals.

- Operational costs: The high energy consumption of the laser and maintenance of the machines also contribute to the overall expense.

These costs may be prohibitive for smaller businesses or companies that do not require high-volume production. However, with advancements in technology and increased adoption, costs are expected to decrease over time.

Post-Processing

SLM parts often require post-processing to achieve the desired surface finish and mechanical properties. This can include:

- Heat treatment to relieve residual stresses and improve material strength.

- Machining to improve surface finish or precision on certain areas.

- Polishing and finishing for cosmetic improvements.

While these post-processing steps can enhance the final product, they also add to the overall cost and production time.

Material Properties

Not all materials are suitable for the SLM process, and the properties of materials used in SLM can differ from those produced through traditional methods like casting or forging. Some metals may exhibit different strength, ductility, or fatigue resistance when processed with SLM, which requires thorough testing and validation for each specific application.

FAQ

1. What are the primary benefits of Selective Laser Melting (SLM)?

SLM offers several key advantages, including high precision, the ability to create complex geometries, and material efficiency. The technology also enables the use of lightweight materials for better performance, customization, and rapid prototyping, making it highly valuable in industries such as aerospace, automotive, and medical.

2. What are common applications of SLM in different industries?

SLM is used for:

- Aerospace: Manufacturing of turbine blades, engine parts, and structural components.

- Automotive: Production of high-performance engine parts, gears, and exhaust systems.

- Medical: Custom implants, prosthetics, and surgical tools.

3. What are the challenges associated with Selective Laser Melting (SLM)?

Some of the main challenges include:

- High costs for equipment, materials, and maintenance.

- Post-processing requirements to achieve the desired finish and material properties.

- Material properties that may differ from traditional methods, requiring careful consideration for specific applications.

SLM represents a powerful tool for manufacturing complex, high-performance parts, though it requires careful consideration of its costs and post-processing needs.