Introduction to 3D Printing

3D printing, also known as additive manufacturing, is a revolutionary technology that has radically changed the landscape of manufacturing. Unlike traditional methods, where parts are created by cutting away material from a solid block, 3D printing builds objects layer by layer directly from a digital model. This method enables the production of intricate designs, custom parts, and highly complex geometries that were previously impractical or prohibitively expensive to produce. As 3D printing continues to mature, companies specializing in this technology are redefining how products are designed, developed, and brought to market, leading to transformative changes in various industries.

Types of 3D Printing Technologies

The world of 3D printing is vast and diverse, with several technologies available, each offering unique advantages depending on the application. Here are some of the most prominent 3D printing techniques:

Fused Deposition Modeling (FDM)

FDM is the most commonly used 3D printing technology. It works by extruding thermoplastic filament through a heated nozzle, which is then deposited in layers to form a solid part. The material cools and solidifies quickly after being laid down, allowing for efficient printing. FDM is known for its affordability, making it ideal for hobbyists and small businesses. However, while it is cost-effective, the finish often requires additional post-processing to achieve a smooth, professional look.

Stereolithography (SLA)

SLA uses ultraviolet (UV) lasers to cure liquid photopolymer resin layer by layer. The laser selectively hardens the resin based on the digital model, creating high-precision parts. This technology is particularly popular for applications requiring fine details and smooth finishes, such as in jewelry and dental prosthetics. SLA is known for its high resolution but can be slower than FDM for large prints.

Selective Laser Sintering (SLS)

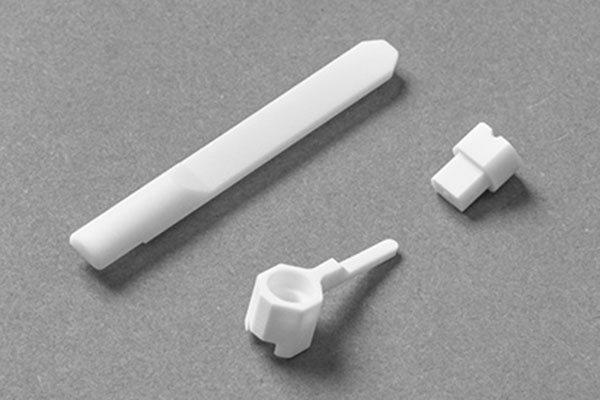

SLS uses a laser to sinter (fuse) powdered material, typically nylon, into solid parts. Unlike FDM and SLA, SLS does not require support structures because the surrounding powder acts as a support for overhangs and complex geometries. SLS is widely used in aerospace, automotive, and industrial applications, as it produces strong, durable parts suitable for functional testing or low-volume production.

Key Players in the 3D Printing Industry

Several companies have become leaders in the 3D printing sector, contributing to its widespread adoption and continuous advancement:

- Stratasys: A pioneer in the FDM and PolyJet printing technologies, Stratasys offers a wide range of 3D printers and materials, enabling high-quality prototyping and manufacturing.

- 3D Systems: Known for its extensive work in SLA and SLS, 3D Systems provides solutions for a variety of industries, including aerospace, automotive, and healthcare.

- Desktop Metal: Specializing in metal 3D printing, Desktop Metal has developed innovative technologies like binder jetting and melted powder deposition, enabling mass production of metal parts.

- Formlabs: A major player in the SLA space, Formlabs is known for offering high-quality 3D printers at an accessible price, making it a favorite among engineers, designers, and dentists.

Applications of 3D Printing

The versatility of 3D printing has opened up new possibilities across a broad range of industries. Below are some key sectors benefiting from this transformative technology:

Aerospace

3D printing in the aerospace industry is particularly valuable for manufacturing lightweight, complex parts that contribute to improved performance and reduced fuel consumption. Leading companies like GE Aviation and Boeing use 3D printing to produce engine components, structural parts, and custom tools. The technology allows them to design parts with optimized shapes, reducing material waste and weight while maintaining strength.

Medical and Dental

The medical field is one of the most significant beneficiaries of 3D printing. The technology is used to create custom prosthetics, implants, and orthopedic devices tailored to an individual's anatomy. In dental practices, 3D printing enables the creation of precise molds for crowns, bridges, and other dental appliances, improving fit, comfort, and turnaround time for patients.

Bioprinting—the process of printing biological tissues—is also advancing rapidly, opening up possibilities for the development of artificial organs and tissue regeneration.

Automotive

3D printing is revolutionizing the automotive industry by enabling manufacturers to prototype parts quickly, design customized components, and produce low-volume parts with reduced lead times. Companies like Ford and Ferrari use 3D printing for everything from engine components to tooling. The ability to quickly iterate designs leads to faster innovation cycles and reduced production costs.

Consumer Goods

In the consumer goods industry, 3D printing is enabling mass customization of products. Companies in fashion, footwear, eyewear, and home decor are using 3D printing to create personalized products. For instance, brands like Adidas are utilizing 3D printing to manufacture custom shoes tailored to individual foot shapes, while eyewear companies are producing personalized frames.

Benefits of 3D Printing in Manufacturing

The widespread adoption of 3D printing in manufacturing brings a host of benefits that traditional methods cannot offer. Here are some of the key advantages:

Cost Efficiency

3D printing significantly reduces production costs by eliminating the need for expensive tooling and molds. This is particularly advantageous for short-run production or on-demand manufacturing, where low quantities of customized parts are needed. Additionally, because the material is deposited layer by layer, there is much less material waste compared to traditional subtractive methods.

Customization and Personalization

One of the most powerful advantages of 3D printing is its ability to create customized and personalized products with ease. In industries like healthcare and fashion, the ability to tailor products to specific needs—whether it’s a custom prosthetic limb or a unique pair of shoes—allows companies to better meet customer demands and differentiate their offerings.

Reduced Lead Times

Traditional manufacturing processes often require lengthy setup times, tool changes, and production cycles. 3D printing, on the other hand, allows for rapid prototyping and the quick production of final parts. This leads to dramatically shortened lead times from concept to production, which is crucial for industries where time-to-market is a competitive advantage.

Complexity at No Extra Cost

Unlike traditional manufacturing, which can become exponentially more expensive with increased complexity, 3D printing allows for intricate designs without significantly increasing production costs. Complex geometries—like internal channels or organic shapes—can be produced easily, making it ideal for industries like aerospace, where performance optimization is crucial.

On-Demand and Localized Production

3D printing enables on-demand manufacturing, reducing the need for large inventories and complex supply chains. Companies can produce parts as needed, minimizing storage costs and the risk of overproduction. This capability also supports localized production, allowing companies to produce parts closer to where they are needed, reducing shipping costs and delivery times.

Conclusion: The Impact of 3D Printing on Traditional Manufacturing

The emergence of 3D printing manufacturing companies is reshaping traditional manufacturing paradigms. By leveraging additive technologies, these companies are breaking through the constraints of conventional manufacturing methods, offering greater flexibility, customization, and efficiency. Industries such as aerospace, healthcare, automotive, and consumer goods are all experiencing profound changes in how products are designed and produced. As 3D printing technology continues to evolve, its impact on traditional manufacturing will expand, driving further innovation and creating new possibilities for businesses and consumers alike.

FAQ

- What are the main advantages of 3D printing over traditional manufacturing methods?

- 3D printing offers cost efficiency, reduced material waste, and the ability to produce complex geometries. It also allows for rapid prototyping, shortened lead times, and customization of products, making it an ideal solution for industries like aerospace, healthcare, and consumer goods.

- Which industries benefit the most from 3D printing technology?

- Industries like aerospace, automotive, healthcare, and consumer goods are benefiting significantly from 3D printing. It allows for rapid prototyping, lightweight component manufacturing, customized solutions, and lower production costs.

- How does 3D printing contribute to sustainable manufacturing practices?

- 3D printing contributes to sustainability by reducing material waste and optimizing resource usage. It also supports on-demand manufacturing, reducing the need for large inventories and minimizing the energy consumption associated with transportation and storage. The use of recycled materials in some 3D printing processes further enhances sustainability.