Selective Laser Melting (SLM), also known as Laser Powder Bed Fusion (LPBF), is at the forefront of metal 3D printing, revolutionizing the manufacturing sector by enabling the production of intricate, high-performance metal parts that were previously difficult or impossible to create using traditional methods. This advanced additive manufacturing technology employs a high-powered laser to melt and fuse metal powders layer by layer, offering unmatched precision, material efficiency, and design complexity. In this article, we’ll explore the principles, history, advantages, applications, challenges, and future potential of SLM technology.

Introduction to SLM Metal 3D Printing

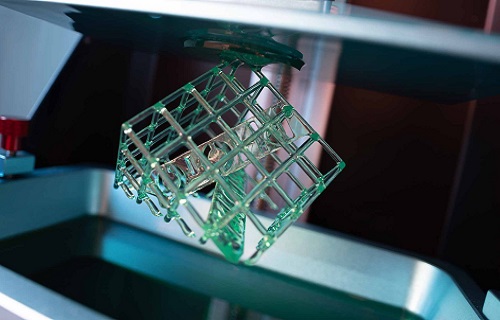

SLM technology has fundamentally altered how industries approach metal part manufacturing. By using a focused laser beam to melt metal powder particles and build parts layer by layer, SLM enables the creation of geometries and features that are otherwise impractical with conventional methods. These include complex internal structures, lightweight designs, and parts with optimal strength-to-weight ratios. As a result, SLM has found applications across aerospace, automotive, medical, and other high-performance industries, making it a key enabler of innovation in manufacturing.

Definition and Principles

What is Selective Laser Melting (SLM)?

SLM is an additive manufacturing process that uses a high-powered laser to selectively melt metal powder, fusing it together to build a solid 3D part. Unlike traditional subtractive methods, which involve carving out material from a solid block, SLM builds the part incrementally, one layer at a time. This allows for the production of highly complex parts with exceptional strength, material efficiency, and flexibility in design.

How Does SLM Work?

- Preparation: The process begins with the creation of a 3D model of the part using computer-aided design (CAD) software. The model is then sliced into thin layers using specialized software, which translates the design into a set of instructions for the printer.

- Powder Deposition: A thin layer of metal powder is spread evenly over the build platform. The powder layer is typically 20 to 100 microns thick, depending on the resolution and desired properties.

- Laser Melting: A focused laser beam scans the surface of the powder bed, selectively melting and fusing the powder particles based on the cross-sectional data from the CAD model. The laser fuses the metal particles to form a solid layer, while the surrounding powder remains unmolten, providing support for the part.

- Layer Repetition: Once a layer is completed, the platform lowers slightly, and a new layer of metal powder is spread over the previous layer. This process repeats until the entire part is built.

- Cooling and Removal: After the part is fully built, it is allowed to cool and solidify. Excess powder is then removed, and the part undergoes post-processing steps, such as support removal, surface finishing, and heat treatment.

Historical Development

Evolution of SLM Technology

SLM technology has evolved significantly since its inception. The concept of using lasers to fuse metal powder began in the early 1990s, and the first commercial SLM systems were introduced in the late 1990s. These early systems were mainly used for rapid prototyping and small-scale production. Over time, improvements in laser technology, machine precision, and material science expanded the capabilities of SLM, allowing it to produce high-performance parts for demanding industries such as aerospace and healthcare.

Milestones in SLM Technology

- 1990s: Introduction of the first commercial SLM machines, focused primarily on prototyping.

- 2000s: Adoption of SLM in aerospace, automotive, and medical sectors, driven by demand for high-performance, lightweight parts.

- 2010s: Significant advancements in machine speed, material variety, and post-processing techniques, expanding the applications of SLM.

- Present: Ongoing innovations, including multi-laser systems, real-time process monitoring, and AI-driven optimization, continue to enhance the capabilities and cost-effectiveness of SLM.

Advantages of SLM Technology

Material Efficiency

One of the most notable advantages of SLM is its material efficiency. Unlike subtractive manufacturing, where large amounts of material are wasted during the cutting or milling process, SLM only uses the exact amount of material needed to build each part. Additionally, unused metal powder can be recycled and reused in future builds, significantly reducing material costs and environmental impact.

Mechanical Properties

SLM-produced parts exhibit excellent mechanical properties, including high strength, durability, and resistance to fatigue. This is due to the fine-grain microstructure achieved through the rapid cooling of molten metal during the laser melting process. The density of parts produced by SLM is typically much higher than those made by traditional powder metallurgy techniques, leading to superior mechanical performance.

Complexity of Designs

SLM enables the creation of highly complex and intricate designs that would be difficult, if not impossible, to achieve using traditional manufacturing methods. This includes:

- Internal geometries: Features like cooling channels, lattice structures, and internal voids that optimize the part’s performance or functionality.

- Conformal cooling: Cooling channels that follow the shape of the part, improving heat dissipation and reducing the need for post-processing.

- Lightweight structures: Optimization of material use to reduce weight without compromising strength, which is especially beneficial in industries like aerospace and automotive.

Applications of SLM in Various Industries

Aerospace

In aerospace, SLM is used to produce parts that require high strength-to-weight ratios and resistance to extreme temperatures and stresses. Typical parts include turbine blades, engine components, and lightweight structural elements. The ability to integrate complex internal features, such as cooling channels, into these parts has led to improved performance and fuel efficiency for aircraft and spacecraft.

Automotive

SLM has revolutionized automotive manufacturing by enabling faster prototyping, custom tooling, and the production of lightweight, high-performance parts. Components such as gears, brackets, suspension parts, and exhaust manifolds can now be produced with optimized designs that reduce weight and improve strength. SLM also helps reduce lead times, allowing manufacturers to bring new products to market faster.

Medical

In the medical field, SLM is widely used to create custom implants, prosthetics, and surgical instruments. The technology's precision and flexibility allow for the production of patient-specific solutions, such as implants tailored to the exact shape of an individual’s anatomy. SLM also supports the creation of porous structures that encourage bone growth, improving the integration of implants.

Challenges and Limitations

Cost and Accessibility

Despite its many benefits, SLM technology remains relatively expensive. The high cost of equipment, metal powders, and maintenance can be prohibitive, especially for small and medium-sized businesses. Additionally, the complexity of operating SLM machines requires specialized training and expertise, further adding to the cost.

Material Constraints

While SLM supports a wide range of metal powders, including titanium, stainless steel, aluminum, and cobalt-chrome alloys, not all materials are suitable for this process. Some metals require specialized handling, pre-alloying, or post-processing to achieve the desired properties. Ongoing research aims to expand the material compatibility of SLM and optimize processing techniques for various metals.

Post-Processing Requirements

SLM parts often require significant post-processing, including support removal, heat treatment, and surface finishing. These additional steps add time and cost to the overall production process. However, they are essential for ensuring that the final part meets the required mechanical properties, dimensional accuracy, and surface finish standards.

FAQs

What types of materials can be used in SLM?

SLM supports a variety of metals, including titanium, stainless steel, aluminum, cobalt-chrome alloys, and nickel-based superalloys. Each material offers unique properties, making them suitable for specific applications, such as biocompatibility for medical implants or heat resistance for aerospace components.

How does SLM compare to other metal 3D printing technologies?

Compared to other metal 3D printing technologies like Direct Metal Laser Sintering (DMLS) or Electron Beam Melting (EBM), SLM offers higher part density and superior mechanical properties. SLM also provides greater flexibility in design and a smoother surface finish, making it ideal for producing functional parts with complex geometries.

What are the main post-processing steps after SLM printing?

Post-processing steps for SLM parts typically include support removal, heat treatment (such as stress relieving or annealing), machining for dimensional accuracy, and surface finishing, such as polishing or coating. These steps are critical for achieving the desired performance, durability, and aesthetics of the final part.

Conclusion

SLM technology has revolutionized metal 3D printing by enabling the production of complex, high-performance parts that traditional manufacturing methods could not achieve. Its material efficiency, superior mechanical properties, and design flexibility have made it a game-changer in industries like aerospace, automotive, and healthcare. Although challenges such as cost and material limitations remain, ongoing advancements in technology and research are expected to further enhance the capabilities and accessibility of SLM, paving the way for broader adoption in the future. As SLM continues to evolve, its potential to reshape modern manufacturing practices is enormous, unlocking new possibilities for innovation and customization.