Introduction to SLM 3D Printing

Selective Laser Melting (SLM) 3D printing has emerged as a transformative force in the manufacturing sector. This advanced additive manufacturing technology allows for the creation of high-performance metal parts through a layer-by-layer fusion process, using a focused laser to melt metal powders. Unlike traditional manufacturing methods, which often involve subtracting material from a larger piece, SLM builds components from the ground up, offering substantial benefits in design flexibility, material efficiency, and production speed. The precision and complexity of parts that can be achieved with SLM are helping to revolutionize industries such as aerospace, automotive, and medical.

Definition and Principles

What is SLM 3D Printing?

Selective Laser Melting (SLM) is a form of additive manufacturing that uses a laser to melt and fuse metal powder particles together, based on a 3D digital model. The process builds up the part layer by layer, allowing for the production of highly complex and intricate geometries that would be impossible or prohibitively expensive with traditional subtractive manufacturing methods.

How Does It Work?

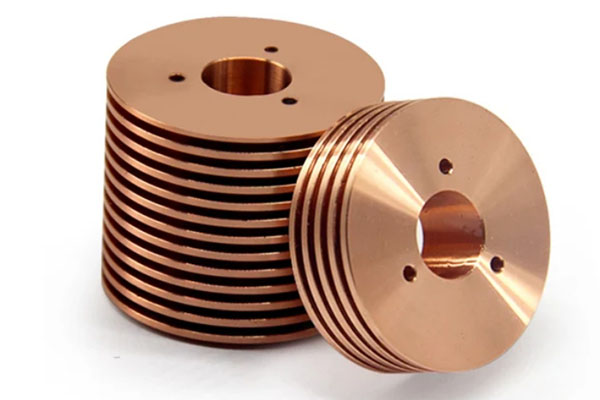

- Preparation: A thin layer of metal powder, usually between 20 to 100 microns thick, is spread evenly over the build platform using a recoater blade.

- Melting: A high-powered laser scans the surface of the powder bed, selectively melting the powder particles along the contours of the first layer, as defined by the 3D model. As the powder melts, it fuses into a solid metal structure.

- Layer-by-Layer Construction: After the laser has melted the first layer, the build platform lowers slightly, and a new layer of metal powder is applied on top. This process repeats, building up the part one layer at a time until the object is fully formed.

- Finishing: Once the part is printed, excess powder is removed, and post-processing steps such as heat treatment, machining, or surface finishing may be applied to improve the part’s properties and appearance.

Advantages Over Traditional Manufacturing

Design Complexity and Precision

SLM 3D printing stands out for its ability to produce highly complex and intricate geometries that traditional manufacturing methods simply cannot achieve. Through additive manufacturing, parts can incorporate features such as internal cooling channels, lattice structures, and undercuts—designs that would typically require multiple components or be impossible to fabricate with conventional techniques. This capability is particularly beneficial for industries requiring high-performance parts, such as aerospace, where part optimization for lightweight, strength, and aerodynamics is critical.

Material Efficiency

One of the standout advantages of SLM over traditional manufacturing is its material efficiency. Traditional methods, like CNC machining, often result in significant material waste, as large metal blocks are cut down to shape. SLM, however, only uses the metal powder required to build the part, significantly reducing scrap material. This is not only more cost-effective but also more sustainable, as less raw material is wasted in the process.

Speed of Prototyping

The ability to rapidly produce prototypes is another major advantage of SLM 3D printing. Designers can quickly iterate on designs, producing prototypes and conducting tests without the need for expensive tooling or molds. This dramatically shortens development cycles, enabling quicker product launches, faster response to market changes, and the ability to test new concepts in real-world conditions more efficiently.

Applications of SLM 3D Printing

Aerospace Industry

The aerospace industry has been an early adopter of SLM 3D printing, benefiting from its ability to produce lightweight, high-strength components that are optimized for performance and fuel efficiency. SLM is used to create components such as:

- Turbine blades that feature internal cooling channels, optimizing thermal performance and improving engine efficiency.

- Structural components and brackets that are lighter but just as strong, contributing to reduced aircraft weight and fuel consumption.

- Customization for low-volume or highly specialized parts that are difficult or expensive to manufacture with traditional methods.

Automotive Sector

In the automotive industry, SLM 3D printing is used for creating both functional parts and prototypes. The technology enables manufacturers to produce lightweight, durable, and customized components, such as:

- Engine parts, exhaust systems, and brackets, which benefit from SLM’s ability to optimize design for strength and weight reduction.

- Low-volume production of specialized parts for luxury cars, sports cars, and electric vehicles, where customization and high performance are paramount.

- Rapid prototyping of new designs allows for faster testing, iteration, and implementation of new features.

Medical Field

SLM 3D printing is revolutionizing the medical industry by enabling the production of customized and patient-specific implants, prosthetics, and surgical tools. Its advantages in medical applications include:

- Personalized implants such as hip and knee replacements, which can be tailored to the unique anatomy of each patient, ensuring a better fit and reducing recovery time.

- Surgical tools and custom prosthetics, which can be precisely designed to meet individual patient needs, improving the functionality and comfort of these devices.

- Biocompatibility, with materials like titanium and stainless steel, making it suitable for implantable devices and medical instruments.

Benefits of SLM 3D Printing

Design Complexity and Precision

SLM 3D printing offers a level of design freedom that traditional manufacturing methods cannot match. It allows for the creation of parts with intricate geometries, including hollow structures, complex lattice patterns, and conformal cooling channels. These features help improve performance, reduce material usage, and enable designs that optimize both strength and weight.

Material Efficiency

SLM’s layer-by-layer manufacturing process uses only the material needed to form the final product, minimizing waste. This contrasts sharply with traditional subtractive manufacturing methods, where material is often removed from large billets, leading to significant material loss. The ability to utilize high-precision metal powders also supports sustainable manufacturing practices by reducing scrap material and energy consumption.

Speed of Prototyping

The speed at which SLM can produce functional prototypes is a significant benefit. Designers and engineers can test new ideas, make adjustments, and validate performance before committing to expensive tooling or mass production. This agility in product development allows companies to bring new products to market faster and respond more efficiently to market demands or changes in customer requirements.

Future Outlook of SLM 3D Printing

Technological Advancements

The future of SLM 3D printing is exciting, with continuous advancements in several key areas:

- Laser technology improvements for faster, more accurate melting and fusing of powder particles.

- Better powder handling systems, which can increase the efficiency of powder deposition and reduce contamination.

- Enhanced process control for better consistency and higher-quality parts with fewer defects.

- Material development to expand the range of metals and alloys that can be used in SLM, broadening its applications even further.

Market Growth Projections

The global market for SLM 3D printing is expected to grow at a rapid pace. As industries continue to recognize its benefits—such as customization, material efficiency, and speed—demand for SLM systems and services is expected to increase. Market analysts predict strong growth in sectors such as aerospace, automotive, medical, and consumer goods.

Potential New Applications

Looking ahead, SLM 3D printing could be applied in a variety of new and emerging sectors:

- Consumer electronics, where customized, lightweight components could enhance product functionality and design.

- Energy production, particularly in the creation of high-performance turbine blades for gas and wind power plants.

- Regenerative medicine, where SLM could play a role in bioprinting tissues or scaffolds for cell growth and organ repair.

FAQs

What materials can be used in SLM 3D printing?

SLM 3D printing supports a wide range of metal materials, including:

- Stainless steel: Excellent for strength, durability, and corrosion resistance.

- Titanium: Known for its high strength-to-weight ratio and biocompatibility.

- Aluminum: Lightweight and thermally conductive, often used in aerospace and automotive applications.

- Cobalt-chrome: Often used in medical implants due to its wear resistance.

- Nickel alloys: Used in high-temperature environments, such as aerospace engines.

Is SLM 3D printing cost-effective for mass production?

SLM 3D printing is more cost-effective for small to medium-sized production runs or highly customized parts. The high cost of equipment, materials, and post-processing steps means it’s not always the most economical choice for mass production. However, for parts with complex geometries or low-volume requirements, SLM can be more cost-effective than traditional methods, which require expensive molds or tooling.

How does SLM 3D printing contribute to sustainability?

SLM 3D printing contributes to sustainability in several ways:

- Reduced material waste: Only the material needed to build the part is used, minimizing waste.

- Energy efficiency: By producing parts in fewer steps and with less material waste, SLM reduces energy consumption compared to traditional manufacturing methods.

- Optimized designs: The ability to create lightweight, efficient designs helps reduce the environmental impact, especially in industries like aerospace and automotive where weight reduction can lead to lower fuel consumption and emissions.