How Does 3D Print and Ship Work?

3D Printing Process

3D printing, also known as additive manufacturing, is a revolutionary technology that creates three - dimensional objects from a digital model. The process starts with a 3D model, which can be created using computer - aided design (CAD) software, 3D scanning, or even downloaded from online repositories.

The first crucial step is slicing. Specialized slicing software takes the 3D model and divides it into numerous thin horizontal layers. Each layer represents a cross - section of the final object. For example, if you are printing a small figurine, the slicing software will create hundreds or even thousands of layers, depending on the size and complexity of the model. The thickness of these layers typically ranges from 0.1mm to 0.3mm for consumer - grade 3D printers, while industrial printers can achieve much thinner layers, down to 0.01mm or less, resulting in higher - quality prints.

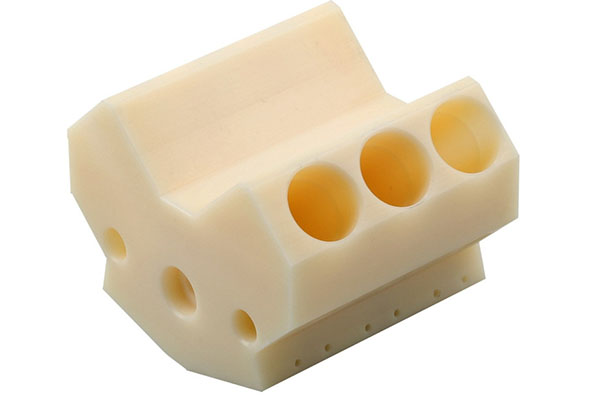

There are several 3D printing technologies, with Fused Deposition Modeling (FDM) and Stereolithography (SLA) being two of the most common. In FDM, the printer uses a spool of thermoplastic filament, such as PLA (polylactic acid) or ABS (acrylonitrile butadiene styrene). The filament is fed into a heated extruder, where it is melted. The extruder then moves in the X, Y, and Z axes according to the instructions from the sliced model. As it moves, it deposits the melted plastic in a precise pattern, layer by layer. Each layer bonds with the previous one as the plastic cools and solidifies. This process is similar to how a hot - glue gun works, but with much more precision.

SLA, on the other hand, is a more precise and often used for high - detail prints. It uses a vat of liquid photopolymer resin. A high - power ultraviolet (UV) laser is directed by a computer - controlled mirror system. The laser traces the shape of each layer onto the surface of the liquid resin. When the UV laser hits the resin, it causes a chemical reaction, curing the resin and turning it into a solid plastic. After each layer is cured, the build platform is lowered slightly, and a new layer of resin is spread over the previously cured layer. This process continues until the entire 3D object is complete. SLA can produce parts with much finer details and smoother surfaces compared to FDM, making it ideal for applications such as jewelry design, dental models, and high - end prototyping.

Shipping Process

Once the 3D printing process is complete, the printed object enters the shipping phase. The first task is to carefully remove the object from the 3D printer. If the print had any support structures (which are often necessary for complex geometries, especially in FDM and SLA printing), these need to be removed. In FDM prints, support structures can sometimes be easily snapped off, while in SLA prints, they may require more delicate handling, such as using pliers or a sharp tool to carefully cut them away without damaging the main part.

After removing the supports, the object may need some post - processing. This could include sanding to smooth the surface, painting for aesthetic purposes, or applying a sealant to protect the material. Once the post - processing is done, it's time to package the item for shipping.

Choosing the right packaging materials is crucial. For small and lightweight 3D - printed items, a simple cardboard box with bubble wrap or packing peanuts can provide sufficient protection. However, for larger or more fragile prints, more robust packaging may be required. For example, if you have printed a large, hollow 3D - printed sculpture, it may need to be placed in a custom - made foam insert inside a sturdy corrugated box. This foam insert will cradle the object and absorb any impacts during transit.

Once the item is properly packaged, it's handed over to a shipping carrier. Popular shipping carriers include FedEx, UPS, DHL, and the United States Postal Service (USPS) in the US. The choice of carrier depends on several factors, such as the destination, the size and weight of the package, the shipping speed required, and the cost. For international shipments, additional considerations may include customs regulations and duties.

The shipping carrier then takes over, scanning the package into their system and providing tracking information. The package travels through their network of sorting facilities and transportation vehicles (trucks, planes, ships, etc.). Eventually, it reaches the destination address, where it is delivered to the customer. The entire shipping process can take anywhere from 1 - 2 days for domestic express shipping to several weeks for international economy shipping, depending on the specific services chosen.

Considerations Before Choosing a 3D Print and Ship Service

Material Options

When considering a 3D print and ship service, the available material options are crucial. Different materials have distinct properties, making them suitable for various applications.

One of the most common 3D - printing materials is PLA (Polylactic Acid). PLA is a bioplastic derived from renewable resources like corn starch or sugarcane. It has a relatively low melting point, which makes it easy to print with, especially for beginners. The printing temperature of PLA typically ranges from 190°C - 220°C. It is known for its smooth surface finish and is an environmentally friendly choice as it is biodegradable. However, PLA has its limitations. It has a relatively low heat resistance, softening at around 60°C. This makes it unsuitable for applications that require high - temperature resistance, such as engine parts or cookware. But it is perfect for creating decorative items, prototypes, and educational models. For example, many schools use PLA in their 3D - printing courses to teach students about 3D - printing technology due to its ease of use and non - toxic fumes during printing.

ABS (Acrylonitrile Butadiene Styrene) is another popular thermoplastic. It is more durable and has better heat resistance than PLA, with a heat - deflection temperature of around 100°C. ABS is often used in applications that require higher strength and impact resistance, such as making functional parts for machinery or automotive prototypes. However, printing with ABS can be more challenging. It requires a higher printing temperature, usually between 230°C - 250°C, and often needs a heated build plate to prevent warping. Additionally, ABS emits a pungent odor during printing, so proper ventilation is necessary.

For more industrial or high - performance applications, metal materials like aluminum, stainless steel, and titanium are available for 3D printing. Metal 3D - printed parts offer excellent strength, durability, and heat resistance. Aluminum is lightweight and corrosion - resistant, making it suitable for aerospace and automotive applications where weight reduction is crucial. Stainless steel provides high strength and corrosion resistance, and it is commonly used in the medical and food - processing industries. Titanium is extremely strong and lightweight, with excellent biocompatibility, making it ideal for medical implants. However, metal 3D printing is more expensive due to the high cost of materials and the complex printing process, which often involves high - power lasers or electron beams.

Quality Assurance

Ensuring high - quality 3D prints and reliable shipping is essential when choosing a 3D print and ship service.

Printing accuracy is a fundamental aspect of quality. A high - quality 3D print should closely match the original digital model. The accuracy is often measured in terms of dimensional tolerance. For example, in industrial 3D printing, a tolerance of ±0.1mm or less may be required for critical parts. This means that the actual dimensions of the printed part should be within 0.1mm of the designed dimensions. A service that can consistently achieve such tight tolerances is more likely to produce parts that fit together correctly and function as intended.

Surface finish also plays a significant role in the quality of 3D prints. A smooth surface finish is desirable for many applications, especially those where aesthetics matter or where the part needs to have low friction. Some 3D - printing technologies, like SLA (Stereolithography), generally produce parts with a smoother surface compared to FDM (Fused Deposition Modeling). However, post - processing techniques such as sanding, polishing, or chemical treatments can be applied to improve the surface finish of FDM prints. A good 3D print and ship service should be able to offer options for post - processing to meet your surface - finish requirements.

When it comes to shipping, the service should ensure that the 3D - printed item arrives at its destination in perfect condition. This includes proper packaging to protect the item from damage during transit. A reliable service will use appropriate cushioning materials and sturdy packaging boxes. They should also provide tracking information so that you can monitor the progress of your shipment. The shipping carrier's reputation for on - time delivery and low damage rates is also an important factor to consider. For example, carriers like FedEx and DHL are known for their reliable international shipping services, while the USPS may be a more cost - effective option for domestic shipping in the United States.

Yigu Technology's View

As a non - standard plastic and metal products custom supplier, Yigu Technology highly values the significance of 3D print and ship services. We understand that in today's fast - paced and diverse market, customers have unique demands for product design and functionality. 3D printing enables us to bring our customers' most creative ideas to life, creating customized products that perfectly match their requirements, whether it's a one - of - a - kind plastic prototype or a complex metal component.

With our experienced professional technical team, we are proficient in a wide range of 3D printing technologies. We can select the most suitable technology and materials according to different product needs, ensuring high - quality prints. In terms of quality control, we have a strict system in place. Every 3D - printed product undergoes multiple inspections, from the raw material stage to the final finished product, to guarantee that it meets the highest quality standards.

FAQ

What types of materials can be used for 3D printing in 3D print and ship services?

Commonly used materials include PLA (Polylactic Acid), which is biodegradable, easy to print with a printing temperature of 190°C - 220°C, suitable for decorative items, prototypes, and educational models. ABS (Acrylonitrile Butadiene Styrene) has higher strength and heat - resistance (heat - deflection temperature around 100°C), used for functional parts in machinery or automotive prototypes, but requires a higher printing temperature (230°C - 250°C) and a heated build plate. Metal alloys like aluminum (lightweight and corrosion - resistant for aerospace and automotive), stainless steel (high - strength and corrosion - resistant for medical and food - processing), and titanium (strong, lightweight, and biocompatible for medical implants) are also available for more industrial applications. Resin materials are often used in SLA 3D printing, capable of producing high - detail and smooth - surface parts, suitable for jewelry design and dental models.

How accurate is the 3D printing in a 3D print and ship service?

Generally, the accuracy of 3D printing can vary. For consumer - grade FDM 3D printers, the accuracy is usually around ±0.5mm. Industrial FDM printers can achieve an accuracy of about ±0.2mm. SLA and DLP (Digital Light Processing) 3D printers, which use light to cure resin, have an accuracy of approximately ±0.1mm, and professional resin 3D printers can reach an even higher accuracy of ±0.01mm. However, factors such as the printer's condition, the complexity of the model, and the chosen printing parameters can all affect the final accuracy.

What if my 3D printed item is damaged during shipping?

If your 3D - printed item is damaged during shipping, first, take clear photos of the damaged item and the packaging as evidence. Then, contact the 3D print and ship service's customer support immediately. Provide them with the order details, tracking number, and the photos you took. The service will typically assess the situation. In most cases, they will either offer a compensation based on the value of the item or, if possible, re - print and ship a new item to you to ensure that you receive a satisfactory product.