Understanding Rapid Prototype Machined Parts

Rapid prototype machined parts refer to components produced through machining processes during the rapid prototyping stage. This is a crucial step in product development, allowing companies to quickly create physical models of their designs. These parts are made with high precision, often using advanced CNC (Computer Numerical Control) machining techniques.

Common Application Areas

- Automotive Industry: In the automotive sector, rapid prototype machined parts are used for developing new vehicle models. For example, car manufacturers may create prototypes of engine components, such as cylinder heads or intake manifolds. This helps in testing the functionality and performance of these parts before mass production. A study by a leading automotive research firm found that using rapid prototype machined parts can reduce the development time of a new car model by up to 30%.

- Aerospace Industry: Aerospace companies rely on these parts for aircraft design and development. Components like turbine blades and aircraft brackets are often prototyped first. These prototypes need to meet strict standards in terms of material strength and aerodynamic performance. According to the Aerospace Industries Association, about 80% of new aircraft components go through a rapid prototyping stage.

- Medical Device Manufacturing: When developing new medical devices, such as surgical instruments or prosthetics, rapid prototype machined parts play a vital role. They enable manufacturers to test the fit, functionality, and safety of the devices. For instance, a new type of knee implant may first be created as a rapid prototype to ensure it can withstand the mechanical stresses in the human body.

Types of Rapid Prototype Machined Parts

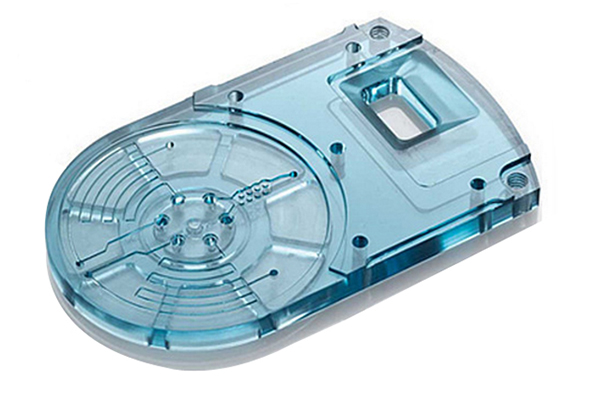

Plastic Rapid Prototype Machined Parts

Plastic rapid prototype machined parts are popular due to their low cost and lightweight nature. They are ideal for applications where weight reduction is crucial, such as in consumer electronics. For example, many smartphone casings are first prototyped in plastic.

Common plastic materials used in rapid prototyping include:

- Acrylonitrile Butadiene Styrene (ABS): ABS is a widely used thermoplastic. It has good mechanical properties, is easy to machine, and has a relatively low cost. It is often used for general - purpose prototypes, such as those in the toy industry. ABS can withstand temperatures up to around 90°C, making it suitable for a variety of indoor applications.

- Polycarbonate (PC): PC is known for its high impact resistance and optical clarity. It can be used to make prototypes of lenses or transparent enclosures. PC has a high heat - deflection temperature, usually around 130 - 140°C, which means it can maintain its shape well under higher temperatures compared to some other plastics.

Metal Rapid Prototype Machined Parts

Metal rapid prototype machined parts offer high strength and excellent heat resistance. They are essential in industries where durability and performance under extreme conditions are required.

Some common metal materials for rapid prototyping are:

- Aluminum: Aluminum is lightweight yet strong. It has a good strength - to - weight ratio, making it suitable for aerospace and automotive applications. For example, in the aerospace industry, aluminum prototypes are used for aircraft structural components. Aluminum alloys can also be heat - treated to improve their mechanical properties. It has a melting point of around 660°C.

- Stainless Steel: Stainless steel is highly corrosion - resistant. It is often used in medical device prototypes and food - processing equipment prototypes. Types like 304 and 316 stainless steel are popular. 316 stainless steel, in particular, has better corrosion resistance in harsh environments, such as those with high salt content, making it ideal for marine - related prototypes.

The Process of Creating Rapid Prototype Machined Parts

The creation of rapid prototype machined parts involves a series of well - defined steps to ensure high - quality and accurate results.

CAD Design

The first step is the Computer - Aided Design (CAD). Designers use specialized software to create a 3D model of the part. This digital model serves as the blueprint for the entire manufacturing process. For example, in the design of a new robotic arm, the CAD model will precisely define the shape, dimensions, and all the intricate details of each component. During this stage, designers can also perform simulations to check for potential design flaws, such as stress points in a mechanical part. According to a survey of design engineers, over 90% of them use CAD software for initial product design.

CAM Programming

Once the CAD model is complete, it is translated into a set of instructions for the machining equipment through Computer - Aided Manufacturing (CAM) programming. The CAM software analyzes the CAD model and generates toolpaths. These toolpaths determine how the cutting tools will move during the machining process. For instance, if the part has complex curves, the CAM program will calculate the most efficient and accurate way for the milling machine to create those curves. The choice of cutting speed, feed rate, and depth of cut are also defined in the CAM programming, which significantly affects the surface finish and dimensional accuracy of the final part.

### 加工制造

In the manufacturing stage, the actual machining of the part takes place. CNC machines, such as milling machines, lathes, or EDM (Electrical Discharge Machining) machines, are used. For plastic parts, CNC milling is a common method. The machine removes material from a plastic block according to the toolpaths generated by the CAM program. In metal machining, a lathe might be used to create cylindrical parts. For example, when making a metal shaft, the lathe rotates the metal workpiece while a cutting tool shapes it to the desired dimensions. The accuracy of modern CNC machines can reach tolerances as low as ±0.001 inches, ensuring high - precision parts.

### 后处理

After the machining is complete, post - processing is often required. This step can include operations like sanding, polishing, and coating. Sanding is used to smooth the surface of the part, removing any rough edges or tool marks left during machining. Polishing can enhance the part's appearance and surface finish, making it suitable for applications where aesthetics matter, such as in consumer product prototypes. Coating may be applied for protection or functional purposes. For example, a corrosion - resistant coating can be added to metal prototypes to prevent rusting.

Comparison with Other Prototyping Methods

When considering prototyping for product development, it's essential to understand how rapid prototype machined parts compare to other methods. Here is a comparison between rapid prototype machining, 3D printing, and hand - made prototyping in terms of cost, precision, speed, and design complexity:

| Prototyping Method | Cost | Precision | Speed | Design Complexity |

| Rapid Prototype Machining | High - medium. Higher initial setup costs due to CNC equipment, but cost - effective for mid - to high - volume prototypes. | High. Tolerances can reach as low as ±0.001 inches. | Medium. Depends on part complexity and size, but generally faster than some 3D printing methods for larger parts. | Good for complex parts, but very intricate internal geometries can be challenging. |

| 3D Printing | Low - medium for small, simple prototypes. High for large or complex parts with expensive materials. | Medium - high, depending on the 3D printing technology. Some technologies can achieve high precision, but surface finish may require post - processing. | Slow for large or complex models. Can be fast for small, simple parts. | Excellent for highly complex and organic designs, including internal lattice structures. |

| Hand - made Prototyping | Low in terms of equipment cost, but high in labor cost. | Low - medium. Limited by human skill, may have less consistent precision. | Slow, especially for complex designs. | Limited. Difficult to create highly precise and complex shapes. |

For example, if you need a prototype of a simple plastic bracket for a consumer electronics product, 3D printing might be a cost - effective and quick option for a single - unit prototype. However, if you require multiple prototypes with high precision and the part is made of metal, rapid prototype machining would be a better choice. Hand - made prototyping could be suitable for very low - budget projects where precision and speed are not critical, such as creating a rough concept model for a design brainstorming session.

Yigu Technology's View

As a non - standard plastic and metal products custom supplier, Yigu Technology highly values the importance of rapid prototype machined parts. Our state - of - the - art facilities and experienced team enable us to produce high - quality rapid prototype machined parts with tight tolerances.

We offer a wide range of services, from initial CAD design to the final post - processing of the parts. Our design team can work closely with clients to optimize the design for manufacturability, ensuring that the final prototype meets all the requirements. In terms of materials, we have access to a vast selection of plastics and metals, allowing us to provide the most suitable material for each project.

What sets us apart is our quick turnaround time. We understand the importance of speed in product development, and we strive to deliver rapid prototype machined parts in the shortest possible time without compromising on quality.

FAQ

What materials can be used for rapid prototype machined parts?

Common materials include plastics like ABS and polycarbonate, and metals such as aluminum and stainless steel. The choice depends on the application requirements, such as weight, strength, heat resistance, and cost. For example, ABS is great for general - purpose and cost - sensitive prototypes, while aluminum is preferred for aerospace applications due to its high strength - to - weight ratio.

How accurate are rapid prototype machined parts?

The accuracy of rapid prototype machined parts can reach tolerances as low as ±0.001 inches. However, factors like the machining equipment, the complexity of the part, and the skill of the operator can affect the final accuracy. High - end CNC machines with advanced control systems generally offer better accuracy.

What is the typical lead time for producing rapid prototype machined parts?

The lead time usually ranges from a few days to a couple of weeks. For simple parts, it may take only 3 - 5 days. But for complex parts with multiple operations and tight tolerances, it could be 1 - 2 weeks. Factors affecting the lead time include the complexity of the design, the availability of materials, and the workload of the manufacturing facility.