Introduction to Additive Manufacturing

Additive manufacturing (AM), commonly referred to as 3D printing, is a transformative and innovative technology that has reshaped the product design and manufacturing process. Unlike traditional subtractive manufacturing methods, where material is removed from a larger block to create the desired shape, additive manufacturing builds objects layer by layer from a digital design. This process allows for the production of highly customized, complex, and efficient products with minimal waste. As the technology continues to advance, additive manufacturing is being used in a wide range of industries, from aerospace to consumer products, enabling new opportunities for innovation, efficiency, and sustainability.

Definition and Overview

What is Additive Manufacturing?

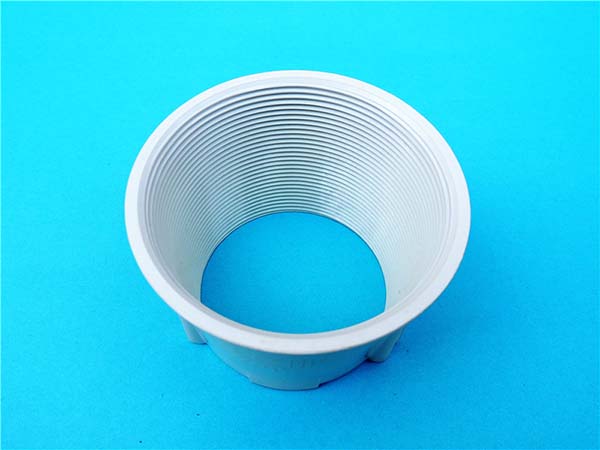

Additive manufacturing is the process of creating three-dimensional objects directly from a digital file by successively adding layers of material. This contrasts with traditional manufacturing methods, which typically involve removing material from a larger block. The core principle of AM is the use of Computer-Aided Design (CAD) software to create detailed blueprints, which are then translated into physical objects through various 3D printing technologies, such as Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA).

How Does It Work?

The additive manufacturing process involves several key steps:

- Design: A 3D model of the object is created using CAD software or scanned from a physical object.

- Preparation: The 3D model is then "sliced" into thin layers using slicing software, which prepares the digital design for printing.

- Printing: The 3D printer reads the sliced file and prints each layer of material, building the object layer by layer.

- Finishing: After printing, the object may require post-processing steps such as sanding, painting, or curing to enhance its appearance or functionality.

Historical Development

The concept of additive manufacturing dates back to the 1980s, when Chuck Hull invented stereolithography (SLA), the first widely adopted 3D printing technology. Key developments in AM have spanned several decades, with each technological breakthrough paving the way for broader applications. Notable milestones in AM history include:

- 1984: Chuck Hull patents stereolithography, the first 3D printing technology.

- 1988: The first commercial 3D printer, the SLA-1, is introduced by 3D Systems.

- 1993: The introduction of Selective Laser Sintering (SLS) by Carl Deckard and Joe Beaman at the University of Texas.

- 2008: The RepRap project introduces the first affordable desktop 3D printer, democratizing access to 3D printing.

- 2010s: The advent of metal 3D printing technologies such as Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) enables the production of functional metal parts.

Key Characteristics of Additive Manufacturing Products

1. Customization

One of the most prominent advantages of additive manufacturing is its ability to produce highly customized products. Unlike traditional manufacturing methods, which often require the creation of expensive molds or tooling, AM allows for the cost-effective production of one-off items or small batches with relative ease. This is especially useful in industries that require personalized solutions, such as healthcare (for custom implants and prosthetics), fashion (for personalized accessories), and automotive (for custom-fit parts).

- Example: In the medical field, 3D printing allows for the creation of patient-specific implants and prosthetics that are tailored to individual anatomical requirements, improving both comfort and functionality.

2. Complexity and Design Freedom

Additive manufacturing provides unprecedented design freedom by enabling the creation of intricate geometries and complex internal structures. Traditional manufacturing methods, such as injection molding or CNC machining, often impose limitations on the shapes that can be produced. In contrast, AM allows for the creation of parts with complex internal features, hollow spaces, and organic shapes that enhance performance, functionality, and aesthetics.

- Example: Aerospace components, such as fuel nozzles and brackets, are 3D printed with complex geometries that would be impossible to produce with traditional methods. This capability has revolutionized lightweighting efforts in aerospace and automotive industries.

3. Lightweight and Material Efficiency

Additive manufacturing is inherently material-efficient. Since material is added only where needed, there is little to no waste during the production process. Additionally, AM's ability to create lightweight lattice structures and honeycomb patterns results in parts that maintain strength while reducing overall weight. This is particularly important in industries like aerospace and automotive, where weight reduction leads to better fuel efficiency and performance.

- Example: In the aerospace industry, companies like GE Aviation have leveraged 3D printing to create lightweight fuel nozzles that offer improved durability and performance, while reducing the weight of the component by 25%.

Applications of Additive Manufacturing

1. Aerospace Industry

Additive manufacturing is transforming the aerospace industry by enabling the production of lightweight, high-performance parts that are both stronger and more cost-effective than traditionally manufactured components. AM also facilitates rapid prototyping, allowing engineers to test and iterate designs quickly.

- Example: GE Aviation uses 3D printing to create fuel nozzles for its LEAP engine, resulting in a 25% weight reduction and increased durability compared to traditionally made parts. Similarly, NASA has explored AM for producing rocket parts and other critical components for space missions.

2. Automotive Sector

In the automotive industry, additive manufacturing is used to produce prototype parts, functional components, and lightweight structures. The ability to print parts on demand accelerates production cycles and reduces inventory costs. AM is also used to create custom parts and to improve vehicle design through rapid prototyping.

- Example: Ford and BMW have integrated 3D printing into their manufacturing processes, with applications ranging from customized car parts to rapid prototyping for new models.

3. Medical Field

The medical field has been one of the most impactful beneficiaries of additive manufacturing. AM is used to create custom prosthetics, implants, surgical guides, and even bioprinted tissues. The ability to produce patient-specific items improves the efficacy and comfort of medical devices, while reducing costs associated with mass production.

- Example: SmileDirectClub uses 3D printing to create custom clear aligners, while surgeons use 3D-printed anatomical models and surgical guides to improve precision in complex surgeries.

4. Consumer Goods

Additive manufacturing has revolutionized the consumer goods industry by allowing for customized products and personalized designs. From custom jewelry to fashion accessories, 3D printing enables consumers to order unique items that are tailored to their tastes and preferences.

- Example: Nike has explored 3D printing for customized footwear, offering personalized shoe designs that enhance comfort and performance. Companies like Formlabs also make desktop 3D printers available to hobbyists and small businesses, broadening access to 3D printing technology.

Advantages Over Traditional Manufacturing

1. Waste Reduction

Additive manufacturing is inherently more sustainable than traditional methods, as it produces minimal material waste. Since objects are built layer by layer, only the required amount of material is used, reducing the waste commonly associated with subtractive processes like CNC machining, which removes excess material.

- Example: In industries like aerospace and automotive, where the material cost is high, AM helps reduce waste and lower overall production costs.

2. Prototyping Speed

AM enables rapid prototyping, allowing engineers and designers to quickly produce physical models from digital files. This accelerates product development cycles, enabling businesses to test designs, make modifications, and bring new products to market faster than ever before.

- Example: In product development, AM helps companies like Ford and BMW to rapidly iterate prototype parts for vehicles, leading to faster testing and production cycles.

3. Intricate Design Capabilities

AM allows for intricate design possibilities that traditional manufacturing cannot achieve. Internal structures, lattice designs, and organic shapes can be easily incorporated into designs without the need for specialized tooling or molds.

- Example: Aerospace components, such as brackets and fuel nozzles, are often made with highly complex geometries that provide both strength and lightweight properties, something not feasible with conventional techniques.

FAQs

What materials can be used in additive manufacturing?

Additive manufacturing supports a wide range of materials, including plastics (e.g., PLA, ABS, nylon), metals (e.g., titanium, aluminum, stainless steel), ceramics, and composites. Different materials are suited for different applications, ranging from biocompatible materials for medical uses to high-strength metals for aerospace applications.

Is additive manufacturing cost-effective for large-scale production?

While additive manufacturing excels in rapid prototyping and low-volume production, it is typically less cost-effective for large-scale manufacturing due to the higher initial setup costs for 3D printers and the slower printing speeds compared to traditional mass production methods. However, as the technology advances and becomes more widespread, it may become more viable for mass production in some industries.

How does additive manufacturing impact sustainability?

Additive manufacturing can have a positive impact on sustainability by reducing material waste, using recycled materials, and creating products on demand—minimizing the need for large inventories and long supply chains. However, the environmental impact of the energy consumption of 3D printers and the disposal of 3D printed objects should also be considered in the overall sustainability equation.

In conclusion, additive manufacturing represents a game-changing technology that has already proven its value in industries such as aerospace, automotive, medical, and consumer goods. The ability to customize, produce complex geometries, and reduce waste offers vast opportunities for innovation, efficiency, and sustainability across multiple sectors.