Introduction to CNC Machining

Definition and Process

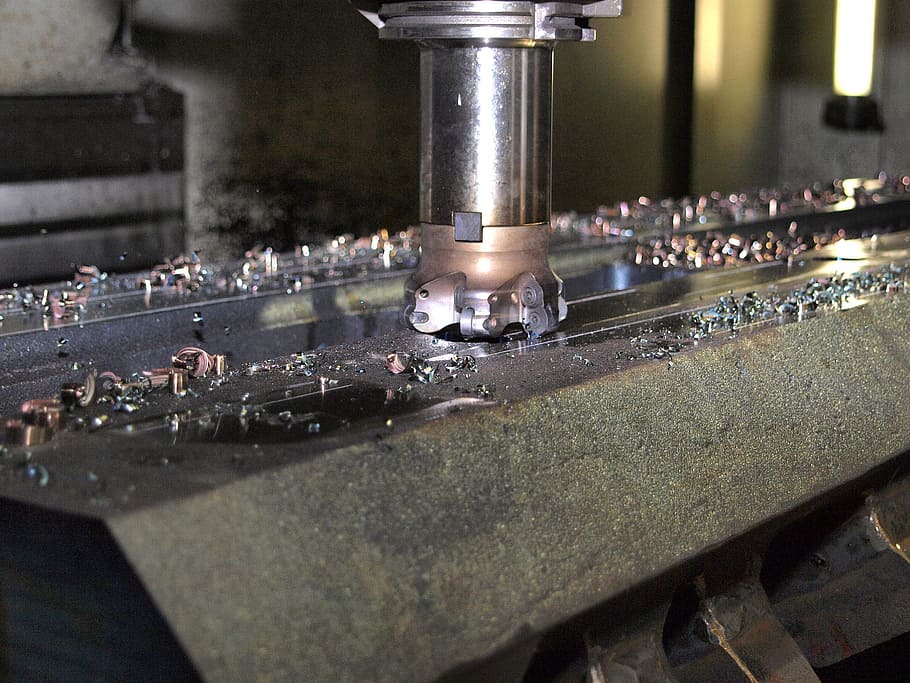

CNC machining is a subtractive manufacturing process where pre-programmed software guides machinery to remove material from a workpiece. It creates precision components by cutting, drilling, milling, or turning. This process is versatile and accommodates a wide range of materials, such as metals, plastics, and composites, making it a go-to method for industries requiring high accuracy and durability.

Advantages of CNC Machining

- High Precision: Offers tight tolerances and repeatable accuracy.

- Versatile Material Compatibility: Works with metals, plastics, and composites.

- Efficient for Large Batches: Economical for mass production after setup.

- Durability and Strength: Produces robust parts for demanding applications.

- Advanced Capabilities: Handles complex geometries and intricate details.

Introduction to Rapid Prototyping

Definition and Process

Custom Rapid prototyping, commonly associated with 3D printing, is an additive manufacturing process. It builds parts layer by layer from digital designs, using technologies such as FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering). This process is efficient for creating prototypes and low-volume custom parts.

Advantages of Rapid Prototyping

- Speed: Produces parts quickly, reducing lead times.

- Low Initial Costs: Eliminates the need for tooling, making it ideal for prototypes.

- Design Flexibility: Easily creates complex geometries, including hollow structures.

- Customization: Allows for unique or iterative designs without additional expense.

- Material Variety: Expanding options include plastics, metals, and resins.

Key Comparisons Between CNC Machining and Rapid Prototyping

1. Manufacturing Process

- CNC Machining: Subtractive—removes material to create the part.

- Rapid Prototyping: Additive—builds the part layer by layer.

2. Material Range

- CNC Machining: Handles a wider variety of materials, including high-strength metals like titanium and hardened steel.

- Rapid Prototyping: Primarily uses plastics and lightweight materials but is expanding into metals with technologies like metal SLS.

3. Speed and Setup

- CNC Machining: Requires setup for tooling and programming, which increases initial production time.

- Rapid Prototyping: Minimal setup allows faster production for initial prototypes.

4. Cost Efficiency

- Low Volume: Rapid prototyping is more cost-effective due to low setup costs.

- High Volume: CNC machining becomes more economical as setup costs are distributed across larger production runs.

5. Part Complexity

- CNC Machining: Excels at precise, complex geometries but may struggle with internal cavities or intricate overhangs.

- Rapid Prototyping: Easily creates highly complex shapes, including internal structures, without additional cost.

6. Surface Finish and Tolerances

- CNC Machining: Provides superior surface finishes and tight tolerances, suitable for functional parts.

- Rapid Prototyping: May require post-processing to achieve smooth finishes or precise dimensions.

7. Waste Management

- CNC Machining: Generates more material waste due to its subtractive nature.

- Rapid Prototyping: Produces minimal waste, as material is only used where needed.

Use Cases and Industry Applications

CNC Machining

- Aerospace: High-precision parts such as turbine blades and structural components.

- Automotive: Engine components, gears, and custom molds for body panels.

- Medical Devices: Surgical tools, implants, and orthopedic devices.

- Electronics: Durable housings and heat sinks.

Rapid Prototyping

- Consumer Electronics: Early-stage design models for devices like smartphones.

- Healthcare: Custom prosthetics and dental implants tailored to individual needs.

- Architecture: Detailed scale models of buildings and structures.

- R&D: Iterative testing of product designs during development.

When to Choose CNC Machining vs. Rapid Prototyping

Choose CNC Machining When:

- High precision and tight tolerances are required.

- The part needs to withstand mechanical stresses (e.g., metal components).

- Production involves large volumes or long-term use.

- Surface finish and dimensional accuracy are critical.

Choose Rapid Prototyping When:

- Speed is essential for initial design iterations.

- You need to evaluate multiple prototypes quickly.

- Complex geometries are involved that would be costly to machine.

- Low-volume or custom parts are sufficient for the application.

Future Trends in CNC Machining and Rapid Prototyping

1. Hybrid Manufacturing

Combining CNC machining and rapid prototyping offers the best of both worlds. For example, additive manufacturing can create base structures, while CNC machining finishes surfaces and ensures precision.

2. AI and Automation

Advanced AI algorithms in CNC machines and 3D printers can optimize toolpaths, reduce errors, and enhance material efficiency.

3. Expanded Material Options

Both processes are incorporating new materials, such as bio-compatible polymers for medical applications and lightweight composites for aerospace and automotive industries.

4. Sustainability Initiatives

Efforts to reduce waste and improve energy efficiency are driving innovations in both subtractive and additive manufacturing.

Conclusion

CNC machining and rapid prototyping are complementary technologies, each suited to specific phases of the manufacturing process. CNC machining excels in high-precision, high-volume applications where durability and tight tolerances are paramount. Rapid prototyping shines in early-stage product development, offering speed, flexibility, and cost savings for low-volume production. Leveraging both methods strategically can accelerate product development and enhance manufacturing efficiency.

FAQs

What is the primary difference between CNC machining and rapid prototyping?

The primary difference lies in their manufacturing processes: CNC machining is a subtractive process that removes material to shape a part, while rapid prototyping is an additive process that builds parts layer by layer from the bottom up.

Which process is more cost-effective for low-volume production?

For low-volume production, rapid prototyping is generally more cost-effective because it eliminates the need for expensive tooling and allows for quicker production cycles without significant setup costs.

When should I choose CNC machining over rapid prototyping?

You should choose CNC machining when you need high precision, are working with hard materials, or require mass production. CNC machining is ideal for applications where tight tolerances and material strength are critical, such as in the automotive or aerospace industries.