Introduction to CNC Machining Services

CNC (Computer Numerical Control) machining services have revolutionized modern manufacturing by combining automation, precision, and versatility. By translating digital designs into physical parts with micrometer - level accuracy, CNC technology addresses critical challenges in industries ranging from aerospace to medical devices. Yigu Technology explores how CNC machining services deliver consistent quality, cost efficiency, and rapid prototyping capabilities, supported by technical insights and real - world applications.

The Basics of CNC Machining

At its core, CNC machining involves the use of pre - programmed computer software to control the movement of factory tools and machinery. This automation replaces manual control, enabling a level of precision that is difficult to achieve through traditional machining methods. The process starts with a CAD (Computer - Aided Design) model, which is then converted into a CAM (Computer - Aided Manufacturing) program. This program generates G - codes, a set of instructions that the CNC machine reads to perform operations such as milling, turning, drilling, and grinding.

CNC machines can operate on a variety of axes. The most common are 3 - axis machines, which can move along the X, Y, and Z axes, allowing for basic 3D shaping. 4 - axis machines add rotational movement around one of the linear axes, typically the Z - axis, which is useful for more complex geometries. 5 - axis machines, the most advanced in common use, offer even greater flexibility by allowing rotation around two additional axes (usually A and B), enabling the machining of highly intricate parts in a single setup.

Precision and Accuracy: The Hallmark of CNC Machining

One of the most significant advantages of CNC machining services is their ability to achieve extremely high precision. Tolerances as tight as ±0.001 inches (±0.0254 mm) are achievable in many cases, which is crucial for industries like aerospace and medical device manufacturing.

For Yigu Technology example, in aerospace, components such as turbine blades require precise manufacturing to ensure optimal performance. A slight deviation in the shape or dimensions of a turbine blade can lead to inefficiencies in the engine, reduced fuel efficiency, and potentially catastrophic failures. CNC machining allows for the production of these blades with the necessary precision, ensuring that they meet the strictest quality standards.

In the medical field, implants also demand high - precision manufacturing. A hip implant, for instance, must fit precisely into the patient's body to function correctly and minimize the risk of complications. CNC - machined implants can be customized to match the patient's unique anatomy, thanks to the high - precision capabilities of CNC technology.

Cost - Efficiency in the Long Run

While the initial investment in CNC machining equipment can be substantial, the long - term cost - efficiency is often a major selling point for businesses. CNC machines reduce labor costs as they can operate continuously with minimal human intervention once the program is set up. Additionally, the high precision of CNC machining reduces material waste. Since parts are produced with a high degree of accuracy, there are fewer rejects, which saves on the cost of raw materials.

Consider a comparison between traditional machining and CNC machining in a production run of 10,000 parts. In traditional machining, due to human error and the need for manual adjustments, the rejection rate might be 5%. In a CNC - machining process, the rejection rate could be as low as 1%. If the cost of raw materials per part is \(10, in the traditional machining scenario, the cost of wasted materials would be \)5,000 (500 parts * \(10), while in the CNC - machining scenario, it would be only \)1,000 (100 parts * $10). Over time, these savings can be significant, especially for high - volume production runs.

Rapid Prototyping and Iteration

CNC machining services are also invaluable for rapid prototyping. Designers and engineers can quickly transform their digital concepts into physical prototypes using CNC machines. This allows for rapid testing and iteration, reducing the time it takes to bring a product to market.

For example, a start - up in the consumer electronics industry might develop a new smartphone case design. Using CNC machining, they can produce a prototype within a few days. This prototype can then be tested for fit, functionality, and aesthetics. Based on the feedback, the design can be modified, and a new prototype can be produced just as quickly. This iterative process can be repeated until the design is perfected, all without the need for expensive and time - consuming tooling changes as would be required in some traditional manufacturing methods.

In conclusion, CNC machining services offer a wide range of benefits that make them an essential part of modern manufacturing. From their high precision and accuracy to cost - efficiency and rapid prototyping capabilities, CNC machines are enabling industries to produce high - quality products faster and more affordably than ever before. The following sections will explore the different types of CNC machining processes, the materials that can be used, and real - world case studies that demonstrate the power of CNC machining in action.

The Fundamentals of CNC Machining

How CNC Machines Work

CNC machines operate based on a set of pre - programmed instructions that control the movement of cutting tools relative to the workpiece. This is a far cry from traditional manual machining, where human operators directly manipulate the tools. In CNC machining, the process begins with a digital design, typically created using CAD software. This design is then translated into a CAM program, which generates G - codes.

G - codes are the language that CNC machines understand. They specify details such as the speed of the spindle, the feed rate of the cutting tool, and the precise path the tool should follow. For Yigu Technology example, a G - code instruction might tell the machine to move the cutting tool 50 millimeters along the X - axis at a feed rate of 100 millimeters per minute.

The CNC machine's control unit reads these G - codes and sends signals to the servo - motors that drive the axes of the machine. These servo - motors ensure that the cutting tool moves with extreme precision, following the programmed path to create the desired part. This automation not only reduces the risk of human - error but also enables the production of parts with a high degree of repeatability. Once the program is set up correctly, the CNC machine can produce identical parts time and time again, making it ideal for mass production.

Key Processes

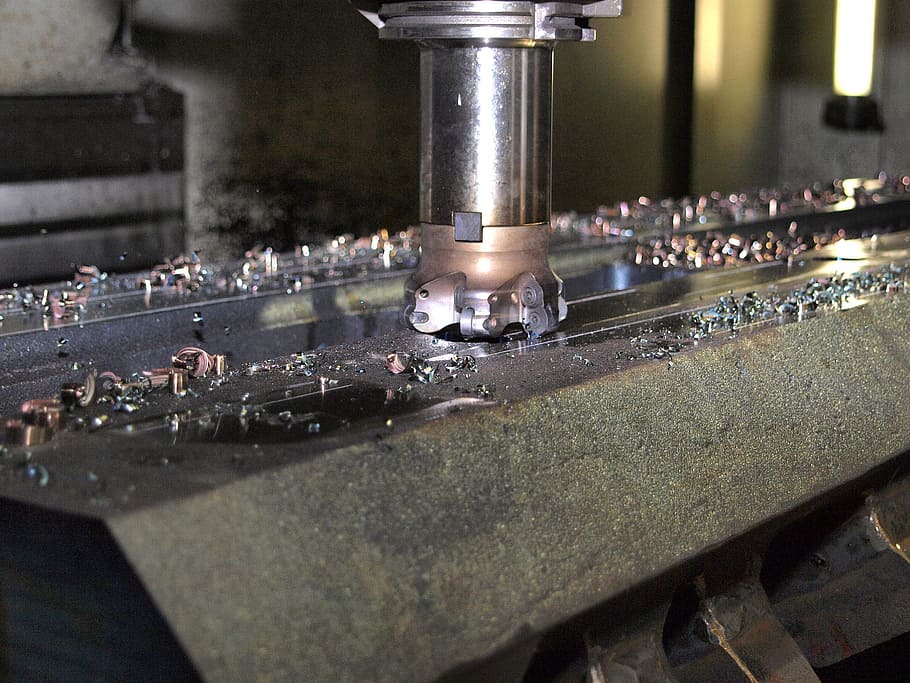

- CNC Milling

- CNC milling is a versatile process that uses rotating cutters to remove material from a workpiece and shape it into the desired 3D form. The cutters can move along multiple axes (usually 3, 4, or 5 axes) to create complex geometries. For instance, in the production of a custom - designed aluminum bracket for an industrial machine, a 3 - axis CNC milling machine might be used. The milling cutter would first rough - cut the basic shape of the bracket, removing large amounts of excess material. Then, in a series of finer passes, it would create the precise holes, slots, and edges required for the bracket to function properly.

- The versatility of CNC milling allows it to work with a wide range of materials, from soft plastics to hard metals like steel. The feed rate, spindle speed, and depth of cut can be adjusted according to the material properties. For Yigu Technology example, when milling soft plastics, a higher spindle speed and feed rate can be used, while for hard metals, a slower spindle speed and shallower depth of cut are often required to prevent overheating and tool wear.

- CNC Turning

- CNC turning is primarily used to create cylindrical components. In this process, the workpiece is rotated on a lathe while a stationary cutting tool removes material to shape the outer diameter, inner diameter, or end - face of the workpiece. A common example is the production of shafts for engines. The raw material, often a metal rod, is clamped onto the lathe's chuck and rotated at high speeds. The cutting tool, which is mounted on a tool post, is then moved in a controlled manner to create the desired shape, such as a stepped shaft with different diameters at various sections.

- Different types of CNC turning machines offer various capabilities. Conventional CNC lathes are suitable for a wide range of turning operations, from simple to moderately complex. Swiss lathes, on the other hand, are designed for high - precision machining of small, intricate parts. They use a guide bushing to support the workpiece close to the cutting area, enabling extremely tight tolerances. Turning centers are more advanced, with features like multiple turrets and live tooling, allowing for additional operations such as milling and drilling to be performed on the rotating workpiece.

- EDM (Electrical Discharge Machining)

- EDM is a unique machining process that uses electrical discharges to erode material from a conductive workpiece. It is particularly useful for creating intricate shapes that are difficult to achieve with traditional machining methods. The process involves a tool electrode (usually made of copper or graphite) and the workpiece, both submerged in a dielectric fluid (such as kerosene or de - ionized water). When a high - voltage pulse is applied between the electrode and the workpiece, a spark is generated, which heats and vaporizes a small amount of the workpiece material.

- For example, in the production of injection molds with complex internal geometries, EDM can be used to create the fine details and cavities. Since EDM does not rely on mechanical cutting forces, it can machine very hard materials, such as hardened steel, without causing stress or deformation. However, EDM is a relatively slow process compared to milling or turning, so it is often used for parts where precision and the ability to create complex shapes are more important than speed.

Advantages of CNC Machining Services

Precision and Consistency

One of the most significant selling points of CNC machining services is their unparalleled precision. With tolerances as tight as ±0.001mm in advanced setups, CNC machines can produce parts with an accuracy that is difficult to achieve through traditional machining methods. This level of precision is crucial in industries such as aerospace, where components like fasteners must fit together perfectly to ensure the safety and efficiency of an aircraft. A deviation of even a fraction of a millimeter in an aerospace fastener could lead to structural integrity issues, potentially resulting in catastrophic failures during flight.

Moreover, CNC machining offers remarkable consistency. Once the machining program is set up correctly, the machine can produce identical parts indefinitely. This repeatability minimizes variability between parts, which is essential for mass production. For Yigu Technology example, in the automotive industry, thousands of identical engine components need to be produced. CNC machining ensures that each component has the same dimensions and quality, reducing the need for extensive quality - control checks and minimizing the risk of assembly issues down the line. A study in a large - scale automotive manufacturing plant found that by switching to CNC machining for engine block production, the defect rate decreased from 5% (with traditional machining) to less than 1%, leading to significant cost savings in terms of both material waste and rework.

CNC Machining Materials

CNC machining services support a wide range of materials, making them suitable for diverse applications. Among the metals, aluminum is a popular choice due to its low density, high strength - to - weight ratio, and excellent machinability. It is widely used in the aerospace, automotive, and electronics industries. For instance, in the aerospace industry, aluminum is used to manufacture aircraft wings and fuselage components, where its lightweight properties contribute to fuel efficiency. Stainless steel, on the other hand, is valued for its corrosion resistance, high strength, and heat resistance. It is commonly used in the food processing, medical, and marine industries. In the medical field, stainless - steel surgical instruments need to be corrosion - resistant to maintain their functionality and hygiene over time. Titanium is another metal used in CNC machining, especially in applications where high strength and biocompatibility are required, such as in medical implants and aerospace components.

When it comes to plastics, POM (Polyoxymethylene) is known for its high stiffness, low friction, and good dimensional stability. It is often used in small mechanical parts, such as gears and bearings. PEEK (Polyetheretherketone) is a high - performance thermoplastic with excellent chemical resistance, high - temperature stability, and mechanical strength. It is used in demanding applications like aerospace components and medical devices. ABS (Acrylonitrile Butadiene Styrene) is a more common plastic, valued for its affordability, ease of machining, and good impact resistance. It is widely used in consumer electronics, toys, and automotive interior parts.

In addition to the base materials, various surface finishes can be applied to enhance the durability and appearance of CNC - machined parts. Anodizing is a popular surface treatment for aluminum parts. It creates a protective oxide layer on the surface, improving corrosion resistance and providing a decorative finish. Powder coating can be applied to both metals and plastics, offering a durable, attractive, and corrosion - resistant finish. For example, in outdoor furniture production, powder - coated aluminum parts can withstand harsh weather conditions for years without significant degradation.

Efficiency and Speed

- Rapid Prototyping

CNC machining services are a boon for rapid prototyping. In as little as 1 - 3 days, a concept can be transformed into a functional prototype. This speed is invaluable for product development teams. Consider a start - up in the robotics industry. They have an innovative design for a new robotic arm joint. Using CNC machining, they can quickly produce a prototype of the joint. This prototype can then be tested for functionality, strength, and compatibility with other components of the robotic arm. Based on the test results, the design can be refined, and a new prototype can be produced just as quickly. This iterative process allows for rapid development and reduces the time it takes to bring the product to market. In contrast, traditional prototyping methods, such as manual machining or casting, can take weeks or even months to produce a single prototype, delaying the product development cycle.

- Low - Volume Production

CNC machining also offers scalable solutions for low - volume production, with batch sizes ranging from 10 to 10,000+ parts. This makes it ideal for market testing. A small - to - medium - sized business that has developed a new consumer product, like a unique kitchen gadget, can use CNC machining to produce a small batch of 100 - 500 units. These units can be sold in select markets or to early adopters to gather feedback. Based on the market response, the company can make improvements to the product design and then scale up production if there is sufficient demand. The ability to produce small batches cost - effectively with CNC machining reduces the financial risk associated with large - scale production runs before the product's market viability is proven.

In summary, the advantages of CNC machining services, including precision, material versatility, and efficiency, make it an essential manufacturing technology for a wide range of industries. The next section will explore real - world case studies that further illustrate the practical applications and benefits of CNC machining.

Applications Across Industries

Automotive Manufacturing

- Engine Components

- The automotive industry demands components that can withstand high - stress environments while delivering optimal performance. CNC - machined cylinder heads are a prime example. These components are responsible for housing the valves, spark plugs, and fuel injectors in an engine. The precision of CNC machining ensures that the ports for air - fuel mixture intake and exhaust are accurately shaped. For instance, a well - machined intake port can improve the volumetric efficiency of the engine, allowing for better combustion and increased power output. In a study comparing engines with traditionally - made and CNC - machined cylinder heads, the CNC - machined ones showed a 5 - 8% increase in power and a 3 - 5% improvement in fuel efficiency.

- Gears are another critical engine component. CNC - machined gears have precise tooth profiles, which reduce noise, vibration, and wear. The high - precision manufacturing process ensures that the gears mesh smoothly, transmitting power efficiently. A common application is in the transmission system. For example, in a manual transmission, CNC - machined gears enable seamless gear - shifting, enhancing the driving experience. The tolerance in CNC - machined gears can be controlled within ±0.002 inches, which is far more precise than traditional manufacturing methods, leading to longer - lasting and more reliable transmissions.

- Custom Tooling

- Assembly lines in automotive manufacturing rely on jigs and fixtures to ensure the accurate positioning of parts during the assembly process. CNC - machined jigs and fixtures are designed to fit specific parts precisely. For example, a jig used to assemble the dashboard of a car can hold all the components, such as the instrument cluster, air vents, and control panels, in their exact positions. This reduces the risk of misalignment, which can lead to issues like gaps between components or problems with the functionality of electrical connections.

- By using CNC - machined fixtures, automotive manufacturers have reported a 30 - 40% reduction in assembly - line downtime. These fixtures are also ergonomically designed, making it easier for workers to handle parts. For instance, a fixture can be designed with handles or grips that are easy to hold, reducing the physical strain on workers during repetitive assembly tasks. This not only improves the working conditions but also increases productivity, as workers can perform their tasks more efficiently without getting fatigued as quickly.

Aerospace

- Titanium Alloy Parts

- In the aerospace industry, weight reduction is crucial for improving fuel efficiency and overall performance. Titanium alloy parts, which are lightweight yet possess high strength, are ideal for aircraft structures. For example, the fuselage of an aircraft contains many titanium alloy components. These parts are CNC - machined to exact specifications to ensure they can withstand the stresses of flight, including air pressure, turbulence, and temperature changes.

- The use of titanium alloys in aircraft structures has increased significantly over the past few decades. In modern commercial aircraft, titanium alloys can account for up to 15 - 20% of the total airframe weight. CNC machining allows for the creation of complex shapes in titanium alloys, such as the curved sections of the fuselage or the intricate joints that connect different parts of the aircraft. The high - precision nature of CNC machining ensures that these parts fit together perfectly, maintaining the structural integrity of the aircraft.

- Jet Engine Turbines

- Jet engine turbines are among the most critical components of an aircraft engine. The blades of these turbines are precision - machined using CNC technology. The shape of the turbine blades is designed to optimize the flow of hot gases, which in turn drives the rotation of the turbine and generates thrust. A slight deviation in the blade's shape can lead to a significant decrease in engine efficiency.

- CNC - machined turbine blades can achieve tolerances of ±0.0005 inches. This high level of precision ensures that the blades operate at their optimal efficiency, improving fuel consumption. For example, a well - designed and precisely - machined turbine blade can increase the engine's thrust - to - fuel - consumption ratio by 3 - 5%, resulting in significant fuel savings over the lifespan of an aircraft. Additionally, the high - strength materials used in combination with CNC machining ensure that the blades can withstand the extreme temperatures and rotational forces present in a jet engine.

Medical Devices

- Surgical Instruments

- Laparoscopic tools, which are used in minimally invasive surgeries, require complex geometries. CNC machining enables the production of these tools with high precision. For example, the jaws of a laparoscopic grasping instrument need to be precisely shaped to grip tissue gently yet firmly. CNC - machined laparoscopic tools can have intricate surface textures and geometries that improve their functionality. The tips of these tools can be designed with micro - serrations to enhance grip without causing excessive damage to the tissue.

- Orthopedic implants, such as knee and hip replacements, also benefit from CNC machining. These implants must be custom - fit to the patient's anatomy. Using 3D scanning technology in combination with CNC machining, manufacturers can create implants that match the patient's unique bone structure. A study showed that patients with CNC - machined orthopedic implants had a 20 - 30% faster recovery time compared to those with conventionally - made implants, as the better - fitting implants caused less stress on the surrounding tissues.

- Medical Implants

- Biocompatible materials like stainless steel and titanium are commonly used for medical implants. CNC machining is used to shape these materials into the exact specifications required for the implant. For example, a spinal implant made of titanium needs to have precise dimensions to fit between the vertebrae and provide proper support. The surface finish of the implant is also crucial, as it can affect the body's response to the implant. CNC - machined implants can have a smooth surface finish, which reduces the risk of inflammation and improves the implant's long - term stability.

- In the case of dental implants, CNC - machining allows for the creation of implants with a high level of accuracy. These implants are designed to integrate with the jawbone, and the precise fit provided by CNC machining increases the success rate of the implant procedure. The success rate of CNC - machined dental implants is over 95% in most cases, compared to a slightly lower rate for implants made with less precise manufacturing methods.

CNC Machining vs. Traditional Methods: A Comparative Analysis

- Precision and Tolerance

- CNC machining offers an extraordinary level of precision. As mentioned earlier, it can achieve tolerances as tight as ±0.001mm in advanced setups. In contrast, traditional machining methods, such as manual milling or turning, typically have a tolerance range of around ±0.1mm. For example, in the production of optical components like lenses, the precision of CNC machining is crucial. A lens with even a slight deviation in curvature can lead to optical aberrations, affecting the quality of images. CNC - machined lenses can be produced with the exact curvature and surface finish required, ensuring high - quality optical performance, while traditional methods would struggle to meet the strict tolerances demanded by the optics industry.

- The following Yigu Technology table clearly shows the difference in precision between CNC machining and traditional methods:

| Machining Method | Tolerance |

|------------------|-----------|

| CNC Machining | ±0.001mm |

| Traditional Machining | ±0.1mm |

- Material Waste

- Material waste is a significant factor in manufacturing costs. CNC machining is more efficient in this regard. Thanks to its high - precision programming, it can minimize the amount of material removed during the machining process. The material waste in CNC machining is generally low, around 5 - 10%. In traditional machining, due to less precise tool - path control and the need for more trial - and - error adjustments, the material waste can be much higher, typically in the range of 20 - 30%.

- Consider the production of aluminum parts. In a traditional machining process for creating a complex - shaped aluminum bracket, a large amount of material might be wasted during the rough - cutting and finishing operations. The operator may need to remove more material than necessary to ensure the part's dimensions are correct, resulting in a high waste rate. In a CNC - machining process, the pre - programmed tool paths ensure that only the exact amount of material required is removed, reducing waste significantly. The comparison of material waste is presented in the Yigu Technology table below:

| Machining Method | Material Waste |

|------------------|----------------|

| CNC Machining | Low (5–10%) |

| Traditional Machining | High (20–30%) |

- Production Time

- CNC machining is much faster, especially for complex parts and prototypes. A prototype can be produced in a matter of hours using CNC machining. In traditional machining, creating the same prototype could take days or even weeks. For instance, in the development of a new smartphone prototype, the various components such as the chassis and internal brackets can be quickly produced using CNC machining. The CAD models can be rapidly translated into G - codes, and the CNC machine can start production immediately. In traditional machining, each part would need to be manually set up on the machine, and the operator would need to make multiple adjustments, leading to a much longer production time.

- For small - scale production runs, CNC machining also has an edge. While traditional machining may take a long time to set up for each part, CNC machines can quickly switch between different programs, allowing for faster production. The table below shows the approximate production times for different machining methods:

| Machining Method | Production Time for Prototypes | Production Time for Small - Scale Production |

|------------------|------------------------------|---------------------------------------------|

| CNC Machining | Fast (hours for prototypes) | Fast (can produce small batches in a short time) |

| Traditional Machining | Slow (days/weeks) | Slow (long setup times for each part) |

- Cost - Effectiveness

- The cost - effectiveness of CNC machining and traditional methods depends on various factors, including production volume and complexity. For high - volume production of simple parts, traditional machining may be more cost - effective in some cases as the initial investment in equipment is lower. However, for small - to - medium - volume production and complex part designs, CNC machining becomes more attractive. The precision of CNC machining reduces the need for rework, which can save significant costs.

- For example, in the production of a small batch of 100 complex - shaped metal parts, the cost of rework in traditional machining due to inaccuracies could be substantial. Each reworked part incurs additional labor and material costs. In CNC machining, the high - precision production reduces the rework rate, making it more cost - effective overall. The cost comparison can be summarized as follows:

| Machining Method | Cost for High - Volume Simple Parts | Cost for Small - Medium Volume Complex Parts |

|------------------|------------------------------------|---------------------------------------------|

| CNC Machining | Competitive for complex designs | Cost - effective with reduced rework |

| Traditional Machining | Cost - effective with low - cost equipment | Expensive due to high rework and labor - intensive process |

- Complexity of Shapes

- CNC machining is far superior when it comes to creating complex 3D shapes. With its multi - axis capabilities, it can produce parts with intricate geometries that are nearly impossible to achieve with traditional machining. Traditional machining is generally limited to basic forms and simple shapes. For example, in the production of a turbine blade for a jet engine, the complex airfoil shape and the internal cooling channels can only be accurately produced using CNC machining. Traditional machining methods would be unable to create the precise curves and internal features required for the blade's optimal performance.

- The table below further illustrates the difference in the ability to handle shape complexity:

| Machining Method | Ability to Handle Complex Shapes |

|------------------|----------------------------------|

| CNC Machining | Supports intricate 3D shapes |

| Traditional Machining | Limited to basic forms |

CNC Machining Finishes

The finish of a CNC - machined part is crucial as it can significantly impact the part's functionality, appearance, and durability. There are several types of finishes available, each with its own set of advantages and applications.

Anodizing

Anodizing is a popular surface treatment, especially for aluminum parts. It involves creating an oxide layer on the surface of the metal through an electrochemical process. This oxide layer provides enhanced corrosion resistance. In outdoor applications, such as aluminum alloy brackets used in solar panel installations, anodized finishes can protect the parts from the elements for years. The anodizing process also allows for color customization. For example, anodized aluminum parts can be dyed various colors, which is useful in applications where aesthetics matter, such as in consumer electronics or architectural components. There are different types of anodizing, including sulfuric acid anodizing, which is the most common and provides a hard, durable finish, and chromic acid anodizing, which is used in applications where the part needs to be electrically conductive.

Powder Coating

Powder coating is another widely used finish. It involves applying a dry powder, usually a mixture of resins, pigments, and additives, to the surface of the part. The powder is then cured under heat, forming a hard, protective coating. Powder - coated finishes offer excellent durability and resistance to scratches, chemicals, and UV radiation. In the automotive industry, powder - coated wheels are a common sight. They not only look attractive but also can withstand the harsh conditions of the road, including exposure to salts, mud, and debris. Powder coating is also available in a wide range of colors and textures, from smooth and glossy to matte and textured, allowing for a high degree of customization.

Electroplating

Electroplating is a process that deposits a thin layer of metal onto the surface of a workpiece. This can be used to improve the appearance of the part, enhance its corrosion resistance, or provide other properties such as improved electrical conductivity. For example, nickel plating is often used on brass parts to prevent tarnishing and provide a more attractive, shiny finish. Chrome plating is popular for its decorative and corrosion - resistant properties and is commonly seen on automotive bumpers and trim. In the electronics industry, gold plating is used on connectors to improve electrical conductivity and prevent oxidation. The thickness of the electroplated layer can be precisely controlled, allowing for different levels of protection and functionality. For instance, a thicker layer of nickel plating may be applied to parts that need to withstand more severe corrosion environments.

Polishing

Polishing is a mechanical finishing process that involves using abrasive materials to remove surface imperfections and create a smooth, shiny surface. It can be used on a variety of materials, including metals, plastics, and ceramics. In the jewelry industry, polishing is a crucial step in creating high - quality, visually appealing pieces. For Yigu Technology example, polished stainless - steel bracelets have a sleek, mirror - like finish that is highly desirable. In the medical device industry, polished surfaces on surgical instruments can reduce the risk of tissue adhesion and make the instruments easier to clean and sterilize. There are different levels of polishing, from rough polishing, which is used to remove significant surface defects, to fine polishing, which creates a near - perfect, mirror - like finish.

Conclusion

Yigu Technology CNC machining services have proven to be an indispensable part of modern manufacturing, offering a wide array of benefits that address the complex needs of various industries. From the high precision and consistency required in aerospace components to the rapid prototyping capabilities that fuel innovation in start - ups, CNC machining has transformed the production landscape.

The ability to achieve tight tolerances, as demonstrated by the ±0.001mm (or even tighter in some advanced setups) precision, ensures that parts meet the strictest quality standards. This precision not only enhances the functionality of the final products but also reduces the need for rework, leading to significant cost savings over time. The consistency in production also means that manufacturers can rely on CNC - machined parts to be identical, which is crucial for mass production and assembly processes.

The versatility of CNC machining in terms of materials is another key advantage. Whether working with metals like aluminum, stainless steel, and titanium or plastics such as POM, PEEK, and ABS, CNC machines can shape these materials into complex geometries with ease. This material flexibility, combined with the various surface finishes available, allows for the creation of parts that are not only functional but also aesthetically pleasing and durable.

In terms of efficiency, CNC machining stands out in both rapid prototyping and production. The ability to quickly turn a digital design into a physical prototype in as little as 1 - 3 days accelerates the product development cycle. For production, CNC machines can handle low - volume production runs cost - effectively, with batch sizes ranging from 10 to 10,000+ parts, making it suitable for market testing and small - to - medium - sized businesses.

When compared to traditional machining methods, CNC machining clearly has the upper hand in precision, material waste reduction, production time, and handling complex shapes. While traditional methods may still have a place in certain low - volume, simple - part production scenarios, CNC machining is the go - to choice for high - quality, complex, and time - sensitive manufacturing projects.

As technology continues to advance, we can expect CNC machining services to become even more efficient, precise, and versatile. With the integration of artificial intelligence and the Internet of Things, CNC machines may be able to optimize their own processes, predict maintenance needs, and communicate with other manufacturing systems in real - time. This will further enhance the capabilities of CNC machining, making it an even more powerful tool for industries worldwide.

In summary, if you are in need of high - precision parts, whether for prototyping or large - scale production, CNC machining services offer a reliable, efficient, and cost - effective solution. By leveraging the latest technology and the expertise of skilled professionals, CNC machining can bring your design concepts to life with the highest level of quality and accuracy.