Introduction

Precision machining, a high - end manufacturing technology, is crucial for producing components with extremely high accuracy and tight tolerances. It involves a series of advanced techniques and processes, such as precision cutting, grinding, and electrical discharge machining. In precision machining, the tolerance can reach the micron or even nanometer level, which is essential for industries like aerospace, automotive, and medical device manufacturing.

China has emerged as a global powerhouse in precision machining. In 2024, the global precision machining market size is substantial, and China contributes a significant portion to it. With a large - scale manufacturing base, a strong pool of skilled labor, and continuous investment in research and development, China has established a comprehensive industrial system for precision machining. This article will explore the various advantages of precision machining in China from multiple perspectives, aiming to help you better understand why China has become a preferred choice for many businesses in need of high - quality precision - machined components.

Advanced Technological Capabilities

State - of - the - Art Equipment

China's precision machining industry is equipped with a vast array of state - of - the - art equipment. High - precision CNC (Computer Numerical Control) machine tools are widely used. For example, some high - end five - axis 联动 CNC machine tools have an axis positioning accuracy of up to ±0.002mm. This high - precision hardware configuration allows the tool to accurately move along the preset path, enabling precise carving of tiny details in complex parts processing.

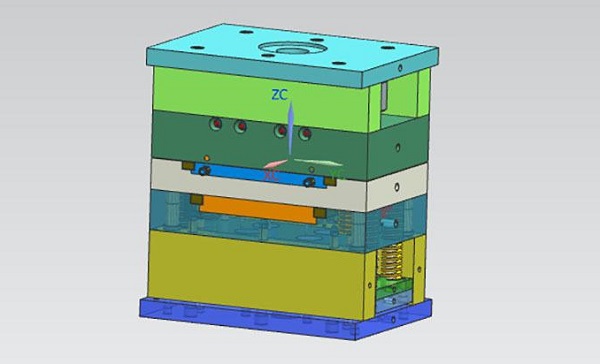

Electrical discharge machining (EDM) equipment also plays a significant role. EDM machines can achieve high - precision processing, with some models having a positioning accuracy of up to 3 microns and a minimum electrode loss ratio of 0.1%. This makes them suitable for processing complex - shaped parts with high precision requirements, such as in the aerospace and mold manufacturing industries.

High - tech Manufacturing Processes

Advanced manufacturing processes are the key to ensuring the high - quality output of precision machining. Micro - nano processing technology, which involves fabricating components at the micro and nano scales, has seen remarkable development in China. In semiconductor manufacturing, laser micro - nano processing technology has been widely adopted. For instance, in wafer - level semiconductor chip cutting, the traditional diamond cutting technology has a low efficiency, high cost, and a cutting accuracy of only about 50 microns. In contrast, the ultraviolet laser cutting technology used in China can achieve a cutting accuracy of up to 2.5 microns, with almost no debris, significantly improving the cutting efficiency and yield.

Ultra - precision grinding is another advanced process. Through the use of ultra - fine abrasive grinding wheels and strict process control, it can achieve extremely high - precision surface processing. For example, in the processing of optical components, ultra - precision grinding can control the surface roughness of the workpiece to Ra0.025 - Ra0.05μm, and the flatness of the mold plane can be controlled within ±0.001mm, meeting the high - precision requirements of high - end products.

Cost - effectiveness

Economies of Scale

China's large - scale manufacturing industry gives it significant economies of scale in precision machining. According to industry reports, in 2023, China's manufacturing output value accounted for nearly 30% of the global total. In the precision machining field, this large - scale production environment allows enterprises to purchase raw materials in large quantities. For example, when purchasing high - quality alloy steel for precision parts processing, large - scale Chinese precision machining enterprises can enjoy a 15 - 25% price discount compared to small - scale enterprises in some European countries.

Moreover, with the large - scale production, the fixed costs such as equipment depreciation and factory rent can be allocated to a larger number of products. A medium - sized precision machining factory in China with an annual production capacity of 500,000 precision components can reduce the unit fixed cost by about 30 - 40% compared to a factory with an annual production capacity of 100,000 components in a smaller - scale manufacturing country. This significant cost reduction makes the final price of precision - machined products more competitive in the international market.

Competitive Labor Costs

China has a relatively reasonable labor cost structure in the field of precision machining. Although labor costs have been rising in recent years, compared with developed countries, China still has a certain cost - advantage. For example, in 2024, the average hourly wage of precision machining workers in the United States is about \(25 - \)35, while in China, it is about \(8 - \)15.

However, it's important to note that this cost - advantage does not come at the expense of product quality. China has a large number of skilled workers in the precision machining industry. These workers have received professional training in vocational schools and on - the - job training in enterprises. They are proficient in operating advanced precision machining equipment and have a high level of technical skills. For example, in the processing of high - precision aerospace parts, Chinese workers can ensure the processing accuracy within the specified tolerance range while completing the processing tasks efficiently, achieving a balance between cost - effectiveness and product quality. This makes China an attractive choice for businesses that need high - quality precision - machined components at a reasonable cost.

Skilled Workforce

Professional Training System

China has established a comprehensive and well - developed professional training system for precision machining. Vocational schools and technical colleges play a crucial role in this system. In these educational institutions, students majoring in precision machining - related majors are offered a wide range of courses. For example, they learn basic mechanical engineering knowledge such as mechanical design, material mechanics, and mechanical drawing. At the same time, they also receive in - depth training in advanced precision machining techniques, including CNC programming, precision measurement, and advanced manufacturing processes.

Moreover, many vocational schools have established partnerships with leading precision machining enterprises. These enterprises provide practical training opportunities for students, allowing them to practice in real - world production environments. Some schools even introduce enterprise - based projects into the curriculum, enabling students to gain hands - on experience in actual precision machining projects from an early stage. This close combination of theory and practice ensures that students can master the skills required for precision machining quickly and effectively.

Rich Practical Experience

Chinese precision machining technicians have accumulated rich practical experience over a long period of development. In large - scale precision machining projects, such as the manufacturing of high - precision aerospace components, technicians often encounter complex processing requirements. For instance, in the production of aircraft engine blades, which require not only high - precision shaping but also strict control of material properties and surface quality.

Take a project in a well - known aerospace manufacturing enterprise in China as an example. The technicians faced the challenge of processing a new type of super - alloy aircraft engine blade. The complex curved surface of the blade required extremely high - precision multi - axis machining. Through continuous experimentation and improvement, the technicians optimized the processing parameters of the five - axis CNC machine tool. They adjusted the spindle speed, feed rate, and cutting depth according to the characteristics of the super - alloy material. After repeated trials, they successfully completed the processing of the blades, with the dimensional accuracy reaching ±0.005mm and the surface roughness controlled within Ra0.4μm, meeting the strict requirements of the aerospace industry. This case demonstrates the strong practical problem - solving ability of Chinese precision machining technicians, which is an important advantage in the global precision machining market.

Quality Control

Stringent Quality Standards

Chinese precision machining enterprises strictly adhere to a series of domestic and international quality standards. ISO (International Organization for Standardization) standards are widely implemented. For example, many enterprises have obtained ISO 9001:2015 certification, which requires the establishment of a comprehensive quality management system. This system covers all aspects of the production process, from the procurement of raw materials to the after - sales service of products.

In addition to ISO 9001, for industries with special requirements, such as the automotive industry, enterprises often comply with the IATF 16949 standard. This standard focuses on the quality management of automotive - related products, including requirements for product safety, production part approval process, and continuous improvement. By strictly following these international standards, Chinese precision machining enterprises can ensure that their products meet the high - quality requirements of the international market.

Comprehensive Quality Inspection

A comprehensive quality inspection process is carried out throughout the entire production cycle, from raw materials to finished products.

Raw Material Inspection: When raw materials enter the factory, strict inspections are carried out. For metal materials, the chemical composition is analyzed using spectrometers to ensure that it meets the specified standards. The physical properties such as hardness and tensile strength are also tested. For example, in the production of high - precision aerospace components, the acceptance rate of raw materials after inspection is required to reach over 99%. Only qualified raw materials can enter the production process.

In - process Inspection: During the machining process, regular inspections are carried out at each production stage. CNC machine tools are often equipped with on - line monitoring systems that can detect the machining accuracy in real - time. If any deviation is found, the machine can be adjusted immediately. For example, in the processing of high - precision shafts, the dimensional accuracy is inspected every 10 - 15 parts during the machining process. The in - process inspection pass rate is maintained at around 98%, which effectively prevents the production of a large number of unqualified products.

Finished Product Inspection: After the products are processed, a final comprehensive inspection is carried out. This includes dimensional inspection using high - precision measuring instruments such as coordinate measuring machines (CMMs). The surface quality is also carefully examined to ensure that there are no defects such as scratches or cracks. For complex components, functional tests are also carried out. In a precision machining factory that produces medical device components, the overall qualified rate of finished products can reach over 97% after strict inspection, which fully demonstrates the high - quality control level of Chinese precision machining enterprises.

Comparison with Other Countries

When comparing precision machining in China with that in other countries, the advantages of China become even more evident. The following table shows a comparison in terms of cost, precision, and production cycle:

| Comparison Items | China | Some Developed Countries (e.g., the United States, Germany) | Some Developing Countries (e.g., India, Vietnam) |

| Cost (Relative Index, with China as 100) | 100 | 130 - 180 (higher labor costs, higher raw material procurement costs in some cases) | 80 - 90 (lower labor costs but higher costs in terms of technology - related inputs) |

| Precision (Typical Tolerance Level) | Micron - level (e.g., ±0.005mm in many high - end products), some reaching sub - micron level in special cases | Generally micron - level (±0.003 - 0.005mm in high - end products), with high - end products reaching sub - micron level | Mainly millimeter - level in general production, with some enterprises starting to reach micron - level in recent years but not as widespread as in China |

| Production Cycle (for Medium - sized Precision Machining Projects) | 2 - 4 months | 3 - 6 months (longer due to more complex management processes and relatively less efficient supply chain in some cases) | 4 - 6 months (longer due to immature industrial chains and less advanced production management) |

From the table, it can be seen that compared with developed countries, China has a significant cost - advantage while maintaining high - level precision. Although some developed countries may have a slight edge in the highest - level precision in some special fields, China's overall precision level can fully meet the needs of most industries. In terms of the production cycle, China's relatively short cycle can better meet the market's demand for quick delivery.

Compared with some developing countries, China has a more advanced technological foundation and a more complete industrial chain, which enables it to achieve higher precision in precision machining. Although developing countries may have lower labor costs, their overall industrial level and technological capabilities still have a long way to go compared with China, resulting in a longer production cycle and lower precision in precision machining.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology highly recognizes the advantages of precision machining in China. The advanced technological capabilities enable us to handle complex designs with high precision. For example, when custom - manufacturing non - standard plastic components for a medical device, we can use the state - of - the - art EDM equipment in China to achieve micron - level precision, ensuring the components fit perfectly into the overall device structure.

The cost - effectiveness and large - scale production capacity allow us to offer competitive prices to our customers without sacrificing quality. We can also take advantage of the rich and skilled workforce in China to provide high - quality services, from initial design consultations to after - sales support. In terms of quality control, the strict quality standards and comprehensive inspection processes in China ensure that our custom - made products meet the highest requirements of our customers. In a nutshell, Yigu Technology is committed to leveraging these advantages to provide the best non - standard plastic metal products and services to our clients.

FAQ

What are the common materials used in precision machining in China?

In China, common materials for precision machining include aluminum alloys, stainless steels, and copper alloys. Aluminum alloys, known for their lightweight, good thermal conductivity, and high strength - to - weight ratio, are widely used in the aerospace and automotive industries. For example, in aircraft manufacturing, aluminum alloy components can reduce the overall weight of the aircraft, thereby improving fuel efficiency. Stainless steels, with excellent corrosion resistance and high strength, are suitable for applications in the medical and food processing industries. In medical device manufacturing, stainless - steel components need to maintain their integrity in a corrosive environment. Copper alloys, valued for their high electrical and thermal conductivity, are often used in the electronics industry for manufacturing components like connectors and heat sinks.

How does China ensure the precision of complex parts machining?

China ensures the precision of complex parts machining through multiple means. Firstly, advanced equipment such as high - precision CNC machine tools and EDM equipment are employed. These machines can achieve high - precision movements and processing, with some five - axis CNC machine tools having an axis positioning accuracy of up to ±0.002mm. Secondly, advanced manufacturing processes like micro - nano processing and ultra - precision grinding are utilized. For instance, in semiconductor manufacturing, laser micro - nano processing technology can achieve high - precision cutting of chips. Thirdly, strict quality control is implemented. Stringent inspection processes are carried out at every stage, from raw material inspection to in - process and finished - product inspection, to ensure that the machining accuracy meets the requirements.

Is the lead - time of precision machining in China shorter than that in other countries?

In many cases, the lead - time of precision machining in China is shorter. This is mainly because China has a complete industrial chain, which enables rapid procurement of raw materials and components. For example, in the supply of aluminum alloys for precision machining, China's large - scale aluminum production industry can ensure timely supply. Moreover, China's large - scale manufacturing base and high - efficiency production management systems contribute to high production efficiency. Many Chinese precision machining enterprises have optimized their production processes and schedules, reducing unnecessary waiting times and production cycles. Additionally, the rich and skilled workforce in China can complete processing tasks more efficiently, further shortening the lead - time compared to some other countries.