What is a Machining Part Factory?

A machining part factory for precision engineering is a specialized manufacturing facility that focuses on producing high - tolerance components. These components are crafted with extreme accuracy, often with tolerances in the micrometer range. Such factories play a crucial role in various industries, from aerospace and medical to electronics and automotive.

In the aerospace industry, for example, precision - engineered parts are used in aircraft engines. The smallest deviation in the dimensions of engine components can lead to significant performance issues, including reduced fuel efficiency and potential safety hazards. A machining part factory ensures that parts like turbine blades are manufactured with the utmost precision. These blades must have a consistent aerodynamic shape to optimize the engine's performance. The tolerance for these parts can be as low as ±0.001 inches.

In the medical field, precision - machined parts are used in surgical instruments and implants. A hip implant, for instance, needs to fit precisely into the patient's body to ensure proper functionality and long - term success. The surface finish and dimensional accuracy of these implants are critical. Implants are often machined to a surface roughness of less than 0.8 micrometers and with dimensional tolerances in the range of ±0.05 millimeters.

The factory is equipped with state - of - the - art machinery. High - precision CNC (Computer Numerical Control) machines are the backbone of the operation. These machines can be programmed to perform a wide range of operations, including milling, turning, drilling, and grinding, with an extremely high degree of accuracy. For example, a five - axis CNC milling machine can move the cutting tool and the workpiece in five different directions simultaneously, allowing for the creation of complex shapes with tight tolerances.

Skilled machinists are also an essential part of the factory. They not only operate the machines but also program them, ensuring that the design specifications are met. These professionals have in - depth knowledge of materials, machining processes, and quality control. They can troubleshoot any issues that arise during the machining process and make adjustments to ensure the production of high - quality parts.

Key Aspects of a Machining Part Factory in Precision Engineering

Advanced Equipment Arsenal

A precision machining part factory is equipped with a variety of advanced equipment. High - precision machining centers are the cornerstone of operations. For example, a five - axis machining center can perform complex operations with high accuracy. It can move the workpiece and the cutting tool in five different directions, which is crucial for creating intricate shapes. This multi - axis movement reduces the need for multiple set - ups, thereby decreasing errors and enhancing production efficiency. In a five - axis machining center, the typical positioning accuracy can reach ±0.001 mm, which is far beyond the capabilities of traditional three - axis machines.

CNC lathes are another essential piece of equipment. They are ideal for turning operations, where cylindrical parts are machined. With computer - controlled operations, CNC lathes can achieve extremely tight tolerances. For instance, they can maintain a diameter tolerance of ±0.0005 inches on small - diameter shafts. High - speed milling machines are also common in these factories. These machines operate at high spindle speeds, often reaching up to 40,000 RPM. The high - speed rotation of the milling cutter allows for faster material removal rates while maintaining high precision, making them suitable for machining soft materials like aluminum as well as harder alloys.

Skilled Workforce: The Human Element

Behind every precision - machined part is a skilled workforce. Machinists in a precision engineering factory must have a solid understanding of mechanical drawing. They need to be able to interpret complex blueprints with tolerances specified down to the micrometer level. For example, when manufacturing a part with a specified diameter of 10.000 ± 0.005 mm, the machinist must understand how to set up the machine to achieve this tight tolerance.

Programming skills are also vital. Since most modern machining equipment is computer - controlled, machinists should be proficient in programming languages such as G - code and M - code. They can write programs to control the movement of the machine tools, the speed of the spindle, and the feed rate of the cutting tools. In addition, they need to have in - depth knowledge of materials. Different materials, like stainless steel, titanium, and high - strength plastics, have unique properties that affect the machining process. For example, titanium is strong but also has a low thermal conductivity, which can cause heat to build up during machining. A skilled machinist knows how to adjust the cutting parameters to prevent overheating and ensure a high - quality finish.

Stringent Quality Control Measures

Quality control is the lifeblood of a precision machining part factory. One of the most commonly used tools for quality inspection is the coordinate measuring machine (CMM). A CMM can measure the dimensions of a part with high accuracy, often with a measurement uncertainty of less than 0.001 mm. It uses a probe to touch the surfaces of the part at various points and then calculates the dimensions based on the probe's position. For example, when inspecting a complex aerospace component with multiple holes and surfaces, the CMM can quickly and accurately measure all the critical dimensions to ensure they meet the design specifications.

Surface roughness testers are also employed to measure the texture of the machined surface. In precision engineering, surface finish is crucial as it can affect the functionality of the part. For example, in a hydraulic system, a rough - surfaced piston can cause leaks. The surface roughness is typically measured in micrometers (μm), and for high - precision parts, the surface roughness value can be as low as 0.1 μm. Visual inspection is another fundamental quality control method. Trained inspectors carefully examine the parts for any visible defects such as cracks, scratches, or porosity. In some cases, they may use magnifying glasses or microscopes to detect minute flaws.

Real - World Applications and Significance

Applications in Aerospace

In the aerospace industry, machining part factories for precision engineering are indispensable. For example, in the manufacturing of aircraft engines, components such as turbine blades, compressor disks, and engine casings are produced with extreme precision. Turbine blades, which are exposed to high - temperature and high - stress environments during engine operation, need to have a precise aerodynamic shape. A machining part factory uses advanced CNC machining techniques to ensure that the blades have a surface finish of around 0.2 - 0.4 μm and dimensional tolerances within ±0.005 mm. This high - level precision not only improves the engine's efficiency but also enhances its durability and reliability.

Moreover, the production of aircraft structural components also relies on precision machining. Wing spars, which are crucial for supporting the wings, are made from high - strength alloys. Machining part factories can achieve the required tight tolerances for these components, ensuring that they fit together perfectly during aircraft assembly. This precision is vital for the overall structural integrity of the aircraft, as any deviation could lead to catastrophic failures during flight. The aerospace industry's continuous pursuit of lighter, stronger, and more fuel - efficient aircraft drives the demand for even higher - precision machining in these factories.

Contributions to the Medical Field

In the medical field, precision - machined parts play a critical role in improving patient care. One of the most significant applications is in the production of surgical instruments. Scalpels, forceps, and endoscopes are all examples of surgical tools that require high - precision manufacturing. Machining part factories can produce these instruments with smooth surfaces and precise dimensions. For instance, the cutting edges of scalpels are machined to be extremely sharp and consistent, with a tolerance of less than ±0.01 mm. This sharpness and precision enable surgeons to perform delicate procedures with greater accuracy, reducing the risk of tissue damage and improving surgical outcomes.

Implant manufacturing is another area where precision machining is of utmost importance. Hip implants, knee implants, and dental implants must be manufactured to fit the patient's anatomy precisely. A hip implant, for example, is designed to replace a damaged hip joint. It needs to have a surface roughness of less than 0.8 μm to promote bone ingrowth and a dimensional accuracy within ±0.05 mm to ensure a proper fit in the hip socket. The use of advanced machining techniques in machining part factories allows for the production of implants that are biocompatible, durable, and can provide long - term functionality for patients. These precision - machined implants have significantly improved the quality of life for millions of people suffering from joint diseases or injuries.

Yigu Technology's Perspective

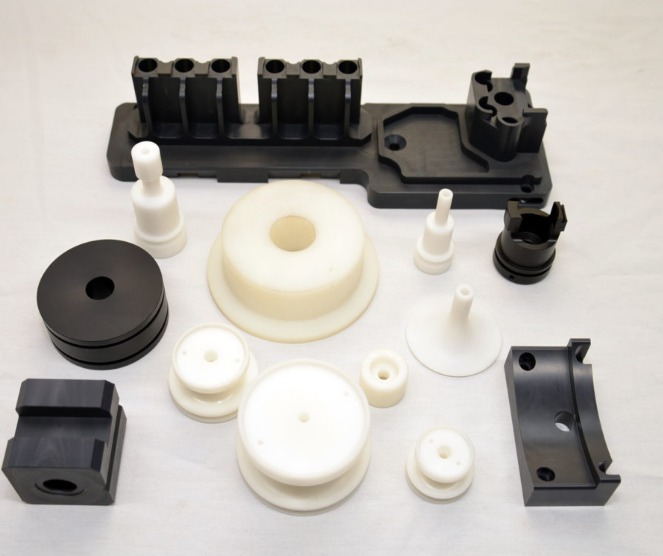

As a non - standard plastic and metal products custom supplier, Yigu Technology plays a significant role in the realm of precision engineering. We understand that every industry has unique requirements, and a one - size - fits - all approach simply won't cut it.

For clients in need of specialized plastic parts, we use advanced injection molding techniques. Our team can work with a variety of high - performance plastics, such as PEEK (Polyether - ether - ketone), which is known for its excellent heat resistance and mechanical properties. We ensure that the parts are molded with tight tolerances, often within ±0.05 mm, to meet the strict demands of applications like aerospace interiors or medical device components.

When it comes to metal products, we are proficient in machining different metals, including titanium alloys. Titanium is challenging to machine due to its high strength and low thermal conductivity. However, our skilled workers, equipped with state - of - the - art CNC machines, can overcome these difficulties. We can produce complex metal parts with surface finishes as smooth as 0.4 μm, which is crucial for applications where friction and corrosion resistance are essential, such as in the automotive and marine industries.

In essence, Yigu Technology is committed to providing customized solutions that bridge the gap between standard manufacturing and the specialized needs of precision engineering clients.

FAQ

What are the main differences between a general machining factory and a precision engineering machining part factory?

A general machining factory and a precision engineering machining part factory have several key differences. In terms of equipment, general machining factories often use standard machinery like basic lathes, mills, and drills. These machines have relatively lower precision, with positioning accuracies typically in the range of ±0.1 - ±0.5 mm. In contrast, precision engineering machining part factories are equipped with high - end CNC machines. For example, a five - axis CNC machining center in a precision factory can achieve a positioning accuracy of ±0.001 mm or even higher.

Regarding the manufacturing process, general machining factories usually adopt common machining techniques. They may have less complex programming for CNC machines, and the machining sequences are relatively straightforward. However, precision engineering machining part factories use advanced machining processes. They often require multi - axis machining to create complex shapes, and the programming for CNC machines is much more intricate, involving precise control of tool paths, spindle speeds, and feed rates.

The precision requirements also vary significantly. General machining factories are suitable for producing parts with looser tolerances, usually in the range of ±0.1 - ±1 mm. These parts are used in applications where high precision is not crucial, such as some basic automotive components or general - use mechanical parts. On the other hand, precision engineering machining part factories produce parts with extremely tight tolerances, often in the micrometer range (±0.001 - ±0.05 mm). These parts are essential for industries like aerospace, medical, and high - end electronics, where even the slightest deviation can lead to significant problems.

How does a machining part factory ensure the precision of its products?

A machining part factory for precision engineering ensures product precision through multiple means. First and foremost, regular equipment maintenance is crucial. High - precision CNC machines are serviced frequently. For example, the linear guides and ball screws of the machine are regularly inspected and lubricated to maintain their accuracy. Calibration of the machine's measuring systems is also carried out at regular intervals, often monthly or quarterly, to ensure that the machine's positioning and movement are precise.

Skilled personnel are another key factor. Machinists in these factories receive continuous training. They are trained to understand the latest machining techniques, new materials, and advanced programming methods. For instance, they are educated on how to program for different materials to optimize the machining process and maintain precision. Training programs may include workshops on new software for CNC programming and hands - on training with new types of cutting tools.

A strict quality - inspection process is implemented. Parts are inspected at various stages of production. In - process inspections are done after each major machining operation. Final inspections are carried out using advanced measuring equipment like coordinate measuring machines (CMMs). A CMM can measure the dimensions of a part with high accuracy, and any deviation from the design specifications is immediately identified. If a part does not meet the required precision, it is either re - machined or scrapped.

Can a machining part factory handle small - batch production for precision engineering?

Yes, a machining part factory can handle small - batch production for precision engineering. In terms of cost control, they use advanced software for accurate material planning. This software can calculate the exact amount of raw materials needed for a small - batch production run, reducing material waste. For example, it can optimize the layout of parts on a sheet of metal to minimize scrap.

The factory also has flexible manufacturing processes. CNC machines can be quickly reprogrammed for different part designs. The setup time for these machines is minimized through the use of modular fixtures. These fixtures can be easily adjusted and reconfigured to hold different workpieces, allowing for rapid change - overs between different small - batch production jobs.

Moreover, the factory's skilled workforce is an advantage. Machinists can troubleshoot and make real - time adjustments during the small - batch production process. They can handle any unexpected issues that may arise due to the unique requirements of small - batch production, ensuring that the precision of the parts is maintained even when producing a limited number of units.