CNC machining of AL2017 in T351 and T4 conditions comes with distinct challenges tied to their alloy composition and heat treatment histories. AL2017’s high copper content (3.5-4.5%) enhances its strength but also makes it highly abrasive, accelerating tool wear and reducing the lifespan of cutting tools compared to more machinable alloys like 6061. The T351 and T4 tempers exhibit unique machining behaviors: T351’s stress-relieved state offers better workability but retains significant hardness, while T4’s natural aging results in higher ductility, increasing the risk of chip adhesion to tools and poor surface finish. Both conditions are prone to work hardening; repeated cutting in the same area can raise material hardness by 10-15%, requiring frequent adjustments to machining parameters to maintain precision. Achieving tight dimensional accuracy is further complicated by their moderate thermal conductivity (120 W/(m·K)); uneven heat distribution during machining can cause subtle warping, affecting critical parts like aerospace components and automotive wheels. This guide addresses these pain points, offering expert strategies to master CNC machining of AL2017 T351/T4.

Material Overview of AL2017 T351/T4

AL2017 is a copper-based aluminum alloy known for its balance of strength and workability, with T351 and T4 conditions tailored for specific applications:

- Alloy composition: Contains 3.5-4.5% copper, 0.5-1% magnesium, 0.4-1% manganese, and trace elements, contributing to its high mechanical properties and machinability challenges.

- T351 condition: Produced via solution heat treatment, quenching, natural aging, and stress relief by stretching (1-3% elongation), making it readily available in sheet, plate, and bar forms for structural parts.

- T4 condition: Achieved through solution heat treatment, quenching, and natural aging (room temperature for 96+ hours), offering good formability and widely used in automotive manufacturing and consumer electronics.

- General characteristics: Both conditions combine high strength with moderate corrosion resistance, though they require protective coatings in harsh environments. T351 is preferred for parts needing stability after machining, while T4 suits applications requiring post-machining forming.

CNC Machining Techniques for AL2017 T351/T4

CNC machining techniques for AL2017 T351/T4 must be tailored to their temper-specific properties:

- Precision milling: T351 performs well with spindle speeds of 8,000-12,000 RPM and feed rates of 0.15-0.25 mm/tooth, using 4-flute carbide end mills to manage chip evacuation. T4 requires slightly higher speeds (10,000-15,000 RPM) to reduce chip adhesion, with feed rates of 0.12-0.2 mm/tooth to prevent burring.

- Turning operations: Suitable for cylindrical parts like shafts and bushings. T351 benefits from spindle speeds of 3,000-5,000 RPM and feed rates of 0.1-0.18 mm/rev, while T4 uses 3,500-6,000 RPM and 0.12-0.2 mm/rev to achieve smooth surfaces.

- Drilling processes: Carbide drills with 135° point angles and polished flutes prevent delamination. T351 tolerates continuous drilling with coolant flow rates of 15-20 L/min, while T4 requires peck drilling (0.5-1 mm increments) to avoid chip welding.

- Tool wear management: T351’s higher hardness increases flank wear by 20-25% compared to T4, requiring more frequent tool changes. Using TiAlN-coated carbide tools extends tool life by 30-40% for both conditions.

Heat Treatment Processes for AL2017 T351/T4

Heat treatment defines the unique properties of T351 and T4, directly impacting their machinability:

- T351 process:

- Solution heat treatment at 500-510°C for 1-2 hours to dissolve alloying elements.

- Water quenching to trap elements in a supersaturated solid solution.

- Natural aging at room temperature for 96+ hours to develop strength.

- Stress relief by stretching 1-3% to eliminate residual stresses, reducing machining warpage.

- T4 process:

- Same solution heat treatment and quenching as T351.

- Natural aging at room temperature for 96+ hours without stress relief, resulting in higher ductility but more residual stresses.

- Microstructure development: Both processes form fine copper-rich precipitates, with T351’s stress relief producing a more uniform grain structure, improving workability compared to T4’s slightly coarser grains.

- Hardness changes: T351 achieves 110-120 HB, while T4 reaches 100-110 HB, with hardness increasing by 5-10% during natural aging post-machining.

Material Properties of AL2017 T351/T4

The material properties of T351 and T4 dictate their machining requirements and application suitability:

- Mechanical properties: T351 offers tensile strength of 420 MPa, yield strength of 275 MPa, and 12% elongation; T4 provides tensile strength of 400 MPa, yield strength of 240 MPa, and 15% elongation, balancing strength and ductility.

- Hardness levels: T351 registers 110-120 HB, T4 100-110 HB—both harder than 6061, requiring robust cutting tools.

- Corrosion resistance: Moderate in both conditions, with susceptibility to pitting in saltwater, necessitating protective coatings for marine applications.

- Fatigue strength: T351 exhibits superior fatigue resistance (160 MPa at 10^7 cycles) due to stress relief, making it ideal for vibration-prone automotive parts.

- Thermal conductivity: 120 W/(m·K), requiring efficient coolant systems to prevent heat-induced defects during machining.

| Property | T351 Condition | T4 Condition |

| Tensile Strength | 420 MPa | 400 MPa |

| Yield Strength | 275 MPa | 240 MPa |

| Elongation | 12% | 15% |

| Brinell Hardness | 110-120 HB | 100-110 HB |

| Fatigue Strength (10^7 cycles) | 160 MPa | 150 MPa |

Applications and Industries for AL2017 T351/T4

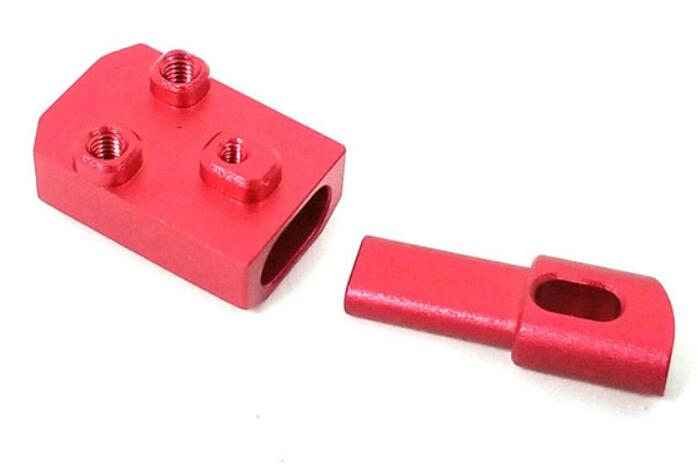

CNC machined AL2017 T351/T4 parts excel in diverse industries requiring strength and formability:

- Aerospace components: T351 is used for aircraft wing ribs, fuselage frames, and landing gear parts, while T4 suits interior structural components needing post-machining forming.

- Automotive manufacturing: T351 finds use in automotive wheels, suspension arms, and brake components, while T4 is ideal for engine brackets and transmission parts.

- Industrial machinery: T351’s stress relief makes it suitable for tooling plates and conveyor system components, while T4 suits parts requiring bending, such as machine guards.

- Marine applications: T351’s fatigue resistance benefits boat hull frames and hardware, with protective coatings enhancing corrosion resistance in saltwater.

- Consumer electronics: T4 is used for device enclosures and heat sinks, leveraging its formability and moderate thermal conductivity.

Quality Assurance for AL2017 T351/T4

Rigorous quality assurance ensures AL2017 T351/T4 parts meet industry standards:

- Inspection methods:

- Coordinate measuring machines (CMMs) verify dimensional accuracy to ±0.02 mm for critical features, with T351 requiring fewer adjustments due to its stress-relieved state.

- Non-destructive testing (NDT) including ultrasonic testing detects subsurface defects in aerospace components, while eddy current testing identifies surface cracks.

- Surface roughness: Profilometers check for Ra 0.8-1.6 μm, with T4 achieving smoother finishes more easily than T351, which may require secondary polishing to remove micro-chips.

- Standards compliance: Parts must meet ASTM B209 (sheet/plate) and AMS 4027 (T351) / AMS 4026 (T4) specifications, with certifications verifying heat treatment and alloy composition.

- Process validation: Statistical process control (SPC) monitors feed rates, spindle speeds, and tool wear, reducing part variation by 15-20% in high-volume production.

Yigu Technology's Perspective

Yigu Technology specializes in CNC machining AL2017 T351/T4, leveraging expertise in their unique properties. For T351, we use carbide tools with TiAlN coatings and optimized feed rates (0.15-0.2 mm/tooth) to balance productivity and surface finish. For T4, we employ sharp, polished flutes and higher spindle speeds (12,000-15,000 RPM) to minimize chip adhesion. Our precision milling and turning operations feature thermal compensation systems to maintain dimensional accuracy. Quality control includes CMM inspections and NDT, ensuring compliance with ASTM and AMS standards for aerospace components and automotive parts. We recommend T351 for high-stress structural parts and T4 for formable components, optimizing processes to deliver cost-effective, reliable results.

FAQ

- Which is more machinable: AL2017 T351 or T4?

T4 is more machinable due to its higher ductility and lower hardness, allowing higher feed rates and reducing chipping risk. T351’s stress relief improves stability but retains higher hardness (110-120 HB), requiring slower speeds and more frequent tool changes.

- How to prevent work hardening in AL2017 machining?

Minimize repeated cuts in the same area, use sharp carbide tools with polished flutes, and maintain spindle speeds of 10,000-15,000 RPM to reduce cutting time. Coolant flow rates of 15-20 L/min also help dissipate heat, preventing hardness increases.

- What surface treatments work best for AL2017 T351/T4?

Type II anodizing (20-30 μm thick) enhances corrosion resistance for general applications, while Type III hard anodizing (50-75 μm) suits high-wear parts like automotive wheels. For marine use, chromate conversion coatings provide additional saltwater protection.