Manufacturers producing parts with abrasive materials—like glass-filled plastics or metal powders—face a persistent challenge: mold components wear out quickly, leading to frequent replacements, production downtime, and inconsistent part quality. Even high-strength steels or copper alloys struggle to withstand the abrasive forces, with lifespans as short as 10,000-50,000 cycles in extreme cases. This is where tungsten carbide (YG8) transforms mold making. As one of the hardest and most wear-resistant materials available, YG8 tungsten carbide endures the harshest abrasive conditions, extending mold life by 5-10x compared to traditional materials. In this guide, we’ll explore how YG8 solves the critical pain points of high-wear molding, its unique properties, and how to leverage its capabilities for long-lasting, high-precision molds.

Introduction to Tungsten Carbide (YG8)

Tungsten carbide (YG8) is a composite material renowned for its exceptional hardness and wear resistance, making it ideal for the most demanding mold applications:

- Definition: YG8 is a tungsten carbide grade composed of tungsten carbide (WC) particles bonded together with 8% cobalt (Co). The “YG” designation (from the Chinese “Yin Gang,” meaning “tungsten steel”) indicates it’s a cobalt-bonded carbide, with “8” referring to the cobalt content percentage. This composition balances hardness with toughness, critical for withstanding impact and abrasion.

- Standard specifications: YG8 adheres to international standards (e.g., ISO 513) for cemented carbides, with strict controls on grain size (typically 1-5 μm) and cobalt distribution. This ensures consistent hardness (89 HRA) and compressive strength across batches.

- Supplier brands: Leading manufacturers include Sandvik (Sweden), Kennametal (USA), and Chinese suppliers like Zhuzhou Cemented Carbide Group. These brands produce YG8 in inserts, rods, and custom shapes optimized for mold components like cores, cavities, and wear plates.

- Industry usage: YG8 is used in 5-10% of high-wear molds, particularly in applications involving glass-filled plastics (20%+ filler), metal injection molding (MIM), and die casting of abrasive alloys. Its ability to withstand 500,000+ cycles in harsh conditions makes it a top choice for automotive and industrial part production.

- Comparison with other mold materials: YG8 outperforms all common mold materials in wear resistance—its hardness (89 HRA) is significantly higher than tool steel (60-65 HRC) and even high-strength copper alloys (350-400 HB). While it’s more brittle than steel, its wear resistance justifies the investment for abrasive applications, reducing replacement costs by 70-80% over time.

Properties of Tungsten Carbide (YG8)

The properties of tungsten carbide (YG8) make it unmatched for high-wear mold applications:

- High hardness: YG8 achieves a hardness of 89 HRA (equivalent to ~70 HRC), making it one of the hardest materials used in mold making. This hardness ensures it resists scratching, gouging, and wear from even the most abrasive materials, including 30% glass-filled nylon and aluminum die-casting alloys.

- High wear resistance: YG8’s wear resistance is 5-10x greater than tool steel and 20x greater than aluminum. In abrasive wear tests, it loses only 0.1-0.3 mm of material per 100,000 cycles, compared to 1-3 mm for steel under the same conditions.

- Good compressive strength: With a compressive strength of 4,000-4,500 MPa, YG8 withstands high molding pressures (up to 30,000 psi) without deformation, critical for maintaining dimensional accuracy in high-volume production.

- Low coefficient of thermal expansion: YG8 has a thermal expansion coefficient of 5.5-6.5 μm/m-°C, much lower than steel (11-12 μm/m-°C) and aluminum (23-24 μm/m-°C). This stability minimizes dimensional changes during temperature cycles, ensuring part consistency.

- Toughness: While YG8 is more brittle than steel, its 8% cobalt binder provides sufficient toughness to resist fracture in low-impact applications. It’s less prone to chipping than higher-hardness carbides (e.g., YG6 with 6% cobalt), making it versatile for most mold components.

- Chemical composition: The 92% tungsten carbide and 8% cobalt blend is key to YG8’s performance. Tungsten carbide provides hardness, while cobalt acts as a ductile binder, distributing stress and preventing catastrophic failure.

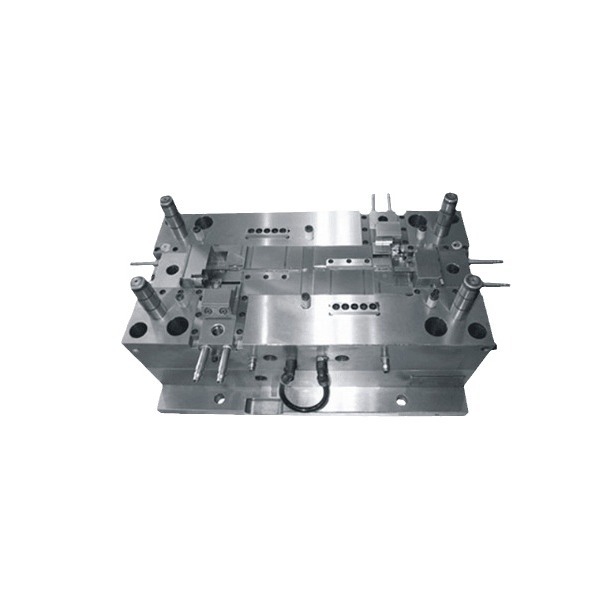

Applications of Tungsten Carbide (YG8) in Mold Making

Tungsten carbide (YG8) excels in applications where abrasion and wear are the primary failure modes:

- Injection molding for abrasive plastics: YG8 inserts are critical for molds producing parts with 20%+ glass, mineral, or carbon fiber fillers. These inserts (e.g., gate areas, core pins) withstand the abrasive flow of molten plastic, maintaining surface finish and dimensional accuracy for 500,000+ cycles.

- Die casting: In aluminum and zinc die casting, YG8 components (e.g., shot sleeves, plunger tips) resist wear from molten metal and oxides, outlasting steel by 5-8x and reducing downtime for replacements.

- High-precision molds: For micro-molding applications (e.g., medical micro-components, electronics connectors), YG8’s low thermal expansion and high hardness ensure tight tolerances (±0.0001 inches) are maintained over long production runs.

- Automotive molds: YG8 is used in molds for automotive parts like intake manifolds and structural components, which often use glass-filled plastics for strength. Its wear resistance reduces tooling costs for high-volume production (100,000+ parts).

- Metal injection molding (MIM): In MIM, where metal powders are molded and sintered, YG8 molds withstand the abrasive flow of metal-filled feedstocks, ensuring consistent part quality and extending mold life.

Machining and Fabrication of Tungsten Carbide (YG8)

Machining and fabrication of YG8 require specialized techniques due to its extreme hardness:

- Precision machining: YG8 cannot be machined with traditional tools—diamond tools are mandatory. Diamond grinding wheels, drills, and end mills are used to shape the material, with slow cutting speeds (5-15 SFM) to avoid tool damage.

- CNC milling: CNC milling of YG8 uses diamond-coated carbide tools or electroplated diamond end mills. Rigid machine setups are critical to prevent vibration, which can cause tool chipping and poor surface finish.

- EDM (Electrical Discharge Machining): EDM is the most efficient way to machine complex geometries in YG8. Wire EDM achieves tight tolerances (±0.0001 inches) and fine surface finishes (Ra 0.1-0.2 μm), making it ideal for intricate mold details.

- Grinding: Diamond grinding wheels (120-400 grit) are used for final shaping and surface finishing. Coolant is essential to dissipate heat, as excessive temperatures can weaken the cobalt binder and reduce toughness.

- Surface finishing: YG8 polishes to a smooth finish (Ra 0.05-0.1 μm) with diamond pastes (3-6 μm). This ensures the mold surface doesn’t scratch the part, critical for cosmetic applications.

- Machining challenges: The primary challenge is tool wear—diamond tools wear 5-10x faster than when machining steel. Additionally, YG8’s brittleness requires careful handling to avoid chipping during machining and assembly.

Maintenance and Repair of Tungsten Carbide (YG8) Molds

Proper maintenance and repair maximize the lifespan of YG8 molds, which can exceed 1 million cycles with care:

- Mold cleaning: Clean YG8 surfaces with soft brushes and mild solvents to remove plastic or metal residue. Avoid abrasive cleaners, which can damage the surface and reduce wear resistance.

- Surface treatment: A thin diamond-like carbon (DLC) coating can further enhance YG8’s wear resistance, extending life by 20-30% in extreme applications. This is particularly useful for molds running 30%+ glass-filled plastics.

- Repair welding: YG8 cannot be welded with traditional methods due to its high melting point. Instead, damaged areas are repaired by bonding new YG8 inserts using high-strength adhesives or brazing with silver-based alloys.

- Preventive maintenance: Inspect YG8 components monthly for chipping or cracks, especially in high-impact areas like mold parting lines. Replace worn inserts before they cause part defects.

- Inspection: Use optical microscopy to check for surface wear or micro-cracks, which can propagate and cause catastrophic failure. Ultrasonic testing detects internal defects in large YG8 components.

Yigu Technology’s Perspective

As a leading custom manufacturing supplier in China, Yigu Technology recommends YG8 tungsten carbide for clients facing extreme wear challenges. We’ve seen it extend mold life from 50,000 cycles (with steel) to 500,000+ cycles in 30% glass-filled plastic molds, drastically reducing downtime. While YG8’s machining costs are 3-4x higher than steel, its long-term savings are undeniable. Our team uses advanced EDM and diamond grinding to achieve precise YG8 components, ensuring seamless integration with steel molds. For high-volume, abrasive applications, YG8 is the only cost-effective solution—its performance justifies the investment in tooling and machining.

FAQs

- Can YG8 tungsten carbide be used for low-volume mold applications?

YG8 is rarely cost-effective for low-volume runs (<50,000 cycles) due to its high machining costs. Steel or copper alloys are better choices here. Reserve YG8 for high-volume, abrasive applications where its wear resistance delivers long-term savings.

- Is YG8 suitable for molds requiring impact resistance?

YG8 has moderate toughness but can chip under high impact (e.g., sudden mold closure). For impact-prone applications, use a lower-hardness carbide grade (e.g., YG10 with 10% cobalt) for better toughness, though wear resistance will be slightly reduced.

- How does YG8 perform in high-temperature molding applications?

YG8 maintains its hardness and wear resistance at temperatures up to 500°C (932°F), making it suitable for high-temperature plastics (e.g., PEEK) and die casting. Above 600°C, the cobalt binder softens, so avoid prolonged exposure to extreme heat.